Developing connectivity solutions to benefit rail operators and passengers

Posted: 26 January 2022 | Daniel Montagnese | No comments yet

Daniel Montagnese, Head of Product Management Antennas at HUBER+SUHNER, speaks with Global Railway Review about the advancements in connectivity solutions that are bringing benefits to both the passenger and the operator, and how antennas are at the forefront of this technology.

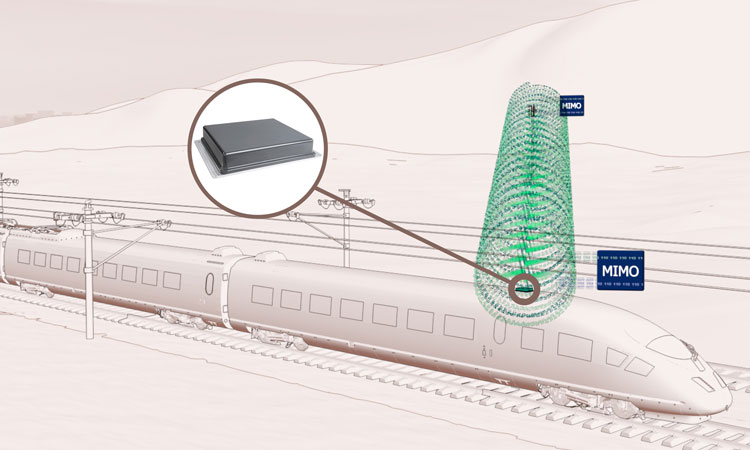

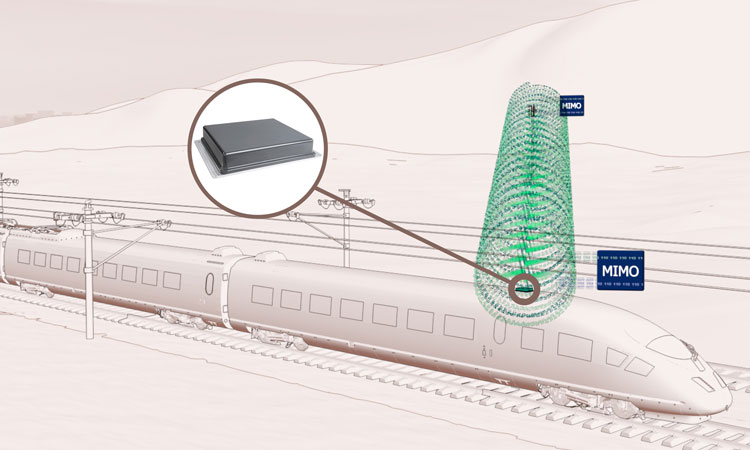

HUBER+SUHNER SENCITY® Rail MIMO+ rooftop antenna increases potential 4G & 5G data throughput.

Why is it important that rail operators invest in connectivity solutions?

Rolling stock presents multiple challenges for mobile public networks. Not only are the trains made from heavy metals like aluminium or steel, train windows are often covered with insulating film which is also metallic in construction. All this metal builds a Faraday cage for the people inside the train, meaning that electromagnetic signals can’t pass from inside the train to the outside. This results in mobile phones or laptops not being able to function or connect to the internet. Needless to say, this is not an ideal situation for a modern-day mode of transport, especially with the many different options the public has available to them to get to work or travel between cities and towns.

Of course, there is the option to drive. But, if you drive you can’t be productive. You could fly, which is often faster, but then you’re faced with security and airport wait times. And once in the air, the passenger often finds they have no signal, or a poor signal which they still have to pay for. Whereas with the train, often there’s no wait time. The passenger gets on, sits down, and can immediately begin their task, providing there’s Wi-Fi. Their commute time can double-up as work time. A train trip across countries to visit family and friends, could provide the chance to plan their trip while en route. Connectivity is a huge part of the value in rail transportation, in terms of the offering to passengers.

At the same time, operators are collecting ever increasing amounts of data. Whether that’s operational data, or video footage inside the train, all of this data needs to be sent back to data centres for processing. Often this data is large in volume, and as such, a good connection is required. Simply building a hotspot inside the train will not suffice, instead dedicated equipment is needed to tackle the way in which train bodies are constructed.

