A game changer for rail freight: How DAC is shaping Rail Logistics Europe’s future

Posted: 28 October 2024 | Jerome Ebrardt - Rail Logistics Europe | No comments yet

Jerome Ebrardt, Projects and Innovation Manager, Strategy & Development Direction at Rail Logistics Europe, spoke to Global Railway Review’s Halimah Haque about the transformative potential of Digital Automated Coupling (DAC) and its role in advancing innovation, efficiency and safety in the rail freight sector, while also addressing any reservations.

Given your role, how do you see DAC benefiting both Rail Logistics Europe and the wider rail freight sector?

We can consider DAC as an enabler of automation and digitalisation in rail freight train operations, improving efficiency, productivity and safety

I am the Projects and Innovation Manager, Strategy & Development direction at Rail Logistics Europe. My key focus is innovation. Digital Automatic Coupling (DAC) is a systemic project for the global rail freight sector, specifically at the European level. We can consider it as an enabler of automation and digitalisation in rail freight train operations, improving efficiency, productivity and safety through different functionalities. These include automatic coupling, automatic uncoupling from the locomotive and wagon sides, automatic train composition detection, train integrity checks and automated brake tests.

DAC will provide significant time savings in freight operations, particularly for train building in marshalling yards and for brake tests, which could be reduced by more than 50%. This will allow for increased capacity on tracks and in infrastructure, including marshalling yards and terminals, as well as customer private sidings, thanks to the shortened operation times. This is an important benefit, especially given the expected increase in rail traffic; the rail freight sector aims to double its traffic within Europe by 2030. So, to achieve this we really need technical enablers, and DAC is one of the main ones.

Another benefit DAC will bring is improved safety for RLE staff and operators. They will no longer need to go between the wagons to manually handle the current screw coupler, which weighs around 20kg, reducing the risk of getting injured. This is particularly important at a time when many rail companies in Europe face difficulties to hire new staff. While some jobs are not considered as attractive. the implementation of DAC can help mitigate this staff shortage issue.

Finally, the benefits expected from DAC implementation are valid for the whole sector, as well as RLE, without distinction between RLE and other stakeholders in the rail freight sector.

Can you please explain Rail Logistics Europe’s role in the European Trans4m-R project and how it supports your innovation goals?

The goal is to provide a better understanding of the costs and benefits of the DAC system and share this information with the European DAC Delivery Programme”

Yes, so RLE, which is part of SNCF Group, is an active member of the Trans4m-R project, a European project considered by Frederic Delorme, our CEO as one major project. He believes that we need some breakthroughs – game changers for the rail freight sector – and DAC development is one of these game changers.

RLE is providing funding and human resources to the project, bringing the expertise of our employees in several work packages. We are also leading one of the project’s work packages focused on the cost-benefit analysis for DAC. The goal is to provide a better understanding of the costs and benefits of the DAC system and share this information with the European DAC Delivery Programme (EDDP), which is responsible for the future deployment modalities at the European level.

To address the second part of your question, we at RLE clearly share the need for automation and digitalisation in rail freight operations. Like other rail freight stakeholders, we aim to increase our efficiency and attractiveness to customers. Given that profit margins in the rail freight industry are quite low, we carefully evaluate every innovation project that could enhance our competitiveness and efficiency, which is why we are actively participating in the Trans4m-R project.

What are some of the main challenges in checking the compatibility of Europe’s locomotive fleet with DAC and how is RLE handling them?

There are many different types of locomotives currently running in Europe, which is why we need to consider this topic at the early stage”

For freight wagons, the work is quite advanced regarding the necessary equipment installations. There is an existing UIC regulation that mandates all newly built wagons, including those built in past years, to have a designated space under the body of the wagon for future DAC installation. This eases part of the development work for the wagons, but this is not the case for locomotives, especially the existing ones. To install DAC on locomotives, an engineering study is needed to assess the compatibility of each locomotive type and the efforts that could be needed to retrofit the locomotive with DAC.

There are many different types of locomotives currently running in Europe, which is why we need to consider this topic at the early stage. At RLE, we are currently preparing a “light” engineering study for the main types of locomotives of our fleet. The aim is to evaluate the level of complexity and costs of retrofitting these locomotives with DAC. At this stage, we are focusing on getting a preliminary understanding of the complexity rather than conducting a full engineering study, which would be costly and time-consuming. This initial assessment will help us identify the locomotive types best suited for DAC installation, enabling us to start retrofitting these types first.

This question of locomotive compatibility with DAC Is very important for the Pioneer Trains phase, which is not so far. We want to identify the best locomotive types that will be easier to retrofit with DAC in the short-term future. We are fortunate to have a rolling stock engineering centre within SNCF, which has significant expertise in this area. We are collaborating with them on this light engineering study.

