Digital Automatic Couplers: Dellner’s solution to coupling automation

Posted: 21 April 2021 | Dellner | No comments yet

Dellner’s Digital Automatic Couplers will increase the productivity and competitiveness of rail freight transport as well as contribute to achieving European sustainability targets.

Focus on freight transport

In this extraordinary time, 2021, when safety is of particular importance, we are celebrating the European Year of Rail, which aims to promote railways as a safe, sustainable and intelligent mode of transport. This initiative is part of the European Union’s (EU) efforts under the European Green Deal, a plan to make the economy more sustainable by reducing carbon dioxide emissions by 90 per cent by 2050.

One of the main objectives of the plan is to develop greener modes of transport, as the transport sector is currently responsible for around 25 per cent of greenhouse gas emissions in the EU.

Research shows that rail is responsible for less than one per cent of transport-related greenhouse gas emissions in the EU. This makes rail one of the most sustainable forms of passenger and freight traffic.

Despite these evident advantages and benefits of rail in relation to other modes of transport, it should be stated that, in Europe, only about seven per cent of passengers travel by rail. Then, when it comes to rail freight, their share in total transport is still falling and currently amounts to about 10 per cent of the total volume of transported loads.

The European Year of Rail will provide an impetus to increase the industry’s share in both passenger and freight transport, which, for many years, has not been the subject of sufficient investment.

Coupling automation as one of the goals of the Shift2Rail programme

As part of the European Green Deal, in 2014, the EU established a public-legal partnership – Shift2Rail – to design, coordinate and conduct research and innovation activities in relation to passenger and freight rolling stock, traffic management systems and rail infrastructure.

One of the objectives of the consortium is to reduce the lifecycle costs of rail transport to increase its competitiveness with road transport, to double the amount of rolling stock and to increase its reliability and punctuality. One of the activities undertaken is the standardisation and digitalisation of couplers in freight rolling stock.

Previously, in Europe, screw couplers have been used on freight wagons, which require manual connection and disconnection for each operation of coupling and uncoupling the wagons. This is an extremely dangerous task for the train worker because, regardless of the weather conditions, the worker has to go under the buffers, into the high-risk area between the wagons. From there, the hook and loop bolt is hooked and tightened, as well as the brake lines being connected manually. Upon completion of the operation, the work must then move from the area between the carriages onto the track, exposing themselves to one more risk.

The implementation of new, fully automated couplers is planned in several stages:

- Level 1 – simple mechanical connection, similar to the functionality of those used in other markets

- Level 2 – automatic brake line connection

- Level 3 – automatic connection of electrics

- Level 4 – automatic digital connection

- Level 5 – fully automatic coupler that can be remotely triggered.

The Shift2Rail programme assumes the installation of approximately one million automatic couplers between 2025-2029 on new and old freight fleets.

Dellner as one of the participants of the Shift2Rail programme

Dellner is one of four companies that were invited to design and deliver new Digital Automatic Couplers (DACs). After comprehensive tests on the first generation of the DAC coupler, Dellner moved to the second generation, with modified draft gear and optimised weight.

