Accelerating Intelligence to Lay Foundations for the Future

Posted: 17 November 2023 | | No comments yet

The digital railway brings many advantages: It enables the use of better train control systems, allowing trains to run closer together and so enhancing capacity; at the same time, safety is improved with drivers having signalling instructions, commands and authorisations displayed on the control panel in front of them.

In addition, driver advisory systems calculate the most efficient way to drive the train, saving fuel and further enhancing safety. These automatic systems can even take over control of the train, for either all or part of a journey, optimising acceleration, deceleration and dwell times in complex and high-capacity timetables.

However, this advanced technology creates its own demands. Train control systems need to run on computers in the control centres – either proprietary CBTC (computer-based train control) or internationally standardised systems such as ETCS (European Train Control System). The same system needs to be running on the train’s on-board computers. If that train moves between different control systems, or across national borders, it may need to have the capability of running several incompatible systems and switching seamlessly from one to the other.

Whatever the actual digital system employed, there is one essential component that is needed – excellent and secure communications between the train, wayside beacons and the control centre. Without this, digital train control systems simply will not work.

The most commonly employed railway communication technology is GSM-R – the railway-specific version of conventional mobile phone technology. It has some additional features, such as group communication, location dependent addressing, priority levels, railway emergency calls and shunting communication, but it is basically a conventional GSM (Global System for Mobile Communications) telephone network.

GSM-R is also old technology, being based on 2G (second generation) communication standards, which were first launched in 1991. These were replaced by 3G (launched commercially in 2002), which offered greater bandwidth and network capacity. 3G has since been replaced by 4G (2009) and 5G (2016).

But railway communications have remained firmly locked into the 1991 2G standard. As signalling and control systems have become more advanced, and therefore more demanding on bandwidth and capacity, GSM-R has started to struggle.

FRMCS: The next-generation solution

The UIC (International Union of railways / Union Internationale des Chemins de fer), as custodian of the GSM-R standards, started work on its Future Railway Mobile Communication System (FRMCS) solution in 2012. Collaborating with standards organisations including the European Telecommunications Standards Institute (ETSI) and 3rd Generation Partnership Project (3GPP), as well as railway companies around the world, FRMCS was developed both as the successor of GSM-R and as a key enabler for rail transport digitalisation. The first Global FRMCS Conference took place on 14-15 May 2019 in Paris and international suppliers started to develop their own versions of the new technology.

A high level of reliability is a feature of Huawei’s FRMCS solution, with redundancy built into the hardware at circuit board, device and network level. Its LTE broadband technology supports up to 20Mbps data transmission, making the technology ideal for railway applications.

