From coupling to innovation: How DAC enables the full digital freight train vision

Posted: 9 December 2024 | Andreas Haller - DB Cargo AG | No comments yet

Andreas Haller, Lead DAC Module Technology & Operation Intelligent Freight Train at DB Cargo, discusses the transformative potential of Digital Automatic Coupling (DAC) in revolutionising rail freight efficiency and interoperability across Europe.

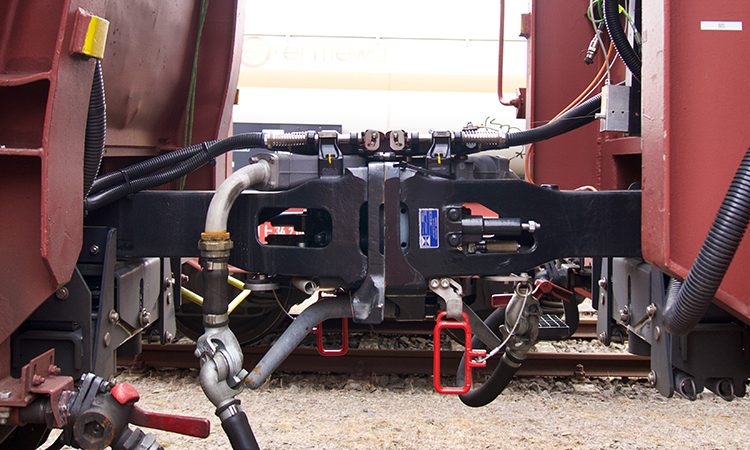

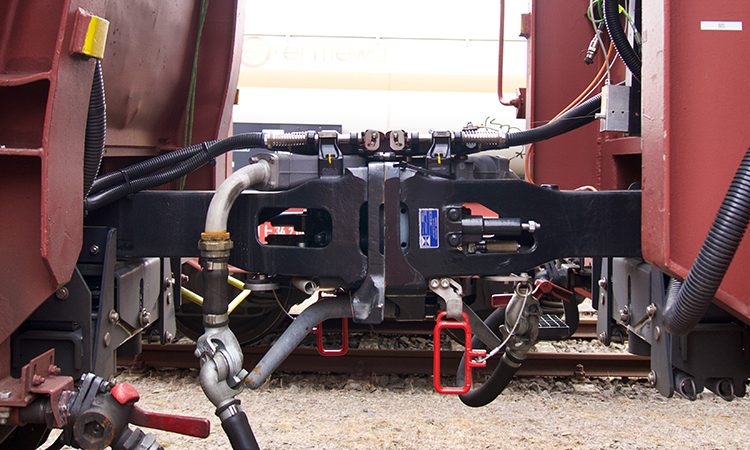

Credit: DB Cargo AG

How will the rail freight industry benefit from the Digital Automatic Coupling (DAC) and can you share specific ways it effects process efficiency?

Digital Automatic Coupling (DAC) is one of the key enablers for the Full Digital Freight Train… and will help overcome existing challenges”

Digital Automatic Coupling (DAC) is one of the key enablers for the Full Digital Freight Train (FDFT). This target system is the basis for future European freight train operations and will help overcome existing challenges for all stakeholders involved.

Today, the European rail freight sector still relies on vehicles with screw couplers; a solution from the 19th century, mostly eliminated in other parts of the world by now. This technical deadlock results in disadvantages like limited longitudinal forces and a high degree of manual activities.

DAC is going to improve operations in various respects:

- DAC withstands higher longitudinal forces than the screw coupler. This allows for heavier and longer trains, respecting infrastructure restrictions. Trains can run faster, as higher braking forces become possible

- DAC allows for continuous train integrity monitoring. This is a prerequisite for running freight trains on infrastructure sections equipped with ETCS of the highest technical level. This means that DAC helps increase the infrastructure efficiency as track-side track vacancy detection systems can be eliminated, thus fostering moving block operations

- Yard operations become more efficient. Decoupling and coupling of wagons are accelerated and mandatory train preparation processes like the brake test as well as the composition detection can be automated. Operations become quicker and less manual labour intensive, and more trains can be processed on the same tracks at the same time

- Wagons can be decoupled either remotely or from the wagon side, resulting in less exhaustive and more ergonomic workplaces for shunting staff.

When preparing rail freight for DAC operations across Europe, what was the first milestone achieved?

In Europe’s Rail project FP5-TRANS4M-R, the overall goal was to increase efficiency in rail freight logistics. The starting point for DAC was the harmonisation of operational procedures. Together with experts from the sector, the project managed to align and publish harmonised operational procedures for FDFT. This milestone was achieved in 2023. The result was shared with the sector in a webinar hosted by the UIC together with Europe’s Rail Joint Undertaking and the the European DAC Delivery Programme (EDDP). The operational procedures and the recording of the webinar can be found online.

Credit: DB Cargo – Preparing for DAC installation.

Compatibility is key for the success of DAC. How will a unified approach be implemented across rail systems in Europe?

Compatibility of interfaces is our focus since day one of the project. This is especially important for wagon keepers and railway undertakings”

Compatibility of interfaces is our focus since day one of the project. This is especially important for wagon keepers and railway undertakings. Compatibility includes hardware of couplers as well as the backend systems on the operator and infrastructure side.

Concerning hardware, key for the success of DAC, are the connections from coupling head to coupling head, as well as from the spring package to the coupling head, regardless of their suppliers. Our aim is to establish fleets which are not supplier specific, and manageable regarding warehousing costs.

