Measuring and modelling safety risk on GB’s mainline railways

Posted: 17 September 2010 | | No comments yet

The mainline railway in Great Britain has a responsibility to understand and measure safety risk to be able to manage safety of its operations properly. However, the task of quantifying levels of safety meaningfully can be difficult, especially for those rare accidents with potential for serious consequences. RSSB’s Safety Risk Model provides a solution to the problem and is a vital component of the GB railway safety management system.

The mainline railway in Great Britain has a responsibility to understand and measure safety risk to be able to manage safety of its operations properly. However, the task of quantifying levels of safety meaningfully can be difficult, especially for those rare accidents with potential for serious consequences. RSSB’s Safety Risk Model provides a solution to the problem and is a vital component of the GB railway safety management system.

The mainline railway in Great Britain has a responsibility to understand and measure safety risk to be able to manage safety of its operations properly. However, the task of quantifying levels of safety meaningfully can be difficult, especially for those rare accidents with potential for serious consequences. RSSB’s Safety Risk Model provides a solution to the problem and is a vital component of the GB railway safety management system.

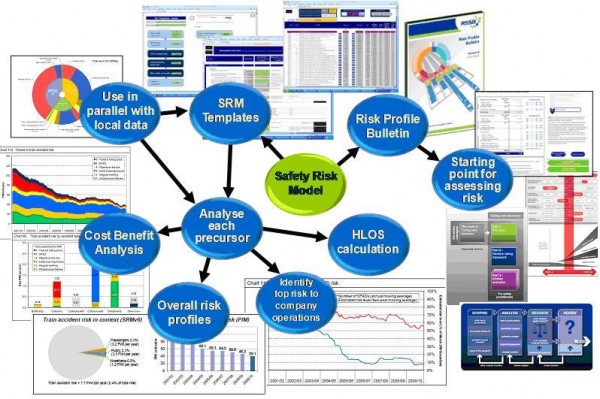

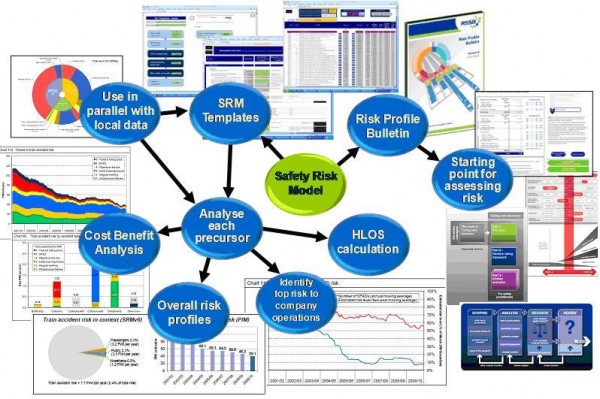

The GB railway is a complex system and all the companies that are part of it share a common purpose; they are seeking to deliver a safe, reliable and environmentally friendly railway while at the same time offering value for money. In this context, RSSB works with its members to support the development of safety strategies, set standards, and monitor and report on the safety performance of the industry as a whole. An understanding of the overall level of safety risk of the railway is a key foundation for this role and RSSB supports its members by providing risk information to help them benchmark their performance; this in turn helps them formulate their own safety policies, plans and measures. The RSSB Safety Risk Model (SRM) provides a network-wide risk assessment which is communicated to the industry in a range of ways, the primary one being in a Risk Profile Bulletin (RPB), which is periodically updated and published to members.

Where did the Safety Risk Model come from?

As part of the privatisation of the railway industry in Great Britain in the mid-1990s, a Safety Case regime was developed to manage responsibilities in the many resulting organisations. This also followed recommendations after a number of high profile incidents at the end of the 1980s, such as the Clapham Junction train collision in 1988, in which 35 people died and nearly 500 were injured1 and the Piper Alpha oil rig explosion, also in 1988, in which 167 died2. The new Safety Case regime required a risk assessment approach to demonstrate appropriate understanding and management of risk by each duty holder. Review of the initial Safety Cases in the late 1990s by Railtrack’s Safety and Standards Directorate led to the recommendation for a more sophisticated and robust approach to risk assessment by the then Infrastructure Manager, Railtrack. Lessons were also learnt by looking at how other industries (such as the nuclear, chemical, and oil and gas industries) implemented a risk based approach to managing safety.

