Leveraging open telemetry and AI for predicting and optimising wheel life and performance for railroads

Posted: 1 July 2024 | Subhadip Kumar | No comments yet

Subhadip Kumar, Independent Railroad Researcher, explores the future opportunities and challenges of using machine learning and AI for prognostic and health management (PHM) of rail wheels.

Prognostic and health management (PHM) is a rapidly developing field that leverages sensors, real-time monitoring, advanced cameras, and drones to enhance the performance and safety of rail systems. Wheel replacements account for about 60% of railcar maintenance costs, and wheel profile data is crucial for determining wheel life productivity. This paper demonstrates how artificial intelligence (AI) can be applied to analyse wheel profile data and optimise wheel maintenance strategies. The paper shows how AI can reduce maintenance costs, improve operating ratio, detect wheel wear in a timely manner, and prevent accidents and derailments. The paper also discusses the future opportunities and challenges of using AI for PHM in the rail industry.

Rail transportation is a vital component of the North American economy and society, connecting people and goods across vast distances and diverse terrains. North America has a vast and diverse railroad network that spans across three countries: the United States, Canada and Mexico. The network is composed of different classes of railroads, based on their operating revenue and size. The largest and most dominant class is Class I, which includes six freight railroads and one passenger railroad. These railroads own their own tracks and operate over long distances with minimal stops. They account for most of the freight rail mileage and revenue in North America. Class I railroads are followed by Class II and short line railroads, which are smaller and serve regional or local markets. Lastly are metro or rapid transit lines, which provide urban and suburban mobility for millions of commuters.

All these rail systems share a common element: the wheel, which is the interface between the railcar and the track, and which determines the performance, safety, and efficiency of the rail transportation. However, the wheel is also subject to various types of wear and damage, which can affect its functionality and lifespan. Wheel wear can be either homogenous or irregular, depending on the type of wheel and rail, the operating conditions, and the maintenance practices. One of the common and severe forms of irregular wheel wear is polygonization or harmonic out-of-round (OOR), which is characterised by periodic irregularities on the wheel circumference. Polygonization can cause noise, high frequency vibration, and derailment, posing serious threats to the rail system and its users. For example, in 1998, the German inter-city express (ICE) had a catastrophic derailment near Eschede, which was attributed to wheel polygonization and resulted in 101 fatalities and 88 injuries. In another incident, a Norfolk Southern train carrying hazardous materials derailed near the border of Ohio and Pennsylvania, in the small town of East Palestine, sparking a media frenzy. Out of the 36 cars that went off the tracks, 11 had hazmat cargo. The authorities evacuated the locals and the EPA cleaned up 88,500 tons of waste and 28 million gallons of water. A faulty wheel bearing was the likely cause of the accident, according to the NTSB.

To prevent and mitigate the effects of wheel wear, rail operators need to monitor and measure the wheel profile data, which includes parameters such as flange height, flange thickness, rim thickness, hollow tread, and axle data. These data can provide valuable information on the condition and performance of the wheel and help determine the optimal time and method for wheel maintenance or replacement. Modern railways use wayside laser-based wheel profile measurement systems to collect wheel profile data, as well as equipment health monitoring systems (EHMS) to collect data on repair history, mileage and wheel profile detector (WPD) data.

However, collecting and analysing wheel profile data is not a trivial task, as it involves large volumes of data, complex interactions, and uncertainties. Therefore, there is a need for advanced methods and tools that can leverage the power of machine learning and artificial intelligence (AI) to process and interpret the wheel profile data, and to provide reliable and actionable insights for rail operators.

This study aims to address this need by presenting a novel predictive model that can estimate the remaining life of the wheels, trigger a notification or a workflow to order wheels with proper lead time, plan inventory to reduce stockout costs, and ensure regulatory compliance. The proposed model uses a combination of data-driven and physics-based approaches, and incorporates various factors that affect wheel wear, such as wheel type, rail type, operating conditions and maintenance practices. The model is validated using real-world data from North American rail systems and demonstrates significant improvements in operating ratios and spending reduction. The study also discusses the future opportunities and challenges of using machine learning and AI for prognostic and health management (PHM) of rail wheels.

