Advancing the role of additive manufacturing in rail

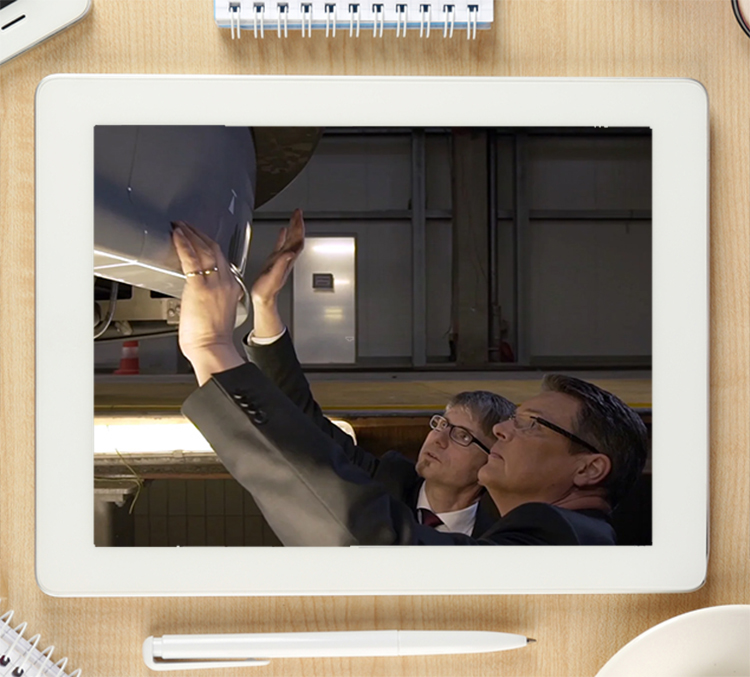

The adoption of 3D printing, also known as additive manufacturing, in the rail sector has grown over recent years, but how effective is this technology and what true benefits does it bring? Speaking to Craig Waters, Editor of Global Railway Review, Stefanie Brickwede, Head of Additive Manufacturing at Deutsche Bahn…