The task of developing the first industrywide risk assessment lay initially with Railtrack. Following the accident at Ladbroke Grove in 19993, it was subsequently picked up by the independent rail industry safety organisation ‘Railway Safety’, formed in September 2000, and who published the first version of the ‘Safety Risk Model’ in January 2001.

The most recent version of the SRM was published in June 2009 by RSSB (the successor of Railway Safety) on behalf of the GB mainline railway, under the direction of a practitioners working group consisting of industry nominees from RSSB members.

Safety Data – a strong foundation

The basis for any robust risk assessment is of course good quality data. The Safety Risk Model uses safety and failure data from many sources but principally from the GB rail industry Safety Management Information System (SMIS). This is a national IT system managed by RSSB for the industry, which records all safety related events that occur on the mainline railway.

SMIS was introduced in 1997 to replace several separate systems and combine them into one central safety database. The merged data contains some information going back to 1973 and in total includes over 1.7 million records. This invaluable bank of safety records is the industry’s main source of data for safety performance monitoring and the Safety Risk Model, as well as a range of other RSSB outputs such as the Annual Safety Performance Report. Despite the wealth of available safety data, expert judgement and modelling expertise are always required to interpret the data in order to produce meaningful risk results.

What exactly is the Safety Risk Model?

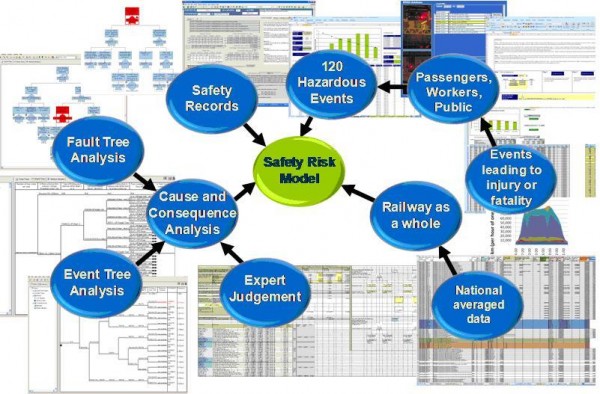

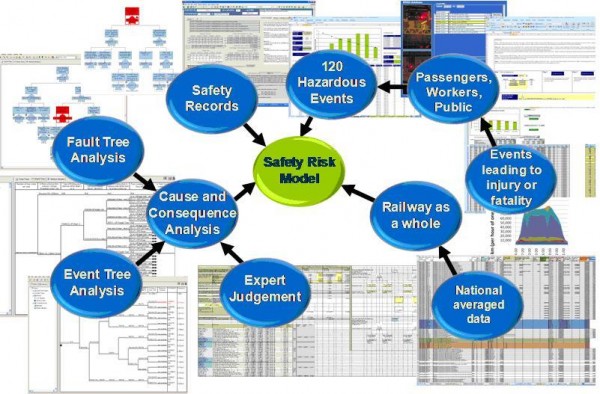

The Safety Risk Model is owned and maintained by RSSB and represents 120 hazardous events, which are further broken down into over 2000 low level precursors. It has been designed to take account of events occurring routinely (for which there is a significant quantity of recorded data), and also those events which occur rarely (where there is little recorded data). Where sufficient data is available, normal statistical analysis can be used. However, for low frequency events, where there is limited data, a series of fault and event tree4 models are used. Collectively, the 120 individual models define the overall level of risk on the mainline railway and provide a structured representation of the causes and consequences of all potential accidents arising from railway operations and maintenance. Since the initial version of the model, the basis of data has been refined using a variety of sources such as technical studies, expert judgement workshops, human factors analysis, technical failure data, and the continually updated GB Safety Management Information System.

Results of the model are presented in terms of risk to passengers, workforce, and members of the public and cover risk due to train accidents – such as train collisions, other accidents involving trains – such as boarding and alighting trains, and accidents unconnected with the movement of trains – such as a passenger falling on a station platform. The important factor in the SRM modelling is the calculation of frequency of hazardous events in combination with the consequences of each event; this gives the level of risk, measured in number of fatalities and weighted injuries (FWI5) per year.