Wheel characteristics

Wheel profile detector data is essential for monitoring the health and performance of train wheels. It consists of several parameters that measure the shape and size of the wheel components, such as the flange, the rim and the tread. Some of the important parameters are flange height, flange thickness, hollow tread and rim thickness. These parameters indicate the level of wear and tear of the wheels and help to determine the optimal schedule for maintenance and replacement. By using this data, rail operators can prevent hazards like derailments, and avoid damage to the tracks and rails caused by excessive wheel wear. The flange is the part of the wheel that protrudes from the rim and keeps the wheel aligned with the rail. It ensures that the train moves in a straight line and can negotiate curves safely. The rim is the part of the wheel that contacts the rail surface. It supports the load and transfers the traction and braking forces. The tread is the part of the rim that faces the rail. It can have a concave shape due to wear, which is called hollow tread. Hollow tread is often considered the most important tread parameter, as it affects the contact area and pressure between the wheel and the rail. The mean dimensions for each of the four critical wheel tread parameters, according to a study, were as follows; 30.5 mm (1.202 in.) for flange height, 35.4 mm (1.395 in.) for flange thickness, 0.483 mm (0.019 in.) for hollow tread, and 37.8 mm (1.488 in.) for rim thickness.

Data collection

Wheel prediction data is essential for assessing the condition and performance of railway wheels. The primary source for this data is a series of wayside detectors that are installed along the track. These detectors measure various parameters of the wheels, such as profile, temperature, sound, bearing and cold wheel detection. The wheel profile detectors capture the shape and wear of the wheel tread and flange, which affect the contact and friction with the rail. The wheel temperature detectors monitor the heat generated by the wheel-rail interaction, which can indicate excessive braking or sliding. The acoustic detectors record the noise emitted by the wheel, which can reveal defects or cracks on the wheel surface. The bearing detectors detect the vibration and temperature of the wheel bearings, which are crucial for the smooth rotation of the wheel. The cold wheel detectors identify the wheels that are not rotating properly, which can cause flat spots or damage to the rail. Wheel Impact Detectors detect wheel defects or wear by measuring the stress on the wheels caused by the track. By collecting and analysing the wheel prediction data from these detectors, railway operators can optimise the maintenance and safety of the wheelsets.

Figure 1: Wayside detector

Descriptive and predictive analysis of wheel characteristics

Cloud computing has revolutionised the way data can be processed and analysed, especially for complex and large-scale applications. One such application is the wayside sensors data, which captures the condition and performance of the railway wheels. This data can be used to perform predictive analysis and prevent failures or accidents. However, the wayside sensors data is often scattered and heterogeneous, requiring a lot of preprocessing and integration. This is where cloud computing can help, by providing tools and services that can handle the data extraction, transformation, and loading (ETL) process, as well as the data analysis and modeling process, in a fast and efficient way.

In this article, demonstrated AWS, a leading cloud provider, to analyse a raw dataset of 433,571 rows of wayside sensors data. The dataset was stored in an S3 bucket, a scalable and secure cloud storage service. AWS Glue, a serverless data integration service helped to extract the data from the S3 bucket and transform it into a suitable format for analysis. AWS Athena was leveraged to query the transformed data [Figure 2]. AWS Sagemaker, a comprehensive machine learning service was used to query and analyse the data from Athena. Sagemaker Canvas, a low-code/no-code tool was utilised, to create a data flow that cleaned and loaded the data for building a predictive model. Sagemaker was also used to explore the characteristics and insights of the data, such as the distribution of wheel defects, the correlation between wheel temperature and impact, and the impact of crew and dispatch schedules on the wheel condition.

The entire exercise was done without writing any backend code, thanks to the low-code/no-code features of AWS. This shows how cloud computing can simplify and accelerate the data analysis process and enable us to get a holistic picture of the wayside sensors data and perform a predictive analysis. This can help us to generate real-time alerts to the locomotive engineer and crew about any anomaly and improve the safety and efficiency of the railway operation.