Mozambique: Revolutionising Crucial Communication

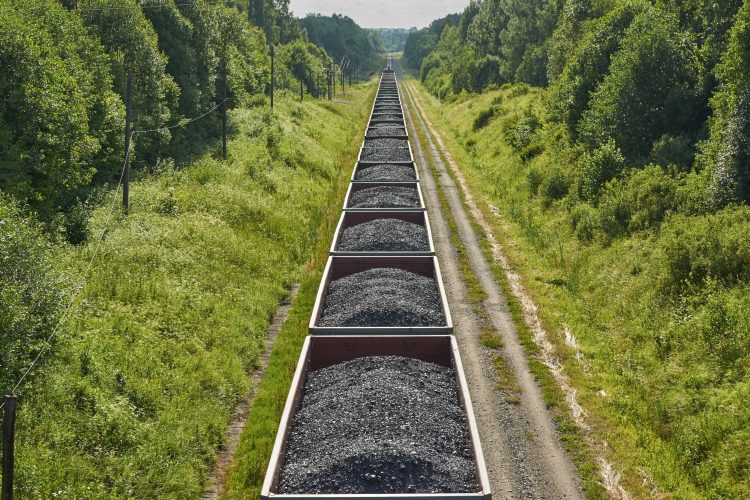

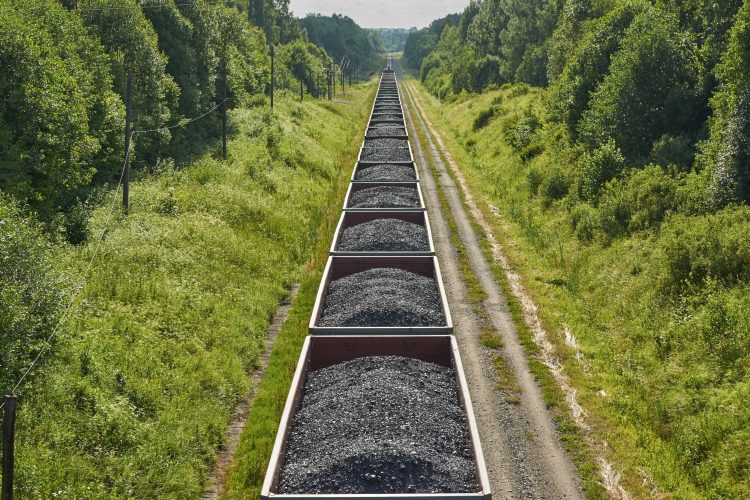

One of the first deployments for Huawei’s advanced FRMCS system has been on the railways of Mozambique. Located on the Indian Ocean in Southern Africa, Mozambique is home to several large ports, including Maputo, Beira, and Nacala. From here, nine railway lines ferry goods to other African countries such as South Africa, Eswatini, Zimbabwe, and Malawi.

These ports have unique geographic advantages and are among the main transportation channels for import and export to neighbouring inland countries. Mozambique also enjoys abundant marine resources — it has the largest reserve of tantalum in the world and over 15 billion tons of coal.

The company that maintains and operates Mozambique’s ports and railways is CFM (Portos e Caminhos de Ferro de Moçambique). To build a modern, stable, and sustainable communication system that would ensure reliable train-to-ground voice and data communication, CFM turned to Huawei for both technology and equipment.

In response, Huawei designed a targeted and integrated dispatching communication system based on FRMCS for CFM. This uses an advanced converged communication platform to provide MCX (Mission Critical) wireless broadband trunking and multimedia dispatching communication services. It also supports 3GPP-compliant mobile communication networks and enables future applications defined by UIC FRMCS.

The Huawei solution also It provides panoramic, visualized, and controllable dispatching and commands for dispatching personnel, locomotive drivers and transportation management, improving transportation security and O&M (operation and maintenance) efficiency.

The system quickly transmits real-time high-bandwidth information, unlike its outdated counterpart. This has also reduced the number of security incidents, such as the risk of collisions between freight and passenger trains as well as casualties among railway maintenance personnel.

Since the integrated dispatching communication system adopts an architecture based on international standards, the FRMCS communication system has now laid the technical foundation for modern, high-capacity railways on Mozambique, greatly improving the efficiency of scheduling, safe operation and employee management. The freight volume of the Port of Maputo has increased from 22 million tonnes in 2021 to 26.7 million tonnes in 2022 and is expected to exceed 30 million tonnes in 2023.

Accelerate Intelligence with cutting-edge ICTs

Huawei’s advanced replacement for GSM-R is just part of the work the company is doing in accelerating intelligence for the railway industry. Next-generation ICTs (Information and Communication Technologies) will be the foundation for the railways of the future, which will offer secure, efficient, and green experiences for both passengers and freight. Leveraging its own cutting-edge ICT solutions, and working closely with partners and customers, Huawei is helping to build a smarter railway industry.

Apart from the aforementioned FRMCS solution, the future of the railway industry is already digital and will increasingly be dependent on the use of intelligent solutions, allowing systems and their users to learn and develop as systems and strategies evolve.

Huawei’s intelligent Train Freight Detection System (TFDS) Solution has also helped China Railway Zhengzhou Group to speed up train operations. Leveraging the advanced Huawei Pangu Railway Model, the solution is helping the 5T inspection workshop of Zhengzhou North Rolling Stock Depot to enhance working efficiency by 200%, improve the fault identification rate to 99.3%, and speed up train inspection. Zhengzhou Group can now overhaul trains with a higher intelligence level and save operational costs by tens of millions of yuan. With manual inspection replaced by intelligent identification, the Group can proactively avoid train driving risks and ensure smooth train operations.

Examples of this work, and how Huawei’s Smart Railway Solutions are driving the railway industry towards digitalisation, were on the agenda of the recent Huawei Connect 2023 event on Accelerating Intelligence, held in Shanghai, China, on 20-22 September 2023.

At a time when the rail industry is coming to realise the scale and importance of digitalisation and the role these forms of technology pose to play in the future, it is integral to have case studies to forge a path that others can follow. Huawei’s willingness to share their knowledge is a source of inspiration and power for the whole industry.

Click here to know more about Huawei’s Smart Railway solutions.