Digital solution partnership agreed to boost rail freight reliability

Posted: 14 January 2022 | Global Railway Review | No comments yet

An agreement between Hitachi Rail and Intermodal Telematics (IMT) will see monitoring sensors fitted to rolling stock so rail freight companies can monitor operations in real-time to improve efficiency and safety of services.

Hitachi Rail and Netherlands-based independent telematic solution provider, Intermodal Telematics (IMT), have agreed an exclusive long-term partnership that will add IMT’s pioneering monitoring sensors to Hitachi’s existing digital freight service. The agreement will allow Hitachi to offer rail freight companies around the world a solution that provides real-time monitoring to improve efficiency and safety.

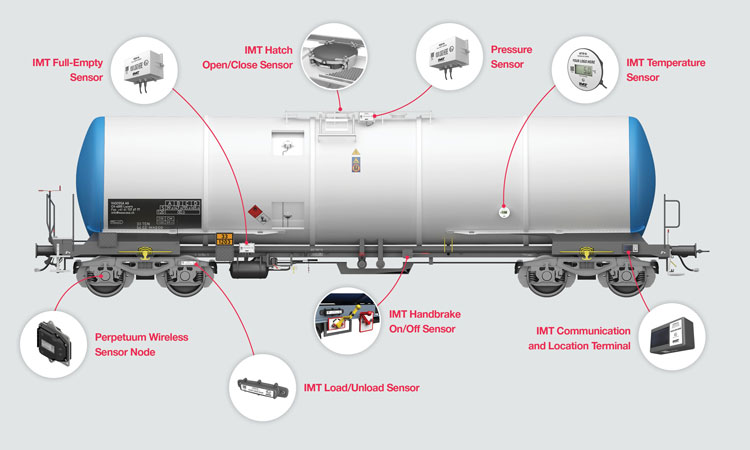

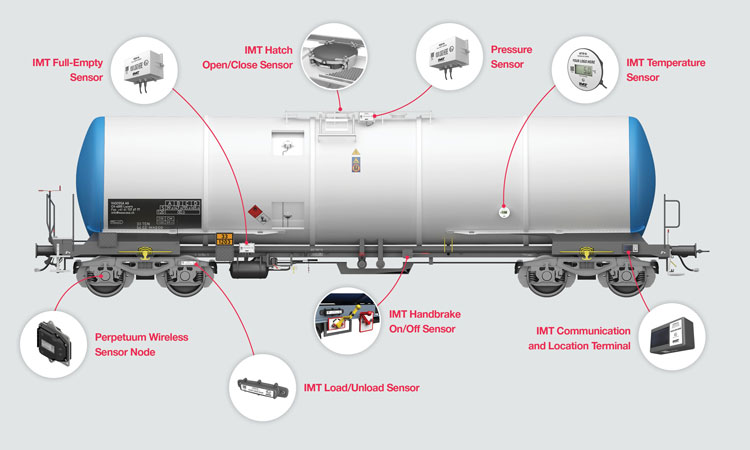

IMT digital monitoring sensors and telematics solutions can verify the exact location of freight cars, the loading status, the open/close condition of doors and hatches, the temperature and pressure of the cargo and the health condition of bogies and wheelsets. The data is then sent to the Cloud via a solar powered GPS device which allows the condition of the train and its cargo to be monitored in real-time, as well as alerting operators about potential issues. The partnership allows the use of AI analytics to optimise the efficiency and safety of its customers’ freight services worldwide.

The technology will allow Hitachi to provide fully-fledged telematics solutions that improve reliability and performance for the freight market. The technology can give companies the vital information they need to control their supply chains more efficiently and respond with appropriate interventions more quickly. With global supply chains having faced major disruption throughout 2021 and challenges predicted to continue, the partnership offers enhanced resilience for companies transporting goods via rail freight.

The partnership with will complement Hitachi Rail’s purchase of Perpetuum in 2021, who provide Hitachi with digital solutions that improve train reliability and performance. Its remote condition monitoring detects emerging damage in train bogies long before it can be identified by other means, thus preventing failures, facilitating more efficient maintenance cycles, and increasing the life of the wheels. Coupled with the IMT solution, Hitachi will now be able to completely monitor freight vehicles in real-time.

“Hitachi Rail is focused on growing its digital offer to develop data-driven solutions to meet our customer’s complex challenges,” explained Edoardo La Ficara, Executive Officer and Chief Operating Officer for Operation, Service & Maintenance at Hitachi Rail. “Our exclusive partnership with IMT delivers this and enables Hitachi to provide an enhanced digital freight offer across the globe, with a strong initial focus on European and North American markets.

“This solution will enable operators and maintainers to be aware of vehicles’ position and status at all times. This will provide a radical evolution for the freight industry, whose railcars are overwhelmingly without any telematics or monitoring whatsoever.”

IMT will now exclusively offer the Perpetuum sensor solution in the freight market, which will further broaden IMT’s full portfolio in asset and cargo monitoring for the international rail market.

Dethmer Drenth, Managing Director and Founder of IMT, said: “This partnership adds a significant value to our railcar market offering as we expand our renowned assets and cargo related monitoring to specific predictive asset maintenance monitoring with the Hitachi/Perpetuum sensor. In that way we create a holistic view of the railcar above and below the axle, alerting the asset and cargo owner on a need-to-know and managing-by-exception basis.”

The partnership’s initial focus for the new digital service will be in European and North American markets.

Example of Hitachi Rail & IMT’s full digital freight monitoring service. Credit: Hitachi Rail

Related topics

Artificial Intelligence (AI), Big Data, Cargo, Freight & Heavy-Haul, Digitalisation, Technology & Software