Development of the Safety Risk Model

The Risk Profile Bulletin

As a result of the Safety Risk Model analysis, RSSB is able to produce for its members the complete GB mainline rail risk profile – a summary of the risk data for the 120 hazardous events. This supports RSSB’s members in studying, analysing and ultimately understanding the level of risk associated with their operations.

Each time the Safety Risk Model is revised and updated, an associated Risk Profile Bulletin is published. This is made available to members, along with other risk assessment resources, through the RSSB Risk Portal.

The total risk from the 120 hazardous events is assessed in the latest SRM to be 141.3 FWI/year (excluding suicides). This is made up of 67 fatalities/year, just over 500 major injuries and over 12,000 minor injuries, where risk to members of the public is largely fatality risk and the risk to the workforce and passengers is largely in the form of injuries. Some examples of the kind of information that can be extracted from the Safety Risk Model include:

- Member of public risk still forms the greatest proportion of the total risk, at 57.2 FWI/year (70% of which is due to trespass incidents)

- The group of hazardous events that presents the highest risk to passengers is slips, trips, and falls, which contributes 25.4 FWI/year, or 47% of the overall risk to Passengers

- The greatest workforce risk also comes from the slips, trips, and falls event type, with the second highest contribution coming from struck/crushed by large object/structure

- Train accidents have seen a 21% reduction in risk since the previous version of the SRM. This large reduction in risk is largely due to a reduction in the frequency of derailments

- The risk of a passenger or member of the workforce being killed in a train accident has reduced by over 80% in the last 10 years.

Uses of the Safety Risk Model

As has been highlighted already, the Safety Risk Model provides an understanding of the current risk on the mainline railway. The safety data is used in risk assessments, appraisals, and decision taking processes throughout the railway industry. These include ALARP (‘As Low As Reasonably Practicable’) assessments under the UK Health and Safety at Work (etc) Act 1974, and cost-benefit analyses, which are carried out to support decisions taken, for instance, about the addition of new risk reducing control measures, technical modifications, infrastructure investment, revision of rules and standards, operational changes, etc.

The risk information in the Safety Risk Model is also used to support:

- The development of Duty Holders’ safety priorities and plans – which are summarised every five years in the industry Strategic Safety Plan

- Prioritisation of areas for research – where to have the greatest impact on safety

- Transport operator risk assessments – as required by the UK regulations

- Identification of issues for audit and safety monitoring.

In order to help GB rail operators undertake their risk assessments as required by UK law, RSSB has developed a Safety Risk Model Templates Tool to enable users to produce a risk profile of their own specific railway operation, ensuring easy, reliable and consistent interpretation of the model risk data. The tool allows users to input their own information in order to modify the national risk profile to reflect their individual operating conditions.

Output and uses of the Safety Risk Model

High Level Output Specification

The UK government Department for Transport (DfT) has defined a High Level Output Specification (HLOS) for the GB railway industry. This describes improvements in safety, reliability and capacity expected during the funding period from April 2009 to March 2014. The improvements specified for safety are quoted in terms of a reduction of 3% in the national level of risk for both passengers and workforce. The DfT and the GB Safety Regulator, the Office of Rail Regulation, are using the Safety Risk Model as the primary means of measuring the performance of the industry against these safety metrics. This is because, for rare high-consequence events, the observed rate of occurrence of accidents over any given period does not provide a good measure of underlying safety risk.

Risk Monitoring – Annual Safety Performance Review

RSSB produces an Annual Safety Performance Report (ASPR) which contributes to the process of learning from operational experience, by providing decision-makers with wide-ranging analyses of safety performance and trends, and considering how key safety issues are being addressed by the industry. The Safety Risk Model forms an important input into this. The ASPR provides risk information to RSSB members, but is also intended to inform rail employees, passengers, the government and its agencies, and the public at large. Comparison with other European countries is also possible, indicating, for example, that current passenger and workforce fatality rates in Great Britain are well below the EU average.