We believe this initiative could be extended more broadly in the future, potentially with the involvement of other European partners or countries. Another important point to consider is the need to establish DAC as a standard for new vehicles. European regulations or normalisation texts should ensure that manufacturers offer DAC-ready vehicles in the future, and we believe this is a crucial point to be considered.

As you prepare for the Pioneer Trains phase in 2026, what are the key steps RLE is taking to ensure its success?

The main goal for RLE, and all the stakeholders involved in the Pioneer Train phase, is to really check if our assumed benefits of DAC are achieved… This phase will be the first real-world test of DAC”

RLE is fully committed to the Pioneer Trains phase, which should begin by the end of 2026. This will be the first opportunity to test the DAC system on existing commercial traffic, involving all relevant stakeholders, including railway undertakings (RU), wagon keepers, customers and safety agencies. The rolling stock fitted with DAC will need to be authorised by the National Safety Agency as it will run on the main tracks with new equipment.

To be successful, we need to consider some key steps. First, we need to identify up to five relevant traffics and then get the approval of all the involved partners. As already mentioned, we are focusing on the locomotives currently used, particularly for those used in the pre-identified traffic for the Pioneer Train phase. Additionally, we want to work on it in an agile and flexible mode, responding quickly to developments as they arise.

I’d like to make a last point – the main goal for RLE, and all the stakeholders involved in the Pioneer Train phase, is to really check if our assumed benefits of DAC are achieved. This applies not only to us but also to other stakeholders, infrastructure managers and users and customers. This phase will be the first real-world test of DAC, and that’s why we are deeply committed to participating in it.

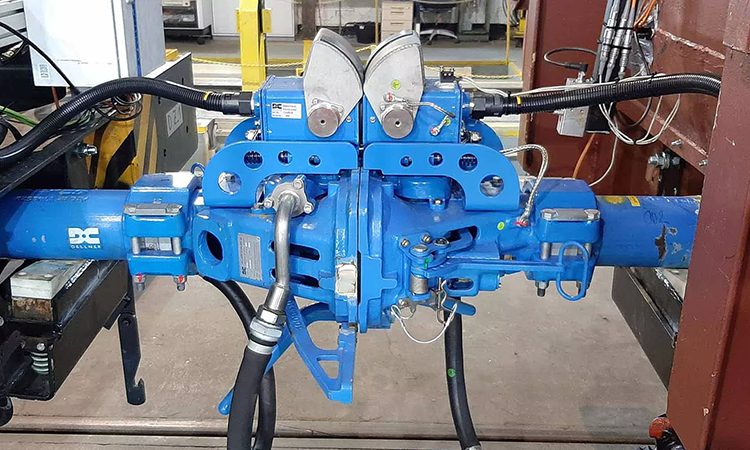

Credit: DB Cargo

How is RLE approaching the funding needed for DAC implementation, and what partnerships are involved?

Yes, DAC is a major transformation for the rail freight sector, and with that comes high costs. So, for sure, we need funding to move forward. We have already received financial support, particularly from the European Commission, through the Trans4m-R project under Europe’s Rail initiative.

There is a second stage of funding currently underway, with the European Commission planning to provide funding through the Connecting Europe Facility (CEF) call. This call was published at the end of September 2024, and we have until the end of January next year to submit our proposal. DAC is clearly included in this call, representing a positive step from the European Commission in recognising the need for further funding. However, this won’t cover all the activities required to launch the Pioneer Trains phase, so we will also need to explore national funding opportunities.

With other stakeholders of the Trans4m-R project and EDDP, we are currently working on forming a consortium to provide a common answer to the CEF call for funding, which will include the Pioneer Train project. This will help secure funding from the European Commission for this crucial phase.

Moving on, could you tell us a bit about the Monitor project and how it fits into RLE’s efforts to digitalise rail freight?

The Monitor project focuses on introducing functionalities such as automated brake testing, real-time brake control while the train is running and train composition management”

So, the Monitor project is another project aimed at bringing more automation and digitalisation to the rail freight sector. It complements the DAC project in many ways, but without the coupler itself. Instead, the Monitor project focuses on introducing functionalities such as automated brake testing, real-time brake control while the train is running and train composition management.

This national level project is being conducted alongside two other partners: Wabtec, an industry company also involved in the DAC project, and Régie des Transports de Marseille, a regional RU based in the Marseille area. In collaboration with these two partners, we aim to test the Monitor project’s functionalities by 2026, including the digital brake test, detection of online brake anomalies, vibration monitoring and automated train composition and integrity checks.

While Monitor and DAC are complementary, Monitor may be ready for the market before DAC. Ultimately, Monitor’s innovations will serve as a stepping stone toward full DAC implementation.