Figure 2: Athena query on the sensor data

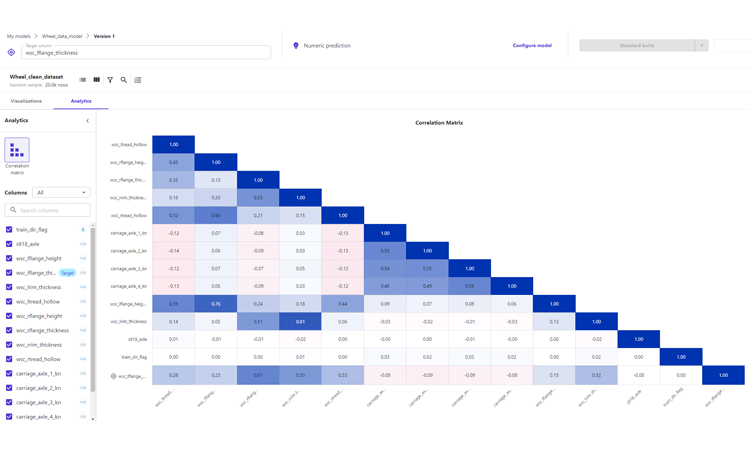

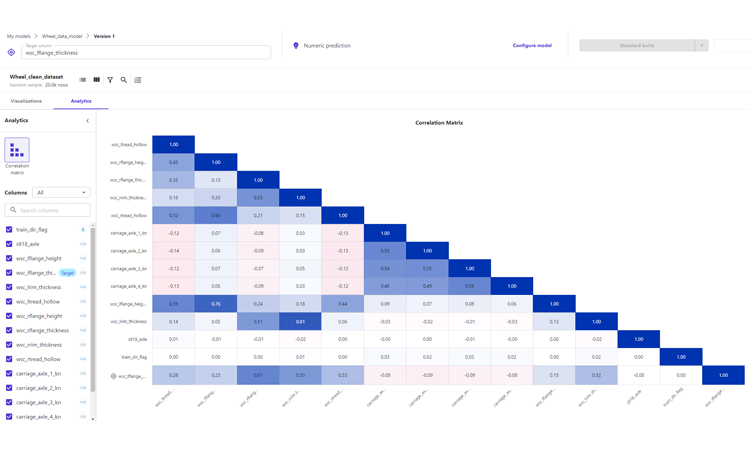

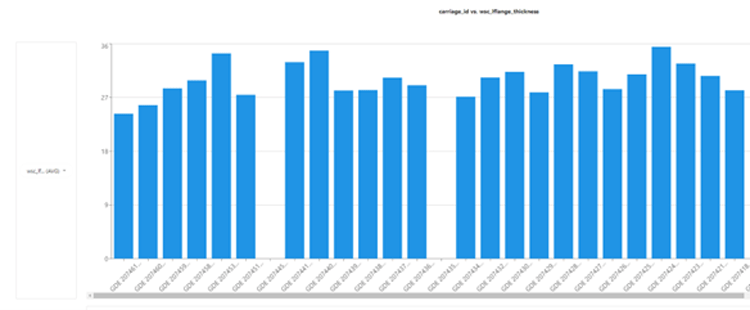

To understand the relationship between several components of wheel profile data correlation matrix was built [Figure 3]. This reveals some interesting features like hollow tread is somewhat correlated to flange height and rim thickness is correlated to flange thickness.

In another graph [Figure 3a], average flange thickness was plotted to see which rail car wheels are due to be replaced.

