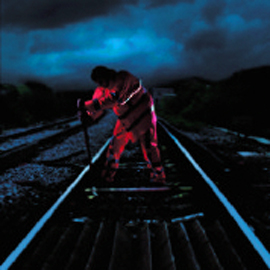

A journey of visibility: The evolution of rail safety

Posted: 29 November 2016 | | No comments yet

Stuart Jukes, managing director of Pulsar, provider of hi-vis workwear to the rail industry, shines a light on the hi-vis journey to enhance rail worker safety.

Stuart Jukes, Managing Director of Pulsar, provider of hi-vis workwear to the rail industry, shines a light on the hi-vis journey to enhance rail worker safety.

With 351 miles of track linking some of England’s largest cities, the HS2 project is at the forefront of rail innovation. Starting in 2017, the construction project is predicted to support over 100,000 jobs. The completion of the HS2 project and other ongoing work in the rail sector, including general maintenance and repair jobs1, are reliant on workers carrying out strenuous tasks, often throughout the night and in gruelling, wet conditions. As such, they must be equipped with effective and reliable safety equipment for all weathers. Quality high visibility clothing that incorporates retro reflective tapes, commonly known as hi-vis, forms part of this, and becomes more important than ever as the winter nights draw in. Where did hi-vis all start, and how should it be used today?

Where we’ve been

In the 1930s, brothers Bob and Joe Switzer developed ‘day-glo’ paint by mixing fluorescent minerals; quite a coup for the time2. The paint was initially used on movie posters, magic shows and stage shows before it was eventually noticed by the army as a means of reducing friendly fire deaths. The paint was then used throughout WWII to send signals from the ground to planes in the sky.

The first rail network to embrace hi-vis vests was the Scottish Rail Network in 1964. By 1965, all engineering and working staff on the newly electrified West Coast Main Line were issued hi-vis clothing after workers agreed it made their colleagues more visible.

In 2013, the EN471 European standard for high visibility clothing was replaced by EN ISO 20471:2013. This ensured the standard was applied internationally as opposed to being Euro-centric. The standard specified the minimum performance requirements and test methods for professional high visibility clothing, including colour and retro-reflection as well as the amount and placement of the hi-vis material on the protective clothing. The standard GO/RT 3279 regulates the supply of hi-vis clothing to the rail industry, particularly specifying that all clothing in this sector must be orange.

Where are we now?

If workers are within 3 metres (10 feet) of the track, they must wear orange, hi-vis safety garments that conform to GO/RT 32793. Railway tracks are often only closed when electrical work is being carried out on the lines. At all other times, railway repair workers and engineers will be notified of an oncoming train by a designated lookout who will wave a flag or blow a whistle. The close proximity of these workers to the trains makes it imperative that they are noticeable in all weathers and at all times of the day or night, hence the need to wear hi-vis clothing.

However the rules and regulations around certification for PPE are changing from April 2018. The previous PPE Directive focused on manufacturers placing products onto the market, but now the whole supply chain will be involved4. Importers, distributors and indeed anyone involved in the supply and distribution of PPE must take appropriate measures to ensure the product meets the appropriate standards, complying with the Regulation. It is vital therefore that the rail industry recognises these changes and acts accordingly, ensuring that workers are provided with hi-vis garments certified to the correct standards.

Where are we going?

Railway workers fully appreciate the importance of keeping themselves safe while they work and therefore the necessity to wear hi-vis garments. But wearing compliant, high performing garments is only part of the story. Providing high quality garments that are breathable and therefore comfortable to wear will guarantee the worker will respect it and more importantly, want to take care of it. Workers are also public facing representatives of the rail company they work for, so it is important for them to have a clean, unified corporate identity that will also boost morale and teamwork.

Selecting the right protective clothing can be a mine field and so here are the top three tips to help you choose the most suitable hi-vis clothing for your rail workers:

- Make sure the garments you are buying really do meet the appropriate standard and therefore ensure you have a copy of the EC Type Examination certificate with it. Without this, the garment cannot legally be worn, and this is an issue that is currently often overlooked by end users. You should not assume that your distributors have checked that the garment is compliant and suitable for your specific need.

- Look for garments that provide maximum conspicuity (visibility). The standards are clear and while some garments incorporate black or navy materials as these are less likely to show dirt, these are not allowed to be worn on or near the tracks.

- The biggest development in hi-vis has been in waterproofing and increased breathability. Rail workers should be comfortable in their workwear and be confident that it will protect them, both from hazards and the elements. If a worker is distracted by being too warm or getting wet, they could rush their job or not pay attention causing accidents, delays or problems for other workers. Innovative, high quality garments incorporate breathable fabrics that regulate body temperature and often garments have zipped-in layers to provide additional warmth in colder weather, further increasing the functionality of the clothing. Hi-vis has come a long way since the work of the Switzer brothers in the 1930s. As the rail industry continues to grow and develop, the safety precautions for the workers involved must evolve too. The need to make workers far more visible as well as incorporating key features, such as breathability, is paramount to ensure that workers can stay on track.

Stay Connected with Global Railway Review — Subscribe for Free!

Get exclusive access to the latest rail industry insights from Global Railway Review — all tailored to your interests.

✅ Expert-Led Webinars – Gain insights from global industry leaders

✅ Weekly News & Reports – Rail project updates, thought leadership, and exclusive interviews

✅ Partner Innovations – Discover cutting-edge rail technologies

✅ Print/Digital Magazine – Enjoy two in-depth issues per year, packed with expert content

Choose the updates that matter most to you. Sign up now to stay informed, inspired, and connected — all for free!

Thank you for being part of our community. Let’s keep shaping the future of rail together!