Neopul’s dedicated work in Ireland

Posted: 3 December 2008 | | No comments yet

Details of how Neopul is actively working on some important projects in Ireland which include the Laois Traincare Depot, the LUAS Red Cow Rail Diversion and the LUAS B1-400 extension.

Details of how Neopul is actively working on some important projects in Ireland which include the Laois Traincare Depot, the LUAS Red Cow Rail Diversion and the LUAS B1-400 extension.

Neopul is actively working on some important projects in Ireland which include the Laois Traincare Depot, the LUAS Red Cow Rail Diversion and the LUAS B1-400 extension.

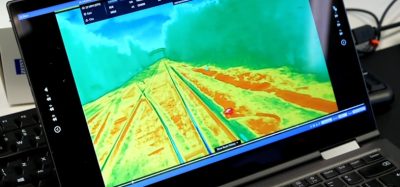

Laois Traincare Depot – (finished project)

The Laois Traincare Depot is a dedicated facility for the maintenance of Irish Rail’s new “Class 2200” Diesel Motor Units (DMU). The facility is located 2.5km from Portlaoise city centre and adjacent to the Dublin to Cork line which ensures the continuation of Portlaoise as an important regional railway centre.

The Depot has all the necessary facilities and the most up-to-date equipments for train maintenance.

The development consists of the following key elements:

- Permanent way

- Main Service Building

- Service and Valeting Slab

- Train Wash facility with Service Building

- Wheel Lathe facility within Wheel Lathe building

Neopul’s scope included the design, supply, installation and commissioning of the Permanent way within the depot. Neopul was also responsible for the design, supply, installation and commissioning of a modern Depot Personnel Protection System.

The Permanent way works included the installation of 13 new ballasted tracks on monoblock concrete sleepers fitted with “e-clip” Pandrol fastenings as well as 15 S8 geometry Switch and Crossings (S&C). These provide access to the Main Service Building incorporating one heavy and three light maintenance roads, the Service/Valeting Slab, Train Wash, six Stabling Roads, Chassis Wash Pits and a Wheel Lathe Building. The Permanent way track is constructed with new 18m UIC54 rails. The Service/Valeting Slab included two tracks directly fixed to the concrete base by Vossloh 336 rail fastenings. The light maintenance roads within the Main Service Building and the road over the Chassis Wash pit are raised on tubular steel pedestals. The other slab tracks are all embedded in concrete (track-in-slab) encapsulated by antivibration rubber. The track-in-slab has been installed using special Gauge System Frames (GSF) designed to guarantee track alignment and level as well as the track geometry parameters as gauge (1,600mm) and twist (1:20 or vertical). All the tracks end on the west side of the depot with Fixed Buffer Stops.

Another important feature of the Depot is the Depot Protection System (DPS) which is required to facilitate the safe passage of trains in and out of the maintenance sheds whilst ensuring there are no staff in the vicinity.

The DPS is formed by warning devices as high level beacons and Klaxons, by Powered Derailers installed on the roads accessing the sheds, Road Panels and Inbound/Outbound signals. The system is controlled by Electronic Datakeys pre-programmed with personnel details.

Track and OCS works on the LUAS Red Cow Rail Diversion – (finished project)

The ring motorway around Dublin has become crowded with traffic, so the decision was taken to widen the motorway from two to three lanes in each direction, and where possible to four lanes for exit roads. The interchanges are being changed from roundabouts to free flow grade separated interchange connections.

At the N7 interchange (Red Cow) the LUAS tram system was running through the roundabout and conflicting with the road traffic in three places, so this had to be changed as well.

A re-alignment for the LUAS line to separate the tram system from the road traffic at the N7 Interchange has been decided and Neopul was called to perform the track and OCS works.

Track works

These works included 700 meters of twin track from Nass Road to Red Cow through the M50/N7 Interchange. In this stretch, the line crosses the motorway four times. The track consists of approximately:

- 410m plinth track on slab and on bridges

- 145m embedded track on slab in paved areas and shared highway

- 132m ballast track

The track slab (plinth track) is constructed from 200mm reinforced concrete with a sub base of 150mm of compacted cement treated crushed rock. The track is to be constructed with a track gauge of 1,435mm and with the railhead inclined at an angle of 1:40 towards the track centre. All standard rails are of type S49 and grooved rail of type Ri 59. Transition slabs were provided between different track forms and a special solution was developed where the line crosses a main gas line.

OCS works

The traction power for the trams is supplied at a nominal voltage of 750V DC from transformer/rectifier substations distributed along the line and the OCS is designed to this voltage.

The OCS works included all temporary works required for safe construction of the system in an operational environment, including any necessary temporary features at tie in at Red Cow Stop and at Naas Road.

All the new OCS poles were erected clear of the operational tramway, or in non-traffic hours, together with stringing through of the new contact wire and removal of redundant poles, etc, near to the new route.

Redundant elements were carefully removed after main possessions, and delivered to a storage area required by the RPA.

Track and OCS works – LUAS B1-400 (project in progress)

The LUAS B1-400 contract is an extension of the existing tram green line which presently connects the city centre to the Sandyford Depot and includes the design, construction, testing and commissioning of the Luas Line B1 extension from this Depot towards Cherrywood.

It is Neopul’s job on this contract to design, supply and install the following:

- Approximately 7.5 kilometres of double-track connecting the existing LUAS terminus at Sandyford with a proposed terminus at Brides Glen

- Modification to the existing track system (and tram stop) at the Sandyford terminus

- Two trailing non-motorised switches and a track crossover located between the running lines in the vicinity of The Gallops tram stop for emergency and occasional operational use

- A set of scissor points in advance of the Brides Glen terminus comprising one set of motorised facing switches in the outbound direction, and three sets of non-motorised points set for spring operation to facilitate normal reversing operations at the stop

- Additional sidings and turnouts to stable 23 40m-long tramcars including all necessary works to support their operation at the existing Sandyford Depot, including turnouts, drives, tram arresting devices, access walkways and service bollards

- New OCS inside Sandyford Depot and do all necessary changes do integrate the old and the new OCS system

- Approximately 7.5 kilometres of OCS including Poles, suspensions (GRP bracketarms), anchoring, section insulators and contact wire

- Feeder cables and return traction along 7.5 kilometers of double track, including Trackside Distribution Cabinets and Track Disconnector Switches

Besides this, it is a requirement of the contract that these new works ensure a perfect interface with the existing LUAS system including the following:

- Compatibility, interoperability and through tram services with existing LUAS infrastructure

- All signalling and telecommunications systems shall be compatible with existing LUAS infrastructure

- Modification to the existing LUAS track system (and tram stop) at the Sandyford terminus

- Maintenance requirements

- Meet the Employer’s Requirements for noise and vibration limits

- Provide an adequate electrical insulation system to minimise the leakage of electrical currents to earth in accordance with the Stray Current Earthing and Bonding Requirements

- All OCS design and installation was made with the requirements for a further upgrade to 1500Vcc

Neopul will also provide Training to the operator personnel on the new system and will supply spare parts in accordance with RPA requirements.

Global Railway Review Autumn/ Winter Issue 2025

Welcome to 2025’s Autumn/ Winter issue of Global Railway Review!

The dynamism of our sector has never been more apparent, driven by technological leaps, evolving societal demands, and an urgent global imperative for sustainable solutions.

>>> Read the issue in full now! <<<