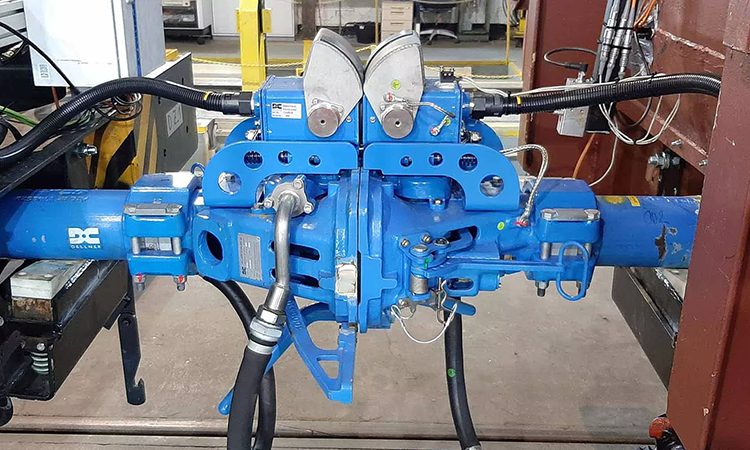

Credit: SNCF

What would you say to organisations that still have reservations about DAC and how might these concerns affect its deployment?

DAC’s advantages extend beyond single wagonload operations to the broader rail freight sector”

Yes, we know that some organisations have reservations about DAC and its deployment. First, it’s important that we listen to these concerns carefully. There are three main areas of concern: the reliability of the system, funding and deployment strategies.

In terms of reliability, the goal of the Trans4m-R project is to develop and test the DAC technology thoroughly. By the end of the project, we should be able to demonstrate that DAC is reliable, even if it includes electronic players like e-couplers. The second concern, funding, is a big issue. As I mentioned earlier, while the European Commission has taken an important first step with the CEF call for the Pioneer Train phase, discussions about the funding are still ongoing and nothing has been fully confirmed yet for the full deployment phase.

Finally, regarding deployment, while some initial deployment scenarios have been defined, these could be looked at again and revised based on the results from the Pioneer Train phase. This phase could lead to adaptations in the current DAC system and possibly changes in the deployment strategy. Additionally, some stakeholders are concerned that DAC may only benefit railway undertakings that operate single wagon trains. However, this is not the case. Features like the automated brake test will provide clear benefits for all types of rail freight traffic including intermodal, as they will significantly reduce train preparation time. DAC’s advantages extend beyond single wagonload operations to the broader rail freight sector.

Discussions between the European Commission, the EDDP, the Trans4m-R project, and concerned organisations are ongoing. We believe that by working together, we can find solutions that will benefit the entire sector.

Finally, looking ahead, how do you envision the rail freight sector evolving over the next decade with innovations like DAC, and what role will Rail Logistics Europe play in shaping that future?

Beyond DAC, RLE is also committed to making rail freight easier for customers to use. Simplifying the process will help retain current customers, expand their traffic and attract new customers”

This is probably the most difficult question. First, we are confident that the share of rail freight will increase in the future, as rail is an obvious solution for managing the ecological transition, as it significantly reduces the carbon footprint of the transport modes. DAC is an enabler for improving the performance of the rail freight sector, which will help the growth of rail traffic.

One key benefit of DAC is that it will allow us to use existing infrastructure more efficiently, enabling more trains to run on the same tracks. We know that significant investment in new infrastructure will be difficult, so increasing efficiency is important. Just as a reminder, every euro invested in rail freight saves an equivalent euro in externalities for society, so it’s vital to support investment in the rail freight sector and the implementation of DAC.

Beyond DAC, RLE is also committed to making rail freight easier for customers to use. Simplifying the process will help retain current customers, expand their traffic and attract new customers who might otherwise see rail as too complex. We are also focusing on reducing our environmental footprint further, despite already being a low-impact transportation mode. This includes projects aimed at reducing energy consumption during train operations and exploring greener fuels for non-electric locomotives. For example, we are conducting trials in France with Hydrotreated Vegetable Oil (HVO) fuel in partnership with customers like Eqiom. We plan to expand such trials to continue lowering our carbon footprint.

Overall, Rail Logistics Europe aims to play a leading role in shaping a more efficient, sustainable and customer-friendly rail freight sector over the next decade.

OUT NOW: The Definitive Guide to Rail’s Digital Future

The rail industry is undergoing a digital revolution, and you need to be ready. We have released our latest market report, “Track Insight: Digitalisation.”

This is not just another report; it’s your comprehensive guide to understanding and leveraging the profound technological shifts reshaping our industry. We move beyond the buzzwords to show you the tangible realities of AI, IoT, and advanced data analytics in rail.

Discover how to:

- Optimise operations and maintenance with real-time insights.

- Enhance passenger services through seamless, high-speed connectivity.

- Leverage technologies like LEO satellites to improve safety and efficiency.

Featuring expert analysis from leaders at Nomad Digital, Lucchini RS, Bentley Systems and more, this is a must-read for any rail professional.

Related topics

Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Freight, Safety, Sustainability/Decarbonisation