In the FP5-TRANS4M-R project, more than 70 partners, including railway undertakings, infrastructure managers and industry partners, are working together to achieve compatibility. Through the collaboration with the European DAC Delivery Programme (EDDP) and jointly organised sounding boards, all stakeholders from the sector may contribute as well.

How does the sector manage alignment between the different stakeholders involved with the preparation for DAC?

The sharing of knowledge and the dissemination of results play a significant role when it comes to the preparation for the DAC”

With the number of stakeholders involved, managing sector alignment is an important task. The EDDP is at the centre of this activity. The objectives of the EDDP are to promote cooperation in the sector, ensure transparency and opportunities for participation and to prepare decisions, e.g. the selection of the design for the coupling head.

Moreover, all DAC-related projects, be it national or European, are working on a common goal. This is achieved because all those affected can get involved and obtain information. Therefore, the sharing of knowledge and the dissemination of results play a significant role when it comes to the preparation for the DAC. Not only now, but as an ongoing activity for the whole lifecycle of the preparatory phase.

Looking forward which transformation do you see in rail freight transport in the next decade?

Digitalisation and automation are the tools for transforming rail freight for the future”

Digitalisation and automation are the tools for transforming rail freight for the future. At DB Cargo, we are working on the target vision of the ‘Intelligent Rail Freight Transport System’. This vision includes FDFT and DAC. With our projects, we are contributing innovations along the entire value chain in the following seven fields of action:

- Integrated terminals and access to the system

- Automated first-mile service

- Automatic train formation and train splitting

- Efficient train operation on the mainline

- Full shipment and asset-transparency

- Smart resource-planning and -management

- Smart maintenance.

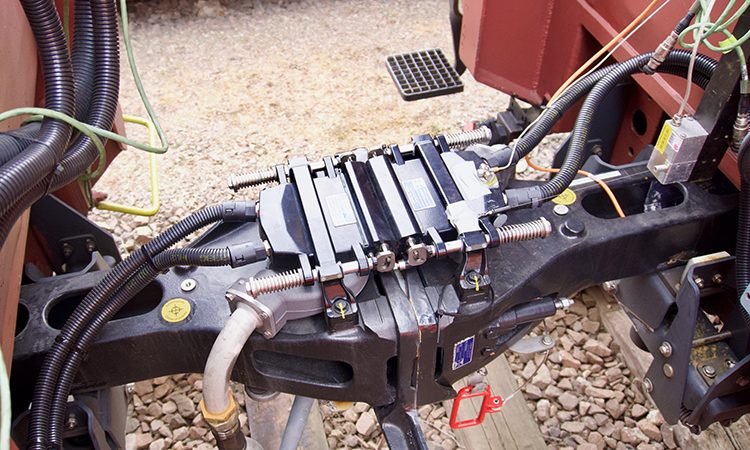

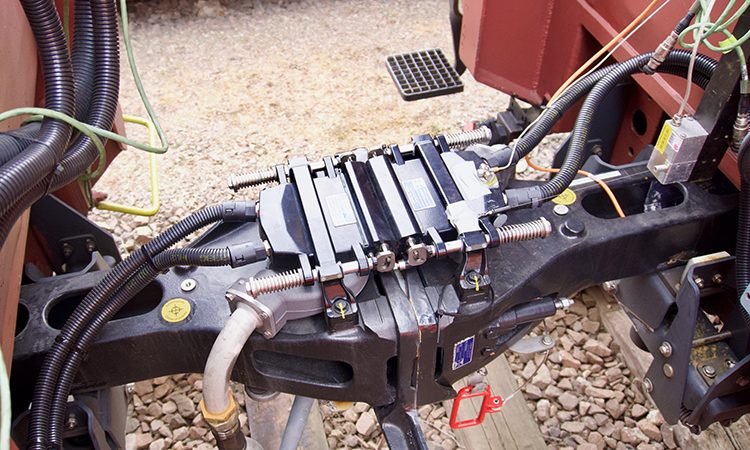

Credit: DB Cargo

Which new train functions will the Full Digital Freight Train offer and how does DAC enable these capabilities?

DAC enables automatic mechanical and pneumatic coupling and uncoupling of freight wagons and establishes a power and data connection for all freight wagons and locomotives in a train”

DAC enables automatic mechanical and pneumatic coupling and uncoupling of freight wagons and establishes a power and data connection for all freight wagons and locomotives in a train.

Today, a standard freight wagon neither has energy supply nor integrated data connection. There are several isolated applications and stand-alone solutions available, e.g. for basic GPS information. FDFT strives to unify solutions and create a single platform that can be upgraded, extended and enhanced in the future.

Designed as a platform for future developments, FDFT forms the basis for innovation. The first train functions to be developed are the ones included in the DAC Basic Package comprising:

- Harmonised DAC including mechanical, pneumatical, power and data connection

- Automatic coupling

- Decoupling triggered via communication network on the train push button or manually from the wagon side

- Prevent coupling for hump shunting

- Train composition detection

- Train length determination

- Train integrity monitoring

- Automated brake test.

Looking forward, FDFT allows the implementation of additional functionalities such as optimised braking systems, distributed power systems (DPS) and future innovations in rail freight transport.

Global Railway Review Autumn/ Winter Issue 2025

Welcome to 2025’s Autumn/ Winter issue of Global Railway Review!

The dynamism of our sector has never been more apparent, driven by technological leaps, evolving societal demands, and an urgent global imperative for sustainable solutions.

>>> Read the issue in full now! <<<

Related topics

Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Freight