What factors should operators consider when choosing infrastructure?

HUBER+SUHNER SENCITY® RAIL MIMO+ rooftop antenna

Dedicated equipment should absolutely be considered. Antennas are probably the most important piece or component in the system in terms of wireless communication. And yet, the wireless communication link is often the biggest bottleneck in the overall system because it has to transmit, or convert, the signals into electromagnetic waves and then transmit those over the air. The distances between the antennas can sometimes be very large, possibly kilometres. So, it’s vital that the antenna chosen and specified in the system is equipped with the latest technology.

We have recently invested significant R&D into two areas for antennas. One, was in implementing dual polarization technology into our train rooftop antennas. This technology enables a very high decoupling between wireless channels, which then supports MIMO functionality on the electronic equipment. MIMO functionality is a software mode which radios can work in, providing multiple simultaneous streams of data. For example, a 2×2 MIMO system gives double the amount of data rate and 4×4 is four times the data rate. This is the first technology we invested in.

The second technology we have invested in is our active antennas. This is about integrating the electronics into the antenna itself; basically eliminating the need for RF cables. Usually, within the train is the server cabinet which houses the electronic equipment, which is then connected with RF cables to the antennas on the rooftop. This distance could range from one metre to over 10 metres. As RF cables are working with analog signals, the longer the distance, the higher the losses. And this is especially critical as the frequencies get higher, as they do with 5G. At the same time, the cellular technologies for 5G move towards 4×4 MIMO, which means you need twice the amount of RF cables as you would have done with 2×2 MIMO. This takes up a lot of space, requires lots of additional equipment, space for routing the cables, the weight of these cables, and so on.

A lot of operators tell us that RF cables are prone to damage when servicing or maintaining the rolling stock. Simply stepping on, or bending, an RF cable, could see the connection broken, and then the whole signal lost between the antenna and the radio. So, the active antenna brings the radio into the antenna on the rooftop and the whole system is powered via ethernet cables, which is a single cable providing all the connectivity that’s needed to the train backbone.

As 5G connectivity is introduced on trains, who will benefit?

4×4 MIMO 5G Dual Polarised with L1+L2+L5 GNSS

Without doubt, passengers will benefit because they can be more productive. The best possible connection will enable the reality of seamless working while commuting.

Equally, we are increasingly seeing the opportunity for operators to benefit, not only through improving the value proposition of railway transport for passengers, but also data collection. Trains are starting to resemble mobile data centres, where all of the equipment is transmitting its state, its operational hours or its condition back to the train’s main server. Often, it’s too much data for a server to handle, and it has to be offloaded quite regularly. Offloading huge amounts of data frequently requires a very good connection.

Monitoring is expanding beyond the train body, for operators. We’re seeing video cameras being installed to monitor track conditions, looking at things like vegetation levels, whether the pantograph and catenary lines are in need of service, and so on. The benefit of such monitoring is clear – operators can harness these tools to improve the reliability of their services, to everyone’s benefit.

What is HUBER+SUHNER doing to enable next generation rail connectivity?

HUBER+SUHNER has invested in antenna technologies, firstly with dual polarisation technology to enable MIMO support which improves data rates for traditionally installed communication systems on trains. Secondly, we have invested in active antenna technology, which simplifies the system architecture on trains by integrating the electronics into the antenna itself. This active antenna was a collaboration with McLaren Applied, who developed the electronics for us, which we then integrated into our product. We offer this product to the market, to all system integrators and operators and OEMs, in two options. One is without any software so that they can run their own applications, and the second is via McLaren Applied, where they offer their Fleet Connect software, which is a full routing suit for the antenna. Looking ahead to next year, we will continue our R&D into antenna technologies. This will entail investing in the field of track side equipment for those infill situations where the public network just isn’t good enough or is too unreliable to use traditional antenna systems. This will be based on Wi-Fi technology, rather than cellular. Here, we’re developing new antenna technologies for both the train rooftop and also for the track mounting itself.

Related topics

5G, Big Data, Infrastructure Developments, Passenger Experience/Satisfaction, Signalling, Control & Communications, Technology & Software, Wi-Fi