The development of high-speed railways in China and its impact on the Chinese economy

Posted: 5 April 2010 | | No comments yet

The Chinese railway dates back approximately 130 years. The first railway line, Wu-Song, was built in 1876 in Shanghai with a length of 14.5km and a track gauge of 762mm. The first railway built by Chinese engineers is the Jingzhang-Railway (Beijing to Zhangjiakou), finished between 1905 and 1909 with a total length of 201.1km, a small curve radius of 182.5m and four tunnels with a length of 1.6km. The Chief Engineer, Zhan Tianyou, who used a switchback to overcome a steep gradient, is called the father of China’s railway due to his achievement in construction of this railway line. Since that time, the Chinese railway has written its own story. At the beginning of the modern era, 21,810km of railway lines were in operation. Due to the economic reforms up until the late 1980s, the Chinese railway begun to grow significantly to meet the requirements of the growing economy and population. Over the last decade, the topic of high-speed railway has become a very important one for the Chinese railway industry.

The Chinese railway dates back approximately 130 years. The first railway line, Wu-Song, was built in 1876 in Shanghai with a length of 14.5km and a track gauge of 762mm. The first railway built by Chinese engineers is the Jingzhang-Railway (Beijing to Zhangjiakou), finished between 1905 and 1909 with a total length of 201.1km, a small curve radius of 182.5m and four tunnels with a length of 1.6km. The Chief Engineer, Zhan Tianyou, who used a switchback to overcome a steep gradient, is called the father of China’s railway due to his achievement in construction of this railway line. Since that time, the Chinese railway has written its own story. At the beginning of the modern era, 21,810km of railway lines were in operation. Due to the economic reforms up until the late 1980s, the Chinese railway begun to grow significantly to meet the requirements of the growing economy and population. Over the last decade, the topic of high-speed railway has become a very important one for the Chinese railway industry.

The Chinese railway dates back approximately 130 years. The first railway line, Wu-Song, was built in 1876 in Shanghai with a length of 14.5km and a track gauge of 762mm. The first railway built by Chinese engineers is the Jingzhang-Railway (Beijing to Zhangjiakou), finished between 1905 and 1909 with a total length of 201.1km, a small curve radius of 182.5m and four tunnels with a length of 1.6km. The Chief Engineer, Zhan Tianyou, who used a switchback to overcome a steep gradient, is called the father of China’s railway due to his achievement in construction of this railway line. Since that time, the Chinese railway has written its own story. At the beginning of the modern era, 21,810km of railway lines were in operation. Due to the economic reforms up until the late 1980s, the Chinese railway begun to grow significantly to meet the requirements of the growing economy and population. Over the last decade, the topic of high-speed railway has become a very important one for the Chinese railway industry.

The development of high-speed railways up to 2006

The six national speed-ups on conventional railways

From April 1997 to April 2007, the Chinese existing railway lines were totally upgraded six times. This speed-up was mainly achieved by updating the current conventional railways and operation of the newly produced trains. The first and second upgrades were carried out between April 1997 and October 1998, during which three North-South Corridors (Beijing- Guangzhou, Beijing-Shanghai and Beijing- Haierbing) were upgraded to a maximum speed of 140km/h. The personal transport capacity was increased from 2,070,000 people per day to 2,360,000 people per day. After the fourth upgrade phase, approximately 10,000km of railways were increased for a maximum speed of up to 140km/h. The latest speed upgrade phase started in April 2007, after which more than 16,000km of rails were upgraded to 120km/h (including 8,000km for a maximum speed of 200km/h).

The first newly built high-speed railway line in China

The development of the PDL (Personal Dedicated Line) started in the 1990s with the goal to strengthen the passenger transportation among the main cities in China. The slab track systems, due to its possibility for high-speed operation and high availability, became more-and-more the centre of attention for the PDL constructions. However, the application of slab track in China was limited on bridges or in tunnels with short length until 2006. Just three types of slab track systems were considered for practical application: the prefabricated slab system, monolithic system (classic ‘Rheda’) and elastically mounted bi-block sleeper system. The first time to operate slab tracks on long bridges was in 1999 on the Qin-Shen railway line (PDL between Qinhuangdao-Shenyang, see Figure 1). This line was opened in 2003 with a total length of 404km. It is an electrified dual-track railway designed for a top speed of 200km/h and the first newly built high-speed railway line in China. By 2007, its top speed was increased to 250km/h and will be further upgraded to 300km/h4. Failures, such as loose fasteners and the cracking of the asphalt concrete mortar layer were found during the operation. During the extension of this PDL line in 2003, optimisations were made to reduce these failures. However, there was still no experience to build slab tracks on earthworks. To be able to build uninterrupted slab tracks, Chinese railway engineers carried out a lot of research.