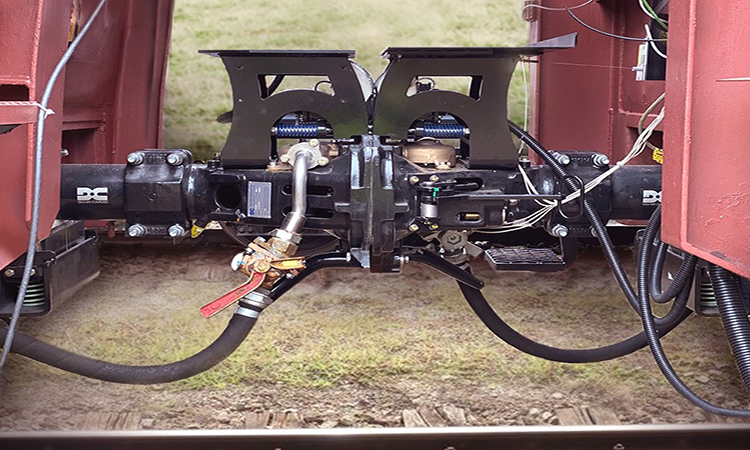

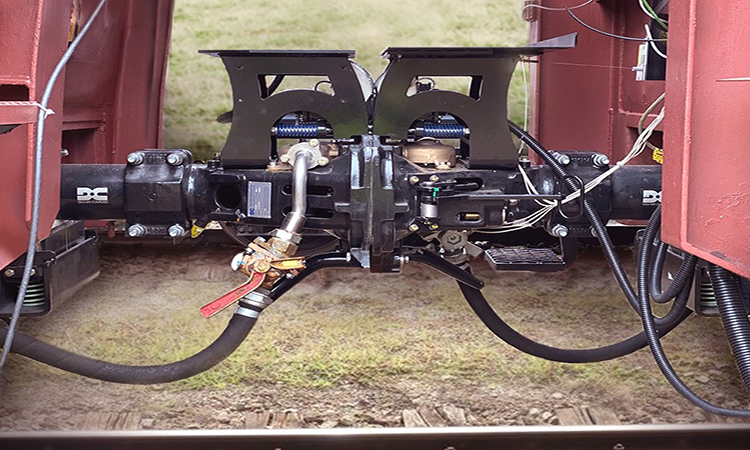

Dellner’s solution is based on a latch coupler head, of which the reliability, safety and durability have been tested on passenger trains in several extreme environments. It provides the possibility of connecting cars in tight curves and of different heights, without needing manual intervention. It is easy to maintain, as the head design allows for lubrication even when the heads are coupled. If the exchange of coupler heads is needed, it can be carried out due to the robust socket joint interface used to connect the coupler head to the draft gear shank.

One of the unique features in Dellner’s DAC is the use of the balanced draft gear, which secures excellent energy absorbing performance. The whole system uses elastomers, which are separated by metal plates working independently of the frame, which subsequently reduces noise level when in service.

The Dellner DAC coupler during tests in Germany. Credit: Dellner

It is derailment optimised, so it provides increased safety during operations. Another important advantage of this solution is that it is designed to be lubrication-free and, therefore, ‘maintenance-free’ throughout its expected life.

Dellner has considered easy mounting as one of the main requirements and therefore proposes a flexible joint incorporated in the draft gear for a quick and easy installation in a UIC 530 standard coupler pocket.

The Dellner DAC coupler and other solutions proposed by the suppliers invited to the programme are currently being tested on wagons in Germany and Sweden. The purpose of testing all solutions is to check their technical functionality in accordance with the requirements and operability in various weather conditions. All tests will take approximately 10 to 18 months. After their completion, Shift2Rail will decide on the type of coupling head and other additional functionalities for the remaining elements of the coupling.

The huge number of DAC couplers that will need to be replaced in a very short time, within five years, will require smart sourcing and improved logistics concepts. Dellner is already working on optimising the costs of this project. This is a great opportunity for the company to gain experience and enter a new customer segment.

Sustainable development

Shift2Rail aims to double rail freight transport and reduce carbon dioxide emissions from road transportation by 110 million tonnes. Replacing screw couplings will help rail freight to become more competitive with road transport, reducing its use and emissions.

All sustainable initiatives are undertaken by Dellner with great commitment, as they are in line with its sustainable development strategy. The continuous improvement of processes and minimising the negative impact on the environment by preventing pollution and improving the efficiency of the resources used – including energy, water, packaging and other raw materials – is all part of Dellner’s daily goals.

Turning climate and environmental challenges into new opportunities in different markets is an opportunity for freight rail to grow. After years of investing in passenger infrastructure, it’s time to see the great development of rail freight.

As a company with an established position as a reliable supplier and business partner that has been connecting trains in a reliable and safe way for 80 years, Dellner contributes with great commitment to the development of rail freight in Europe.

Related topics

Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Operational Performance, Rolling Stock Components (Interior/Exterior), Safety, Technology & Software

Related organisations

Dellner, European Union (EU), Europe’s Rail Joint Undertaking (EU-Rail)