WiRailCom…an extensible framework for wireless monitoring

Posted: 25 November 2014 | | No comments yet

The provision of remote condition monitoring is evolving from asset-centric, hardwired/mains powered legacy systems to generic, light-weight, ad-hoc wireless systems that promote ubiquitous monitoring…

The provision of remote condition monitoring is evolving from asset-centric, hardwired/mains powered legacy systems to generic, light-weight, ad-hoc wireless systems that promote ubiquitous monitoring. Companies, such as Senceive, recognised the opportunity and have developed market leading monitoring equipment specifically targeted at the railway sector. The WiRailCom (WIreless RAILway COndition Monitoring) project aims to extend current functionality to offer an extensible framework architecture; encompassing flexible distributed intelligence with truly wireless design achieved through energy harvesting and local power management. Richard Lewis – Technical Project Manager for WiRailCom, explains more.

Retrofitting condition monitoring systems to rolling stock and infrastructure offers a number of benefits for operators and maintainers; from fault detection and asset management to knowledge acquisition and decision support. Prior to the maturing of wireless protocols for sensor integration these opportunities were prohibited by the cost and complexity of installing power and communications cabling to support monitoring equipment. A wide array of wireless hardware, which is underpinned by open communications protocols such as IEE 802.15, offer potentially ubiquitous monitoring capability. Due to the terrain, environment and the difficulties of installing and maintaining cabling, the railway has become a focus for wireless technology uptake.

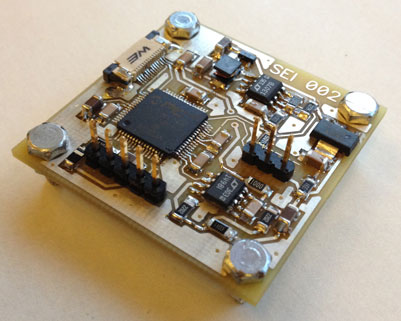

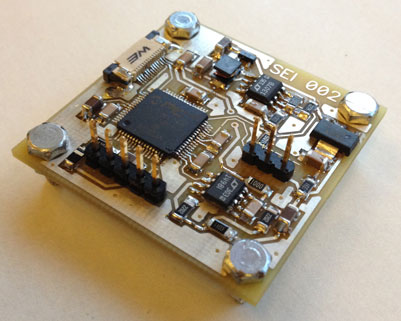

WiRailCom sensor module

During their undertakings a number of small and medium-sized enterprises (SMEs) established a common interest in investigating the potential of available wireless technologies to support condition monitoring. Westfälische Lokomotivfabrik Reuschling GmbH & Co. KG (Germany), maintains freight locomotives and was looking for a solution to retrofit a monitoring node as part of a customer upgrade. BK Telematics (Greece) was providing solutions to the automotive sector and was seeking to enhance its market. Senceive was providing a unique, mesh sensor network for railway infrastructure monitoring and was seeking to broaden its product base. Airtren (Spain) were working with infrastructure stakeholders and were looking for opportunities to extend its support to the infrastructure market. The EUs funding mechanism for SME support was identified as an appropriate mechanism for joint research. TWI, the University of Birmingham and MERMEC were subsequently identified as collaborative partners with capability to support the development work and the WiRailCom concept was born (www.wirailcom.eu).

The project

The apparent barrier to the uptake of totally wireless monitoring solutions is the maturity of available energy harvesting modules. WiRailCom aimed to deliver a harvester and power management unit specific to the requirements of the applications under analysis. The aim was to demonstrate gearbox and bearing fault detection and diagnosis over a completely cable-free arrangement. One aim was to understand how the network was utilising power in different arrangements and environments so that the harvester could be designed around the application. The project also investigated tuned mass harvesters and thermoelectric generators using energy management devices from original equipment manufacturers (OEMs). This research resulted in a number of circuit designs for efficient harvesting from vibration and thermal sources. It was subsequently demonstrated that sufficient energy could be harvested to support significant levels of monitoring and processing. A prototype module was developed that required minimal levels of alteration to the assets and virtually no downstream maintenance. This prototype system provided the partners with the opportunity to experiment with and extend defect detection and diagnosis capabilities.

Railway gear box test bed

Interoperability

One of the motivations of the project was to address the subject of interoperability. The partners were aware of the industry stakeholders’ drive to maximise the benefits from condition monitoring solutions through data integration and interoperability at the interfaces. The partners were keen to demonstrate that a generic wireless ‘backbone’ could provide a ‘plug and play’ capability, allowing the user to choose from an array of sensor modules without significant adjustment or reconfiguration of the network. This was an approach that Senceive were already looking at. As such, Senceive became an important contributor to the project; providing essential expertise on the area of wireless mesh networking.