The first high-speed railway test line with uninterrupted slab track

The first test line with uninterrupted slab track is the Sui-Yu test line (see Figure 2) which was finished in 2006. This section has a design speed of 200km/h for passenger trains and 140km/h for freight trains. Six types of slab tracks were built here with a total length of 13,157km3. They are: prefabricated slabs (not coupled), prefabricated slabs with elastic matting, prefabricated frame slabs (not coupled), Prefabricated slabs with longitudinal coupling, double-block concrete sleepers and prestressed monoblock sleepers1. In this pilot project, not only the operation of these six types of slab track systems and different types of turnouts on earthworks were realised, but also the implementation of slab tracks on bridges with a span of more than 80 meters.

Experiences for the construction and installation of track systems and turnouts, methods for the inspection and measuring during the operation, were gathered. The MOR (Ministry Of Railway) described this project as an important milestone in the history of China’s railway construction. Measurements and investigations during the operation were carried out. The results were shown in1.

The latest development of high-speed railway lines up to 2009

Due to the numerous adaptations, which were made for the situational constraints, a longterm investigation is needed to evaluate and optimise the adaptations. However, the construction of PDL was planned to be finished in 2020 according to the ‘long-term railway network plan’, revised in October 2008 by the MOR. Till that time, all the eight Corridors (see Figure 3 on page 54) with a total length of 16,000km shall be finished, which belongs to the biggest high-speed railway network of the world. The strategy of ‘learning by building’, which was practiced in Germany and Japan for more than 40 years, does not meet the schedule of this large scale network.

The Chinese Railway Track System – CRTS I, CRTS II

From 2005 onwards, to accelerate the construction of PDL, slab track technology and know-how were transferred from Germany and Japan by the Chinese MOR, where, the slab track technology already has its long-term experiences. Four slab track systems with two base forms (prefabricated slab tracks and bi-block sleeper tracks) were transferred. And based on those, two Chinese railway track types, the CRTS I and CRTS II, were born. The CRTS I slab track system was transferred from the Japanese prefabricated slab track system; the CRTS I bi-block sleeper track system was transferred from ‘Rheda 2000’ (Germany). The CRTS II slab track system was transferred from the prefabricated slabs from Max Bögl (Germany); the CRTS II double-block concrete sleeper system was transferred from ‘Züblin’ (Germany). Table 1 shows the application examples of the CRTS I and II up until the end of 2009. At the time of writing this article, the Zheng-Xi PDL (PDL between Zhengzhou and Xian) and the Wu-Guang PDL (PDL between Wuhan and Guangzhou) were already put into operation.

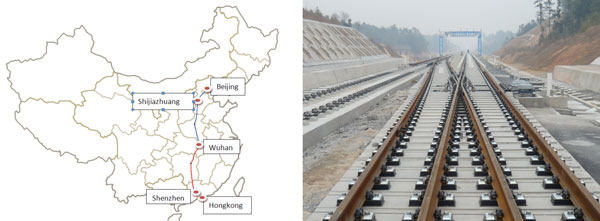

During the test run of the CRH (China Railway High-Speed) train on the Wu-Guang PDL, a speed record of 385km/h was achieved. This is also the longest high-speed railway in the world with a length of 968km, which belongs to one of the four sections of the Jingguang-Corridor (see Figure 4 on page 54) between Beijing and Hong Kong. The other three sections of this corridor are now under construction, including the section of Shijiazhuang-Wuhan with a length of 838km, the section of Guangzhou-Shenzhen with a length of 26km, and the section of Beijing- Shijiazhuang with a length of 281km. The design speed of this Corridor for all the four sections is 350km/h. According to the ‘long longterm railway network plan’, this corridor shall be finished before 2014 with a total length of 2,113km. After its construction, the total travel time from Beijing to Hong Kong will be less than 10 hours. Besides, the Wu-Guang PDL is the first large scale slab track railway line in China. Thus the accessibility between south and north China will be significantly improved.

