The role of DAC in optimising European rail freight: Challenges and opportunities

Posted: 15 April 2025 | Hugo Tabouret | No comments yet

Hugo Tabouret, Technical Affairs Manager at UNIFE, sat down with Global Railway Review’s Halimah Haque to discuss the potential of Digital Automatic Coupling and its impact on the future of European rail freight.

Digital Automatic Coupling (DAC) is a major technological leap for the rail freight sector. Can you explain how the DAC technology works and why it may be essential for improving operational efficiency in European rail freight?

At the moment, coupling and uncoupling wagons and locomotives is done manually. This process is not safe for workers and it prolongs train preparation time

Let’s start by explaining the current situation in the rail freight sector. At the moment, coupling and uncoupling wagons and locomotives is done manually. This process is not safe for workers, as they must stand between the cars, and it prolongs train preparation time, including break tests. Currently, there is limited connection between the wagon and the rest of the world, which makes it difficult to localise and keep track of goods within the network. This results in a competitive disadvantage for rail freight.

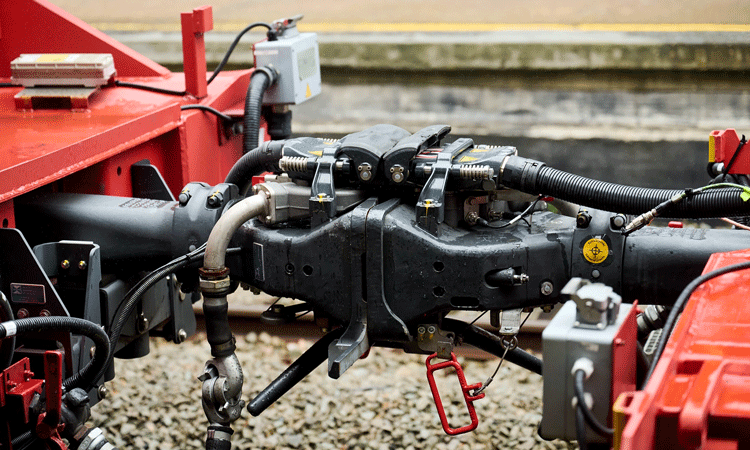

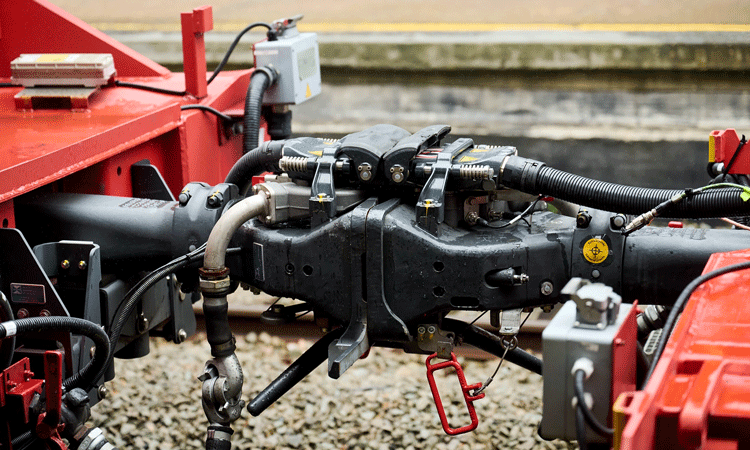

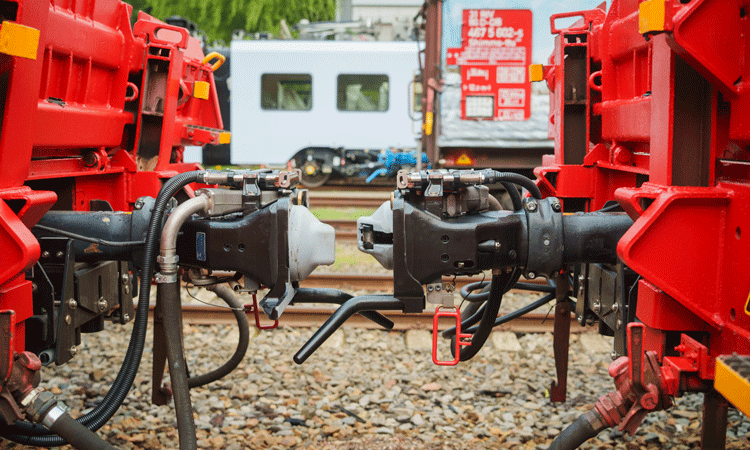

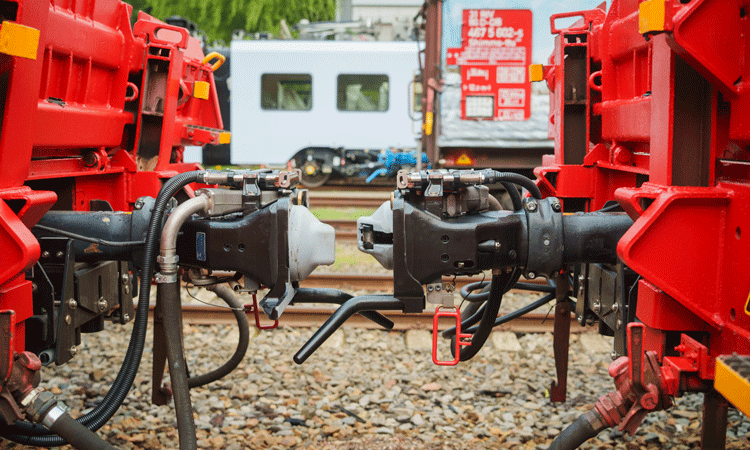

Moreover, Europe is one of the only regions in the world still relying on manual couplers – the U.S. has used automatic couplers since the 19th century, and China uses standardised automatic couplers as well. So, the goal of DAC is to integrate data and electricity into freight trains, allowing for automatic coupling and uncoupling under safe conditions. Essentially, DAC functions as a kind of hook that enables one wagon to automatically connect to another when they come together. Once they are pushed together and hooked automatically, there will be a power, pneumatic and data link that is established between the wagons. This capability opens the door to a wide range of digitalisation opportunities that the rail freight sector cannot benefit from at the moment.

Additionally, about 50% of freight trains in Europe operate across borders, making interoperability essential. This means that wagons must be compatible with any other freight locomotive in Europe, which is why DAC is co‑ordinated as a European project.

UNIFE plays a crucial role in co-ordinating efforts between the rail industry and EU authorities. How has your team been involved in the Europe’s Rail Joint Undertaking, and what are the key challenges in implementing DAC on a Europe-wide scale?

Thank you for this question, as it’s an important topic. I see three main categories of challenges. First, there are technological challenges. We are confident in overcoming these, because this is the role of the supply industry. Current technological challenges are addressed in projects led by EU-Rail, also known as ERJU (Europe’s Rail Joint Undertaking), which is funded by the European Commission and the sector.