Future roadmap

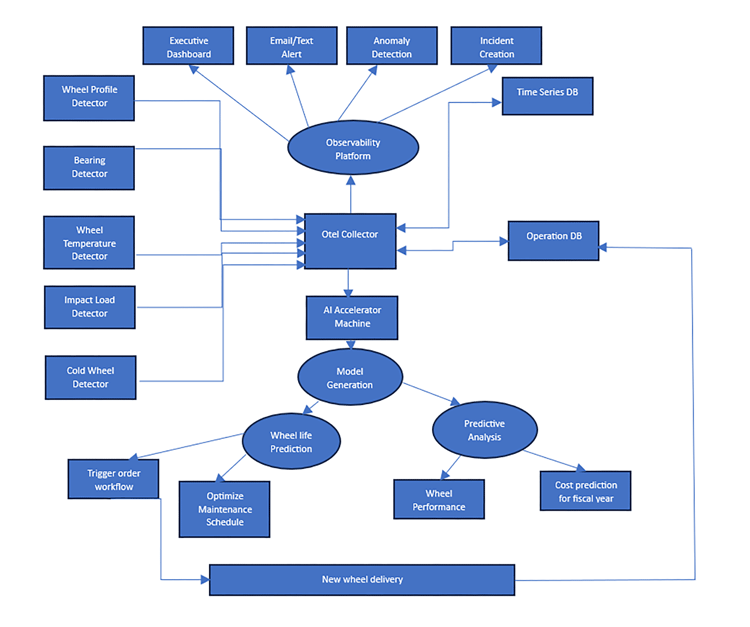

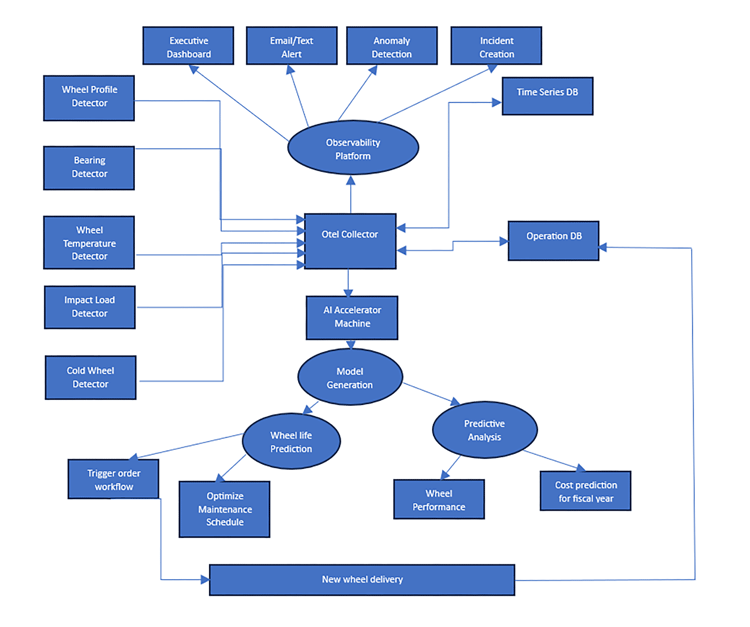

The health of a wheel is a crucial factor for the safety and performance of a vehicle. However, different sensors may capture different aspects of the wheel condition, such as its shape, temperature, sound and impact. How can these diverse data sources be integrated to get a comprehensive picture of the wheel health? This was a challenging task until recently, as it required a lot of backend work to bring all the systems under the same platform, and to perform various data transformations and analyses to generate meaningful insights. However, with the development of the open telemetry framework, this task has become much easier and more efficient. Open telemetry is a platform‑independent framework that allows multiple sources of truth (telemetry data) such as sensor data, logs, traces, and events to be combined and defined as an observability platform. It also provides APIs, SDKs, and tools to instrument, generate, collect, and export telemetry data to various analysis platforms. The proposed architecture uses open telemetry to create an observability platform for different wheel characteristics data, such as wheel profile detector data, wheel temperature detectors, acoustic detector, and wheel impact detector data. The proposed architecture also sets up different workflows to trigger alarms or work orders when the wheel is nearing the end of its life depending on the severity. This way, the proposed architecture can monitor and maintain the wheel health in a proactive and effective manner.