The new Chinese Railway Track System – CRTS III

Based on the transferred technologies and the experiments gathered by construction of the Sui-Yu line and Wu-Guang PDL, the MOR asked for a so-called re-innovation investigation programme for ballastless track, which began at the beginning of 2007. This investigation has the goal to improve the design theory, the manufacturing technology, the construction equipment, installing technology and maintenance technology. Slab track systems, which can meet the Chinese situational constrains and energy saving at the same time, shall be developed. Also the construction materials, for example the emulsified asphalt and the cement asphalt mortar, are becoming a focal point for this investigation. One of the research projects of this investigation programme is the Cheng-Guan intercity railway line between Chengdu and Dujiangyan with a design speed of 200km/h. A new slab track system, the CRTS III, is put forward and taken into operation. The CRTS III was developed during 2007 and 2009 and has following characteristics:

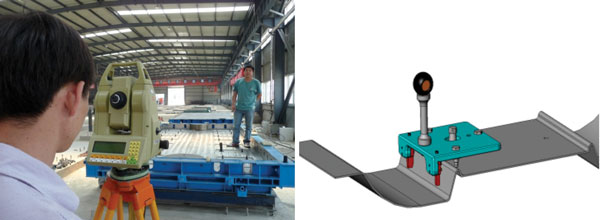

1. Other than the transformed slab track systems, the manufacturing of CRTS III is more individual. With help of special form boards, the position of rail seats is adjustable in both lateral and vertical directions (see Figure 5 ). Also superelevation and curves can be set during the manufacturing. The adjustment of the form boards is supported by a special computer program, which can calculate the exact position of the rail seats. The fine adjustment can be realised by the fastening system WJ-8C used in this system to ensure the rail evenness additionally.

2. No connection of slabs on bridges: The superstructure and substructure is separated by a sliding layer comprised of two layers of geo-textile and a waterproofed film. The purpose of this layer is to keep the expanding and contraction of the slabs without constraint from substructure. Another point is to make the maintenance and repair work easier.

3. Longitudinal coupling of slabs on earthwork and in tunnels: The slab track is connected in the longitudinal direction to improve the drive comfort and reduce the dynamic effect.

4. The CRTS III is a pre-stressed slab track system. The new slabs are built with a total length of 49.8km, including 14.3km on earthwork, 29.2km on bridges and 6.3km in tunnels (see Figure 6 ). This intercity line is planned to be put into operation on 1 May 2010. The differences between CRTS I, CRTS II and CRTS III are summarised and listed in Table 2.

The impact on the Chinese economy

From 1980 to 2005, China built 25,000km of new railway lines. This makes an increase of 1.67% per year. But in the latest decade, the Chinese GDP increases more than 9% per year. The railway development has not been sufficient compared to the economic development. Statistically, up to 2005, the average Chinese person takes the railway less than once per year. Still, due to the huge total population and rash increase of the population in big cities, the immobility and accessibility become the most important scale for the development of a location. On the other hand, up to 2005, the railway could only handle one third of the transportation of trading goods. Two thirds of the goods have to be transported using other mediums, for example shipping and road transport, which cause a much higher air pollution than railway transport. Some corridors are heavily used by goods trains and passenger trains, especially on the Nord-West- Corridor, which belongs to the main transport route for coal. The coal production is faster than the transport because of the regular traffic jams on main stations and crossing points of major routes. Also, the technical standard is by far too low. Within the 75,000km of existing tracks up to 2005, only 25,000km are double-lines and only 20,000km of tracks were equipped with electricity up to 2005. All-in-all, although the Chinese railway has driven 6% of the whole world’s driven railway kilometers, and has transported one quarter of the whole world’s railway load, the existing railways are not enough by far.

To increase the railway transport capacity, the MOR made a plan for railway development in 2004 that envisioned having 125,000km of railway lines by 2020, including 16,000km of PDL. The percentage of double-lines and electrically equipped lines shall be no less than 50%. With this development, the Chinese government expects that four billion people and four billion tonnes of goods can be transported per year. This equals an increase of 8% for passenger transportation and 4% of goods transportation annually from 2004 onwards. Especially with the separate passenger transport on the PDL network, the goods transport will be much more sufficient. At the same time, this separate operation pushes the economic development of west China due to the more cost-effective access to the nature resources of that region. China still mainly relies on coal for energy, but the coal mines are in different regions of the country where could be very far away from the industrial areas. The increase of capacity of goods transport will reduce the road transport and shipping, which also reduces the air pollution and energy consumption. In another aspect, due to the faster development on the east coast, there will be many people moving from west to east for work. The PDL network makes the communication between west and east much easier. At the same time, the general economic progress leads to a higher living standard which allows for more free time and therefore more possibility for travelling. Tourism will be pushed heavily due to the better accessibility. So, the development of the high-speed railway is a must for the economic development of China.

| Lines | Length [km] |

Design speed [km/h] |

slab track system | Construction start date |

Open date [5] |

| Jing-Jin Intercity line | 120 | 350 | CRTS II slab track system (transformation of Max Bögl) |

04/2005 | 08/2008 |

| Zheng-Xi PDL | 457 | 350 | CRTS II bi-block track system (transformation of Züblin) |