UNIFE is participating in the European DAC Delivery Programme (EDDP) which is co-ordinating different European activities on DAC. Additionally, the technology itself is being developed in the Innovation Pillar, specifically the Flagship Project 5, also called “TRANS4M-R”, in which UNIFE members are actively contributing. We are also participating in the System Pillar for full digital freight train operations, known as the Task 4 of the System Pillar. One challenge we are currently addressing within this System Pillar Task is organising a central body at the EU level to manage the software updates for the DAC equipment. Once the freight wagons and locomotives are equipped with DAC, software will be embedded in the systems that must be regularly updated and remain interoperable between each other. We’ve got a good team of suppliers and railways working on this and we are confident about finding technical solutions as long as we secure the necessary financing.

Another category of challenges is the authorisation of DAC, particularly the re-authorisation of vehicles that will be retrofitted with the technology. This includes the wagons, but also the locomotives. Our goal is to ensure that the authorisation process for DAC is not too cumbersome. We aim to streamline this process to make it as efficient and smooth as possible for our members and the entire sector. We are working with the European Union Agency for Railways and rail stakeholders in a topical working group to achieve this.

Finally, the next steps and challenges for DAC involve the so-called pioneer DAC trains and migration topics. This pioneer DAC trains phase involves deploying up to 100 trains equipped with DAC technology. The purpose of this phase is to complete the last checks on the technology, but in commercial service. This will help troubleshoot any last issues for the technology. The rail operating community is organising this pioneer phase now.

From the rail supply industry’s perspective, we’ll need commitments and clarification regarding the planning for wider migration. If we are to invest in more manufacturing capacities, we need a clear understanding of the broader migration timeline. If we go into full migration, which we hope for, then we will have to massively equip Europe with the required technology, and the industry will have to invest in manufacturing capacities to meet this demand.

c: EDDP DACcord

Germany, Austria and Switzerland have expressed their support for DAC. What makes these nations enthusiastic about this technology and what political support is still needed from other EU members to ensure its success?

The countries you’ve mentioned are generally supportive of rail freight, but they are not the only ones. For instance, we’ve received positive signals from Norway, Belgium and the Netherlands as well. Germany, Switzerland and Austria, in particular, are countries where rail freight and industries are strong, and they recognise the importance of DAC for their economies and the wider European supply chain. These countries also understand the benefits that rail freight can play in decarbonising the economy and goods transport.

However, there is a need for alignment among most, if not all, EU Member States. There also needs to be strong political drive at the EU level, given that it’s a European-wide project. Indeed, as I’ve already mentioned, as DAC systems need to be interoperable across borders, the success requires both EU-level political drive and support from individual Member States.