Risk Assessment – ‘Taking Safe Decisions’

Safety decisions can be very complex. UK law requires duty holders to reduce safety risk to a level ‘as low as is reasonably practicable’ (ALARP). This involves making positive decisions about whether changes are needed to make things safer. ‘Taking Safe Decisions’ is a framework document published by RSSB on behalf of its members, the GB rail industry, and describes how the industry takes decisions that affect safety.

RSSB has developed an assessment tool, known as the ‘Taking Safe Decisions- Assessment Tool’ to help construct ‘Cost-Benefit Analysis’ assessments that are compatible with the good practice principles detailed in the framework. The tool provides a step-by-step approach, so assessors can use Safety Risk Model safety data correctly and consistently in their own detailed risk assessments.

Risk Assessment of Signals Passed at Danger

Safety Risk Model data also underpins a number of other assessment tools used regularly in the GB rail industry. One such tool is the Signal Passed at Danger (SPAD) Risk Ranking Tool, which is used to assess the potential risk associated with each SPAD event that takes place on the GB mainline network in a simple, quick and consistent manner. In this way, trends in SPAD risk – not just frequency – can be monitored, and efforts can be focussed on understanding SPAD events that pose a greater risk to the safe operation of the network.

Projects using the Safety Risk Model

Data from the SRM is regularly used in a number of research and development projects in the GB rail industry. One such project involved investigating the safety role of train windows in containing passengers during accidents, compared with their potential role as a means of escape after accidents. SRM data was used to examine the issue from first principles. The work concluded that it is better to have no windows provided explicitly for escape, and the industry has adopted this approach for all new vehicles.

In another example of how data from the Safety Risk Model has been used in understanding and quantifying various safety options, RSSB was commissioned to analyse the performance penalties and safety benefits associated with various scenarios in responding to emergency calls made from train cabs using the new train based radio system, GSM-R. Recommendations were made on which operational options should be implemented in order to maximise safety and performance benefits.

Future initiatives

A current project underway is to develop a suite of tools to use Safety Risk Model information to support the safety assessment of engineering change projects. This will bring improved efficiency and strengthen the risk assessment activities associated with these projects. By automating and standardising repeatable aspects of safety engineering processes, the approach is expected to save a large amount of time and effort associated with bespoke risk assessment work on new projects.

Another study is looking at improving the way in which leading and lagging indicators are applied in the GB rail industry. Customised risk information, as produced using the Safety Risk Model Templates, enables organisations to identify safety indicators to measure, as part of their safety management systems, that are most appropriate for their particular operations.

Conclusion

Although the Safety Risk Model is not the only risk management tool in the GB railway’s ‘safety management system’, it is a powerful tool which can be used to understand risk, focus resource and effort on areas of highest risk, thus making an important contribution to maintaining and improving safety on the GB mainline rail network. So far as we know, it is the only industry-wide risk model of its type in the world of railways. Indeed there is considerable interest through the RSSB website from nearly 900 people in 43 countries around the world and it has already been licensed to one significant European infrastructure manager.

References

1. See the Investigation into the Clapham Junction Railway Accident by Anthony Hidden QC.

2. See The Public Inquiry Into the Piper Alpha Disaster by the Right Hon. Lord Cullen.

3. See The Ladbroke Grove Rail Inquiry by the Right Hon. Lord Cullen.

4. Fault and event trees are a mathematical modelling technique using graphical representation of logical relations between a particular accident, its consequences and the causes or “precursors” of the events.

5. FWI is an overall measure of safety harm on GB railways, taking account of injuries and fatalities in the following way: One FWI = one fatality = 10 major injuries = 200 reportable minor injuries (or major shock/traumas) = 1,000 non-reportable minor injuries (or minor shock/traumas).

About the Author

Ben Gilmartin

As a chartered engineer, Ben Gilmartin has been engaged in safety and risk assessment work in several industry sectors including railways, petrochemical and maritime, where he has been involved in the application of risk management techniques such as QRA, CBA, HAZOP/HAZID and the UK Yellow Book. He is Chairman of the UK Safety and Reliability Society London branch.