Customised Air Spring Systems for rail vehicles

Posted: 31 May 2010 | | No comments yet

Innovative suspension technology for modern rail vehicles for urban, mainline, or high-speed rail services; this is what ContiTech Railway Engineering is all about…

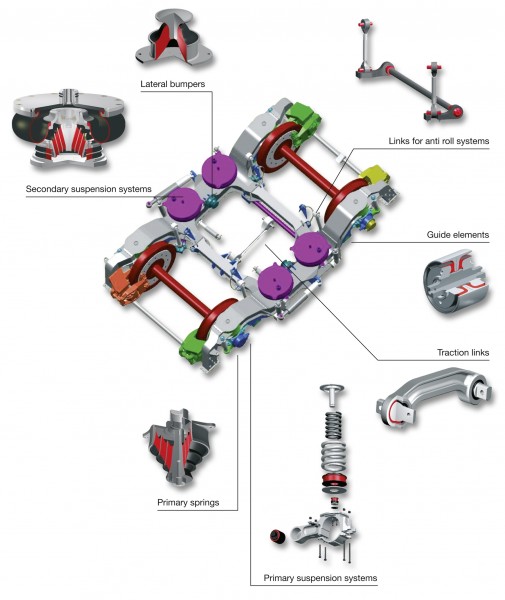

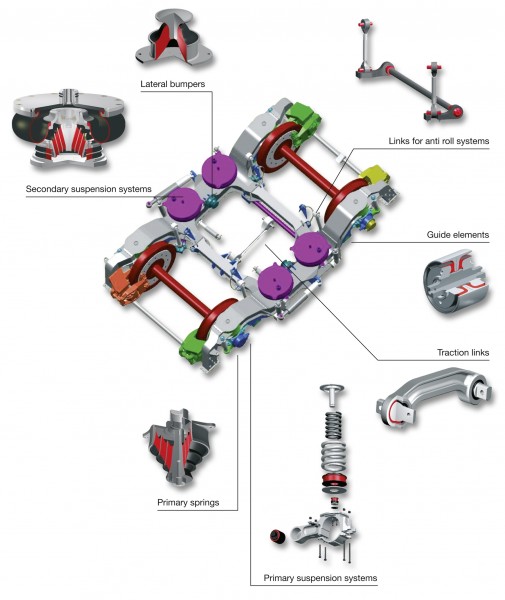

As a development partner and OEM, the segment of ContiTech Air Spring Systems in Hannover, develops complete suspension concepts and system solutions for primary and secondary suspension systems.

Thanks to high quality materials and material combinations, it is possible to fulfill the highest requirements regarding safety, comfort, speed and reduction in vehicle noise levels, as well as economic efficiency in goods and passenger vehicles.

As secondary suspension, air spring systems of the ContiTech and Phoenix brands decouple the bogie from the car body, and, at the same time, allow the bogie to turn as the train negotiates bends. In primary suspensions between the wheelsets and the bogie, systems and components from ContiTech guide the wheelsets and suspend the bogie. They minimise the impact of wheel-rail contact forces by damping vibrations and reducing structureborne noise. Innovative technology, like the GIGABOX, an entirely new type of system consisting of wheelset bearings and hydraulic spring, not only reduces freight train noise and relieves railway track stress, but increases service intervals as well. Consequently, air suspension technology from ContiTech gives train passengers a more comfortable ride and, at the same time, reduces the noise pollution from rail vehicles. Thus ContiTech plays a key role in making rail travel more attractive and in protecting the environment.

Complete systems and components from ContiTech for self-adjusting and non-selfadjusting air suspension in rail vehicles are used throughout the world in urban and mainline railways, freight trains, high-speed trains and magnetic levitation trains. Photo Credit: ContiTech

ContiTech has more than 50 years’ experience in the development and production of elastomer components. The service life of the product also profits from this experience edge. Localised positions subject to greatest damage are optimised in the design phase. The results of the complex lifetime analysis make it possible: With the help of the finite element method (FEM), the mechanical behaviour of a product is analysed at the concept phase, whether for a metal or elastomer component. The Air Spring Addi Vol calculation programme, which was developed specifically for this purpose, determines the influence of certain parameters such as geometric performance values, influence of the throttle, auxiliary reservoirs, amplitude or frequency on stiffness and loss angle. The input parameters – effective surface, change of the effective surface and the volume as a function of the spring deflection, isentropic exponent and tubing values – are determined with in-house software or the FEM. Comprehensive tests are conducted to verify and validate the results. Multi-body simulations or the multi-axial test stand with tempering chamber are further stations of research and testing which enable the provision of a full range of engineering and project management services. Many years of product-process competency, as well as the use of latest safety technologies, guarantee that the customer always gets technology in original equipment quality. The customised processes not only make it possible to perfectly harmonise products, but also substantially reduce development costs and times.

Suspension elements from ContiTech are used in prestigious high-speed projects such as the AVE (Spain), KTX2 (South Korea), CRH 1 and CRH 3 (China) and CRTL – the high-speed train between London and the Eurotunnel. However, the company is also represented with its products in urban traffic – in the new metro systems Shanghai, India, Korea, Europe and South America.