Flexible system architecture

Wireless Mesh networks are built on IEEE 802.15.4 standards for wireless communication. One advantage of mesh networks is the ability to maintain a single point of contact between the network and higher level architecture. The mesh network then represents an array of self-organising and self-healing nodes that cooperate to deliver the monitoring functions. This was proposed as a major advantage for railway rolling stock applications where the network configuration might vary due to vehicle changes and the environment may impact on the operation of the network. Network function can also change depending on the user’s requirements and the proposed extensible approach was seen as an important feature for infrastructure monitoring where various and numerous asset types demand different transducer types and alternatives in processing capability. Providing an extensible framework as a solution, allowing the user to configure the network to suit their needs, was considered to be a key selling point of the project.

An extensible architecture was devised that separated the monitoring function from the network function. The interface to the sensor is generic, allowing the user to select the sensor function to suit their application. This was achieved through the development of a sensor module that was independent of the network module. This also offered greater flexibility in power management since the power to network and monitoring nodes can be controlled independently. This approach created additional flexibility, allowing a node to function as a sensor or simply a communication point to ensure data can navigate to the gateway. WiRailCom sensor modules were developed that comprise a network communications node, condition monitoring module, and power management module. Flexibility was achieved through use of an embedded 32-bit microcontroller.

WiRailCom architecture showing the network communications node, condition monitoring module, and power management.

Condition monitoring applications

To demonstrate the capability of the prototype system, a number of monitoring applications were devised for demonstration. Vibration analysis is a well-known monitoring technique used to identify bearing faults. This can be carried-out on data collected from an accelerometer or other vibration sensors. Frequency analysis is most commonly used to characterise bearing faults, so sampling rates over 20 thousand Samples per second Ss-1 are usually required, which results in large datasets. Preventative maintenance by monitoring the vibration of axle box bearings is a scientific approach that has shown significant potential in maintenance management. Even new rolling element bearings generate some acceptable level of vibration. Increments in vibration levels are usually symptoms of abnormal machine performance.

Conventionally, bearing condition monitoring relies on cabling connecting accelerometers on the bearing to a monitoring system where data is post-processed and integrated. The sensors are generally active devices that require power from the vehicle power systems. One restriction for the application of wireless vehicle inspection is that a lower power budget is available. In an arrangement where there are microprocessors in the system, active power management can be utilised. Essential ingredients of effective power management are the capability to select the duty cycle of the monitoring system, coupled with the ability to control and synchronise the components of the system. In addition, lessons were learnt regarding the computational load which dictates power consumption. Early prototype processing using envelope analysis and Empirical Mode Decomposition (EMD) techniques where deployed for processing the acquired condition monitoring signals. However, this was found to be too computationally expensive for the microcontroller. To reduce the computational load, an effort was made to identify key frequency ranges in which faults demonstrate the highest value of Kurtosis. A combination of Kurtosis processing and filtering methods were deployed via the embedded microcontroller in the monitoring and sensor module.

The subsequent results demonstrated that, in test conditions, significant defect detection and diagnosis was achieved for varying fault levels. The equipment developed in the project allowed the partners to experiment with various monitoring algorithms using a test bearing rig.

Concluding remarks

Typical modern rolling stock systems incorporate built-in condition monitoring capability. The benefits of such systems are attained through close incorporation of the component systems with vehicle infrastructure, including core data communication buses and train management units. Similar benefits may be obtained through retrofitting condition monitoring systems to existing rolling stock. However, installing such systems is prohibited by the cost and complexity of installing power and communications cabling to support the monitoring equipment. The advancements in wireless communication, localised processing capacity and energy harvesting as demonstrated in the WiRailCom project shows the opportunity to assess the condition of the vehicle at reduced cost and without the complexity of installing cabling. The WiRailCom solution is portable, cable-free, and enables user configurable sensing applications to facilitate temporary and semi-permanent monitoring. The monitoring solution is based on an extensible framework, which is robust enough to cope with network changes (e.g. loss of communication nodes due to vehicle change and environmental impact). During the closing stages of the project the partners have successfully demonstrated the potential benefits of the proposed approach. The consortium is now seeking to commercialise the results.

Biography

Richard Lewis, WiRailCom/ TWI Technology Centre (Wales)

Dr Richard Lewis is a Principal Project Leader at TWI Technology Centre (Wales). Having previously worked in manufacturing and academic research establishments, Richard has over 15 years’ experience of research, project delivery and technical management. Richard currently specialises in non-destructive testing (NDT), leading a number of research and development projects including condition monitoring and NDT inspection in railway infrastructure and rolling stock, as well as other industry sectors. Richard is the Technical Project Manager of the WiRailCom project.