09/2005 | 02/2010 |

| Wu-Guang PDL | 968 | 350 | CRTS I bi-block track system (transformation of Rheda ‘2000’) |

01/2005 | 09/2009 |

| Jing-Hu PDL | 1318 | 350 | CRTS I bi-block track system (transformation of Rheda ‘2000’) |

04/2008 | 03/2013 |

| Type of slab track | CRTS I | CRTS Ⅱ | CRTS Ⅲ |

| Rail | CN 60 | CN 60 | CN 60 |

| Fastening system | WJ—7 | Vossloh 300 | WJ—8 C |

| Slab dimension [mm] | 4962×2400×190 | 6450×2550×200 | 5350×2500×190 |

| The connection layer | Cement asphalt mortar (standard thickness 50mm) | Cement asphalt mortar (standard thickness 30mm) | Self-compacting concrete (standard thickness 100mm) |

| Longitudinal status of slabs | Not coupled | Longitudinally coupled | Longitudinal coupled on earthwork, but not coupled on bridge |

| The reasonable comprehensive cost | 5600.000 ~ 5800.000 Chinese yean / single km | 6300.000 ~ 6500.000 Chinese yean / single km | 4800.000 ~ 5000.000 Chinese yean / single km |

![fig1 Figure 1: The position of Qin-Shen PDL and the fabricated slabs-superstructure on the Guohe bridge of Qin-Shen PDL [4,1]](http://www.globalrailwayreview.com/wp-content/uploads/fig11.jpg)

![fig1 Figure 1: The position of Qin-Shen PDL and the fabricated slabs-superstructure on the Guohe bridge of Qin-Shen PDL [4,1]](http://www.globalrailwayreview.com/wp-content/uploads/fig11.jpg)

Figure 1: The position of Qin-Shen PDL and the fabricated slabs-superstructure on the Guohe bridge of Qin-Shen PDL {4,1}

References

1. J. Ren, B. Lechner. “The experimental slab track section of China´s new Suining-Chongqing railway line”. RTR (2008/3) pp 47-52

2. K. Wu, X. Xin. “Innovative Study and Practice on the Engineering Technologies of Ballastless Track on Suining-Chongqing Railway”. RTR (2006) Slab Track, pp 18-22

3. Y. Zhu. “Technical innovation and development for design of high speed railway track in China”. The International Conference of the High Speed Railway Engineering Design, Construction and Maintenance Technology (ICHRE). Southwest Jiaotong University, 2009. Chengdu, China

4. Wikipedia: Qinshen passenger railway. http://en.wikipedia.org/wiki/Qinshen_Passenger_Railway

5. Wikipedia: High-speed rail in China. http://en.wikipedia.org/wiki/High-speed_rail_in_China

6. Z. Qian. “Construction and maintenance techniques about green CRTS III slab track system”. The International Conference of the High Speed Railway Engineering Design, Construction and Maintenance Technology (ICHRE). Southwest Jiaotong University, 2009. Chengdu, China

About the authors

Dr.-Ing. Stephan Freudenstein

Univ.-Prof. Dr.-Ing. Stephan Freudenstein has a degree in civil engineering from the Technical University of Munich. From 1995 to 1997, he was employed by the construction company Heilit + Wörner Bau-AG of Munich. From 1997 to 2002, he was Scientific Assistant at the Chair of Road, Railway, and Airfield Construction at Technische Universität München. In 2001, he was awarded a doctorate for work on anchor fittings in concrete track slabs. Since 2002, he has been the General Manager of the Department of Engineering and Development at the company RAIL.ONE GmbH. Since 2008 he has been the Professor and Head of Chair and Institute of Road, Railway and Airfield Construction at Technischen Uni – versität München, Germany.

Jia Liu

After finishing studies in Civil Engineering at the Technical University of Munich (TUM) in 2007, Jia Liu works as a researcher at the Chair and Institute of Road, Railway and Airfield Construction of TUM. She continues her post-graduate education as doctoral student at the Faculty for Civil and Geodetic Engineering in TUM at the same time. Her resent research focuses on railroad infrastructure design, especially on slab track systems and ballasted track systems with high resilient elements.

JuanJuan Ren

JuanJuan Ren holds a bachelor of engineering degree with a concentration in Railroad Engineering from Southwest Jiaotong University (SWJTU, Chengdu, China) in 2004 and was accepted as a PhD candidate after one year’s master study. From March 2007 to June 2008, she studied at TUM in Germany as an exchange PhD student. She received a PhD degree in 2009 at Southwest Jiaotong University (SWJTU) and is engaged as a member of faculty (Assistant professor) there. Her research programme is focused on railroad infrastructure design, especially on slab track structure for high-speed railway.