Figure 4: Future architecture

In this proposed architecture [Figure 4], several wheel profile data are being ingested to the otel collector using open telemetry protocol. The observability platform then pulls that data and produces meaningful insights and actions. The data will then be enriched with operational databases and time-series DB. Everything will be collected in Otel collector. With the help of observability, site engineers can understand the health of the wheel, and correlate the events from several different collectors. The observability platform can help the site engineers, locomotive engineers and conductors to make augmented decisions, detect any anomalies in real time and move from reaction to prediction. The observability platform can produce an executive safety dashboard in real time or email it out every morning. The observability platform can also trigger email and text alerts depending upon the priority and notify the control center and/or train crew.

The telemetry can also be fed to the AI accelerator, which can use machine learning and deep learning techniques to build predictive models for the wheel life. The AI accelerator can help to optimise the maintenance schedule and the replacement order for the wheels, based on the estimated remaining life and the vendor’s historical turnaround time. The system can trigger an automatic work order to process the replacement order. Once the order is received and stacked, the system can also trigger a maintenance schedule for the railcar. Finally, the operation database will be updated so that future models can produce more accurate data. By using this architecture, spending, and labour for the forthcoming fiscal year can also be predicted and resources and budget can be arranged in advance. The proposed architecture has several benefits, such as:

- It eliminates the vendor dependency by using a vendor-neutral framework (open telemetry)

- It leverages the support from an enriched open‑source community

- It decreases the maintenance spending by limiting early wheel replacement as the AI platform can accurately estimate the remaining life

- It eliminates manual errors and helps to take augmented decisions

- It reduces stockout costs and carrying less inventory and saves real estate space which can otherwise be better utilised

- It boosts the operating ratios by achieving huge cost savings

- The proposed architecture can also benefit different classes of railroads, such as class I, class II, and short-term railroads, by providing a cost-effective and scalable solution for managing the wheel health.

Solutions that are compatible with open telemetry are offered by several vendors. One such vendor is Inmarsat. Partner solutions are provided by SAS and Kaviglobal and offer similar solutions. Wabtec entered this niche market and introduced a railcar telematics solution in the first quarter of 2024. Few different architectural solutions are also available from Argus (a Caterpillar Company) and Siemen’s Train IT solution.

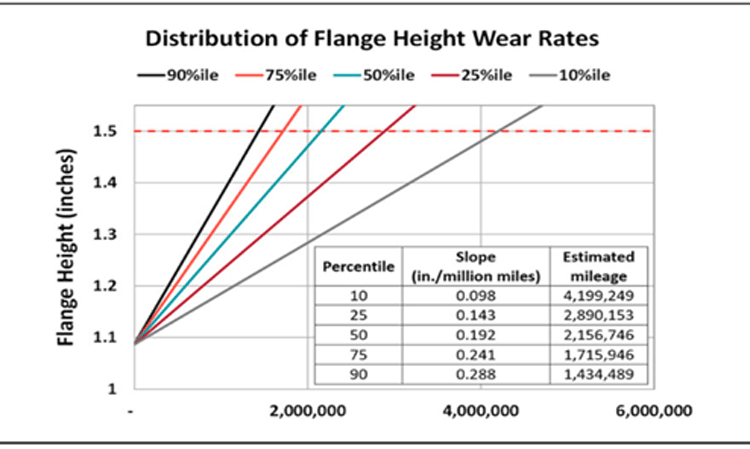

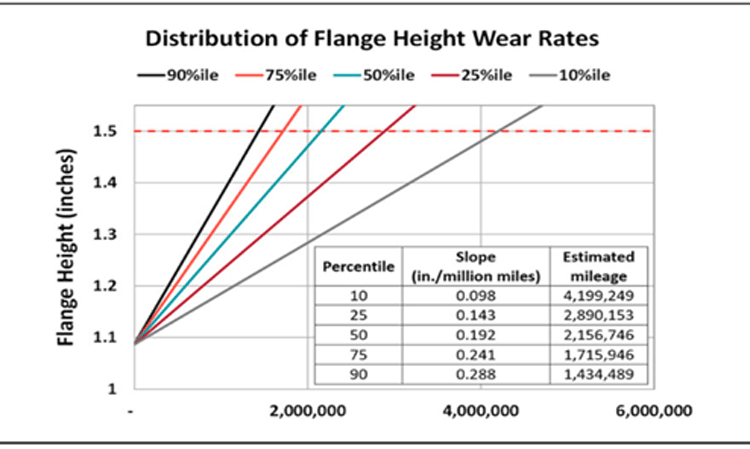

MxV RAIL R&D also performed a similar experiment and was able to estimate the wear rates of the flange height accurately.

