Highly elastic tracks for ballast-type permanent ways

Posted: 5 April 2010 | | No comments yet

The speed of today’s trains and the number of different regional specifications are factors posing stiffer challenges on modern track construction. Vossloh Fastening Systems is addressing these trends by developing new rail fastening systems for ballast-type tracks.

The speed of today’s trains and the number of different regional specifications are factors posing stiffer challenges on modern track construction. Vossloh Fastening Systems is addressing these trends by developing new rail fastening systems for ballast-type tracks.

The speed of today’s trains and the number of different regional specifications are factors posing stiffer challenges on modern track construction. Vossloh Fastening Systems is addressing these trends by developing new rail fastening systems for ballast-type tracks.

The so-called W Systems have established themselves for concrete sleepers. They are suitable for high-speed, heavy-haul, and lightrail tracks; they are always completely insulated electrically and can be reset in terms of gauge and height. All the fastening elements can be preassembled in the factory. Another asset of these systems is the ease of rail replacement: simply by pushing the tension clamps back into their preassembly position.

The new W21 is suitable for use in all climatic zones. In the standard NT 700 for mainline tracks, this system with a structural rigidity of 60 kN/mm has the same elasticity as its predecessor, the W14, yet with the Skl 21 tension clamp, it features fatigue strength of 2.5mm and a spring deflection of 14mm, well above that of the Skl 14.

The W21 HS (High-Speed) can be fitted with a highly elastic intermediate pad which has a rigidity rating of only 40 kN/mm, and is therefore softer and allows the rail to sink lower. In order to retain this property in the long-term, Vossloh has tested the entire system according to EN 13 481, part 2, and EN 13 146 parts 1-8, as well as to supplementary rail industry standards. The W28 has been developed specifically for the Austrian market. The related Skl 28 tension clamp offers extreme performance characteristics: a toe load of 14 kN, a spring deflection of 16mm, and fatigue strength of 2.5mm. The force-deflection curve indicates the differences to Skl 14.

The W30 system has been engineered for the Russian market and temperatures of between -60°C and +50°C. Required here instead of the 9 kN customary in many countries is a creep resistance of 16.5 kN. This is a rating achieved with the new Skl 30 tension clamp that comes with a toe load of 12 kN, a spring deflection of 14mm, and fatigue strength of 2.2mm. This latter specification, which is lower compared with the Skl 21, was selected by Vossloh in order to limit material input and increase the clamp’s cost efficiency. Also, the angle guide plate of the W30 has been fitted with a second tilting protection.

The W30 HH (Heavy-Haul) system addresses the special requirements prevailing in the USA. Building on the W14 HH, Vossloh has come up with a patented system for heavy loads of up to 35 t. Besides the Skl 30 tension clamp, this has a rail pad with a rigidity of 400 kN/mm. Additionally, the angle guide plate has a trapezoidal shape in order to yield a larger contact surface for dissipating the lateral forces.

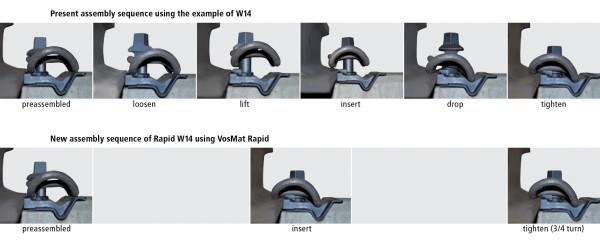

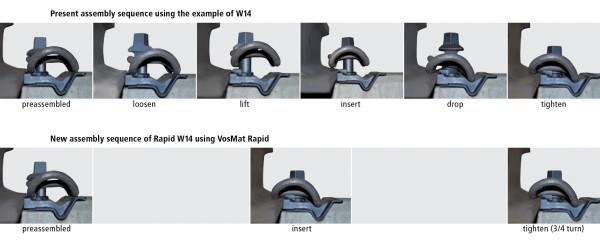

Vossloh’s Rapid W is a rail fastening system that reduces the assembly of W Systems from six to three steps and thus substantially raises the tracklaying and installation rates (see Figure 1). The preassembled tension clamps need only be inserted and tightened with a three-quarter turn. Height differences of up to 10mm between rail and concrete sleeper can be bridged. A precondition for using Rapid W is a compatible angle guide plate and the innovative VosMat Rapid tool. The system can be installed into the P95 track renewal train from Matisa.

Figure 1: Vossloh's Rapid W is a rail fastening system that reduces the steps needed to install W-Systems onto concrete sleepers from six to three

The KS 24 has been expressly developed in order to achieve higher elasticity on wooden sleepers. For the first time, the new Skl 24 tension clamp allows the use of intermediate pads with rigidity ratings starting from 40 kN/mm. Until now, only rigidities of over 200 kN/mm had been possible. Also, the geometry of the Skl 24 has been fine-tuned to typical track installation conditions. The middle bend is now so flat that it no longer obstructs horizontal bolts located where the rails are joined. The installation position is achieved when the middle bend of the tension clamp rests on the ribs of the ribbed plate.