HATI: The key to the future of autonomous MATISA machines

Posted: 5 April 2022 | MATISA Materiel Industriel SA | No comments yet

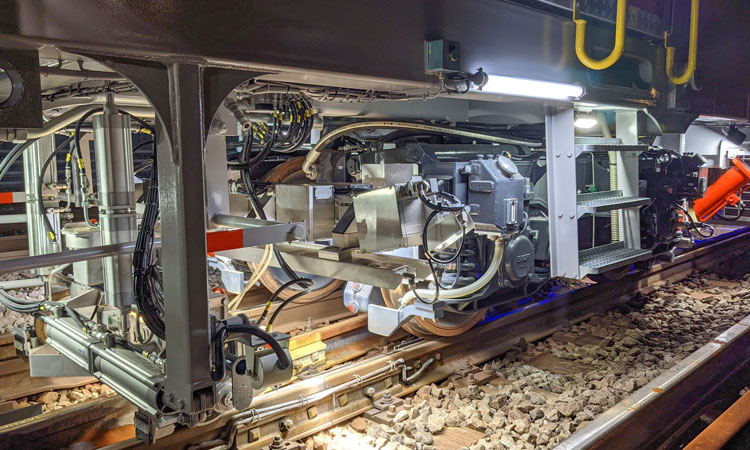

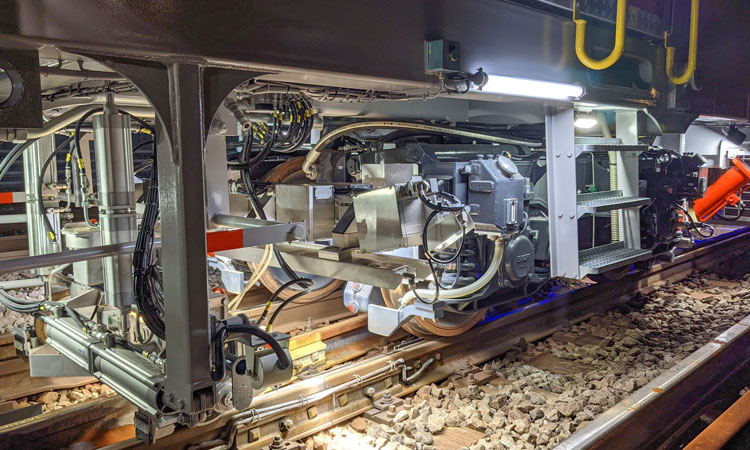

HATI (Human Assistance Track Intelligence) is the latest addition to the MATISA embedded technology family. It is the evolution of a system already installed on the roller trailers of the B 66 UC-D compaction trailers, with the addition of new features. A prototype was installed on the B 45 UE delivered to one of our customers in Japan in the first half of 2021.

Target groups

MATISA has the will to go in the direction of the objectives of its customers; we will answer the contractors who are conscious about reducing CO2 emissions with our products. One way to meet this objective will be with HATI, which allows for the detection of obstacles to reduce costly damage to infrastructure and machinery.

This will be followed by making the machines increasingly autonomous. The analysis of events on the track and the management of the machine performance will also allow for improvements to the performance of the work processes.

The HATI system is intended to be installed on tampers and renewal machines. Only new machines, or complete retrofits, will allow the installation of this system.

Highlights and description of the HATI system

HATI has the following four important features:

- Acquisition during the work of obstacles1

- Measuring of the track1

- Management of the automatic machine advance and optimal tool positioning

- Assistance to the operator during work by displaying the track image and visualising the location of the tools.

Acquisition during work

The acquisition can be done during the work. During this phase, the system identifies and locates track elements such as sleepers, fastening, beacons, switches and guard (check) rails. However, the identification and classification of new types of elements is not automatic. It will have to be analysed by the development team, who will then decide whether to add the new class of elements to the system or not. This process will involve the collection of several image sequences, including the new object to be recognised.

The system is also able to detect unconventional obstacles2 on the track and identify and classify them by learning to recognise them through artificial intelligence (AI) algorithms.

Measure

A track measurement module allows the acquisition of diverse parameters.

Positioning of the machine and tools

HATI calculates the steps of the automatic advance of the machine so that the machine can take into account the sleeper spacing in its cycle and position itself optimally between the sleeper.

In addition, the ideal position. or the motion lock, of each tool is calculated or defined. This information is transmitted to the PLC as setpoint values.

Assistance during work

HATI assists the operator during work by displaying information about track elements and obstacles on a dedicated screen. The operator can validate what is displayed and anticipate the situation on the track a dozen sleepers in advance.

Future developments

HATI, like all embedded systems, will be able to evolve. Software updates will be available and can be installed, although this is only possible if the hardware does not require changes. With future improvements, the following elements are planned:

- Pre-acquisition

- Improvement and refinement of the accuracy of detection of unknown elements

- Centring of tools for fastening.

For more information, please visit: www.matisa.ch

References:

- The data created by HATI is stored in a database The measures of interest, as well as the form of the report, can be defined with the customer.

- Still unknown by the system.

Issue

Related topics

Artificial Intelligence (AI), Automatic Train Operation/Autonomous Train Control (ATO/ATC), Big Data, Digitalisation, Track Maintenance Machinery