In terms of technical standards and safety regulations, what considerations need to be made for a smooth and safe deployment of DAC across the European rail network and how is UNIFE contributing to these discussions?

Yes, some technical standards need to be created or adapted, and the Technical Specifications for Interoperability (TSIs) need to be adapted to accommodate DAC. These TSIs are a specific set of regulations for the rail sector, and their adaptation is already underway, especially in the next TSI revision package to be published in 2027, which the European Union Agency for Railways is currently working on. DAC is one of the priorities identified by the European Commission of this 2027 TSI revision package.

This work is also ongoing in the EU rail development projects that I mentioned earlier. UNIFE as a European representative body is closely monitoring the evolution of the regulatory framework and will be involved in updating the TSIs. We also monitor standard development linked to DAC through CEN-CENELEC technical committees and co-ordination groups.

DAC is often mentioned as a way to keep rail freight competitive with road and air transport. What benefits do you see DAC bringing to rail freight and how do you think it will impact the broader logistics sector?

Thank you for this important question. As mentioned earlier, freight wagons in Europe are currently manually coupled and uncoupled, which makes rail freight less competitive. DAC aims to bring electricity and data to freight trains, enabling digitalisation. DAC will serve as a facilitator for a wide range of digital applications.

DAC aims to bring electricity and data to freight trains, enabling digitalisation. DAC will serve as a facilitator for a wide range of digital applications.

For example, it will allow automatic break tests and automated train preparation, saving time and reducing costs for operators and wagon keepers. Additionally, DAC will introduce more telematics and monitoring applications, improving efficiency. A key benefit is the ability to enable moving blocks, formerly known as ETCS Level 3, which will significantly boost network capacity in Europe. We estimate that DAC could increase rail freight productivity by 15%, which is enormous at an EU level.

In addition, DAC will allow for longer and heavier freight trains, further increasing the capacity and competitiveness. The system’s monitoring functions will improve reliability, particularly through predictive maintenance. So, all these benefits will have a positive effect on modal shift, reducing emissions and energy consumption for goods transported in Europe. Also, DAC will contribute to achieving the EU’s sustainable and smart mobility targets and support the EU Green Deal targets as well.

c: EDDP DACcord

What advancements do you foresee in the integration of DAC with other digital systems, such as automated train operations and smart logistics platforms?

We need to view the rail network and the wider railway ecosystem as an integrated system. The full benefits of DAC will be realised when most freight trains are equipped with it, although some of these benefits may also be seen from the start of deployment. In order to fully harness its potential, widespread adoption of DAC is essential.

DAC will enable further digitalisation, allowing for automated train operations, especially automated shunting operations in marshalling yards. Yard automation will highly benefit from DAC-equipped freight trains. But one aspect to consider is that DAC will also facilitate ‘seamless rail freight,’ making it easier to integrate rail into the wider multimodal logistics chain.

DAC will also improve co-ordination between different transport modes, such as waterways and road, as well as enable more digitalised and automated operations across the multimodal network. For instance, DAC will provide more information on the estimated time of arrival for goods, allowing for better predictions, and optimisation of supply chain logistics.

What message would you like to convey to European policymakers about the importance of DAC for rail freight? Do you have a message for those who are opposed to DAC?

Much of this criticism focuses on the types of trains that would benefit from it…

While DAC will indeed benefit single wagon traffic, it will also benefit the block trains and combined transport traffic.

Yes, there is some criticism of DAC and the benefits it could bring to the rail freight sector in Europe. Much of this criticism focuses on the types of trains that would benefit from DAC, with some suggesting it will only benefit single wagon traffic. However, this is not correct. While DAC will indeed benefit single wagon traffic, it will also benefit the block trains and combined transport traffic.

This is because automatic break testing, automated train preparation and increased network capacity will not only benefit single wagon operators, but also other types of rail freight transport, as well as marshalling yard operators and infrastructure managers.

As for the message to decision-makers, the rail supply industry is very thankful to the European Commission and the Europe’s Rail Joint Undertaking for their support in the development of DAC technology. Initiatives like the System Pillar, or TRANS4M-R Project within the Innovation Pillar of ERJU and the European DAC Delivery Programme have enabled the setting up of a strategic approach for DAC’s development. The next step is the deployment of pioneer DAC train, which will demonstrate the system’s benefits and facilitate a co-ordinated European migration to DAC.

If we are serious about increasing the capacity of rail freight, to make rail more competitive and reduce the external cost of transport – such as emissions and road congestion – DAC is a key technical enabler. The rail supply industry is ready to provide DAC to the whole sector, but we need a clear commitment in terms of financing and a detailed plan for the technology’s deployment. This will allow us to meet future customer needs and scale up our capacity production.

Issue

Related topics

Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Freight, Interoperability & Liberalisation, Regulation & Legislation, Safety, Technology & Software