Figure 5: Flange height wear prediction by MxV Rail R&D

The article discusses how the wheel profile data, which is collected from various sensors and systems, can be leveraged to improve the management of the wheel health for the railroads. The article introduces the concept of open telemetry, which is a framework that allows the integration and collection of different types of telemetry data, such as sensor data, logs, traces, and events. The article also explains how AI can be used to analyse the telemetry data and generate predictive models for the wheel life, which can help to optimise the maintenance schedule, the replacement order and the performance of the wheels. The article claims that by using open telemetry and AI, the railroads can achieve several benefits, such as reducing the maintenance costs, the inventory costs, and the real estate costs, as well as increasing the safety, reliability, and efficiency of the wheels. The article also provides some examples of vendors and solutions that support open telemetry and AI for wheel health management. The article concludes by highlighting the potential of open telemetry and AI for the railroads and the challenges that need to be addressed.

References

1. Cremen, A. (2023, February 28). Replacing 7000-series railcar wheels may take years, cost $55M.

2. Tao, G., Wen, Z., Jin, X., & Yang, X. (2020). Polygonisation of railway wheels: a critical review. Railway engineering science, 28, 317-345.

3. Brumsen, M. (2011). Case description: the ICE train accident near Eschede. In European business ethics cases in context: The morality of corporate decision making (pp. 157-168). Dordrecht: Springer Netherlands.

4. Walker, M., Eavis, P. (2023, June 29). N.T.S.B. Convenes Hearing in East Palestine to Examine Train Derailment. The New York Times.

5. Lee, J., Dersch, M. S., Lima, A. D. O., & Edwards, J. R. (2023). Probabilistic review of wheel profiles based on hollow tread in the U.S. heavy haul rail network. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 237(4), 508-516. https://doi.org/10.1177/09544097221122030

6. Shin, S., Jin, A. H., Yoo, S., Lee, S., Kim, C., Heo, S., & Kang, N. (2023). Wheel impact test by deep learning: prediction of location and magnitude of maximum stress. Structural and Multidisciplinary Optimization, 66(1), 24.

7. Hartwich, D., Müller, G., Meierhofer, A., Obadic, D., Rosenberger, M., Lewis, R., & Six, K. (2021, August). A Fast, Reliable and Practical Method to Predict Wheel Profile Evolution. In The IAVSD International Symposium on Dynamics of Vehicles on Roads and Tracks (pp. 552-560). Cham: Springer International Publishing.

9. Oliveira, David (2018). Wheel set profile [Dataset]. Dryad. https://doi.org/10.15146/R3XD4K

10. Luczak M. (2021, December 9). By the wayside. Retrieved from https://www.railwayage.com/cs/by-the‑wayside/ 11. Santos, J. (2023, March 10). What is an OTEL collector? LogicMonitor. Retrieved April 6, 2023, from https://www.logicmonitor.com/blog/what-is-an-otel-collector

12. Kavi Global. (2023). Wheel life productivity: A case study. SAS. Retrieved April 6, 2023, from https://www.sas.com/content/dam/SAS/documents/briefs/third-party/en/sas-kaviglobal-wheel-life-productivity.pdf

13. Witte, M. (2024, January 8). Predicting wheel wear. Railway Age.

Issue

Related topics

Artificial Intelligence (AI), Bogies & Wheelsets, Digitalisation, Operational Performance, Rolling Stock Maintenance, Safety, Technology & Software