Fret SNCF’s rail freight revolution

Posted: 15 September 2020 | Bertrand Minary | No comments yet

Bertrand Minary, Fret SNCF’s Chief Innovation and Digital Officer, Rail Freight & Intermodal Division, discusses Fret SNCF’s approach to a total revolution in rail freight operations and how this is delivering a first step towards rail freight automation.

With 2021 just a few months away – the year which the European Commission (EC) proposes to be the European ‘Year of Rail’ – and with progress already being made to deliver the European Green Deal – the EC’s roadmap for making the European Union’s (EU) economy sustainable – rail freight is resolutely a political priority for the EU.

Rail freight companies deserve a European contribution to their development. An increase of market share (11.3 per cent in 2017 in the EU 28) compared to road transportation can only happen if there are major efforts to modernise rail freight operations, particularly by significantly improving production efficiency, supported by substantial investments and innovation breakthroughs. Rail’s better environmental performance deserves to be rewarded.

All rail freight stakeholders must be supporters of reinvention”

All rail freight stakeholders must be supporters of reinvention – not only railway undertakings, but also wagon keepers, manufacturers, combined transport operators, forwarders, state bodies, regions and customers, of course.

The situation in France

France is well-known for its railway services, but freight traffic is not a significant part of the French land transport market; only nine per cent of freight is carried by the railway, whilst 85 per cent is carried by road transport. This situation is more the result of the decreases in the sector, energy sources (nuclear) and second-range maritime harbours, compared to Northern ones. There are currently more than 20 companies competing in the French rail freight market.

Fret SNCF (part of SNCF Logistics) is the largest rail freight operator in France and has heavily redeveloped its fundamental elements – including procedures, organisation and services to customers.

Reinventing rail freight: The SNCF approach

Fret SNCF is committed to achieving its ‘freight challenge’ transformation programme, which includes the ‘innovation and digital’ programme. The programme aims to:

- Develop performance based on digital elements with internal and external cooperation and open innovation

- Install a culture of innovation (to inspire and circulate).

Digitalisation and automation are driving the next generation of rail freight

The next generation of rail freight will include a mix of different technologies – most of them are already available to implement and are crucial and precious first steps. These will be combined in the future for autonomous, connected and digital freight trains; all contributing to delivering better services to customers.

The building blocks for automation are:

- Supply chain vision and more efficient operational concepts to address customers’ needs – mutual benefits will be a game-changer

- Digital asset management

- Autonomous freight trains, with ATO and ATS

- Autonomising railway operations that are currently manual-based (e.g. wagon inspection, braking test, braking sheet)

- Yard automation, especially in marshalling yards

- Digital Automatic Coupling (Type 5), in order to include from the start coupling and uncoupling function

- The implementation of ETCS Level 3 for higher capacity on rail.

Concerning the wagon fleet itself, an asset strategy for wagons (renewal and utilisation) must be established. The average age of an EU wagon fleet is between 30 and 35 years; on average, in the EU, a wagon is operational for approximately only 15 per cent of its lifetime. In parallel, it is also important to consider the digitalisation of rail freight, which is ongoing. The collection, storage, analysis and use of data have the potential to yield significant productivity gains for reliability, maintenance and asset optimisation; all are urgent first steps.

Culture challenges

To build this future, we need a strong mental shift – a new ‘innovation’ culture – based on return on investment (ROI), plus use-cases and Lean Startup approaches. At SNCF, we are fully convinced that the future of rail freight must not only be based on technological and medium- to long-term projects, with high investment costs, but we call for a better step-by-step approach, where demonstration of the first guides of digitalisation and the following steps are towards automation within less than 15 years.

The digital freight train at a glance: Innovation serving rail freight performance

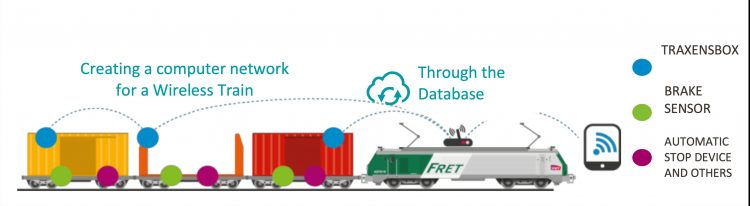

SNCF and Traxens have both invested over the last three years to explore the possibility of data and Internet of Things (IoT) advanced systems. With the help of Traxens technology, nowadays several rail freight undertakings – such as Fret SNCF, which has equipped 6,000 wagons – run digital freight trains that transmit data for a number of reasons, including:

- For shipping customers during the transport of their goods, as well as for fleet managers over longer periods, in order to improve the use of wagons within optimised logistics chains (geolocalisation, mileage, estimated time of arrival)

- For rail companies and wagon manufacturers to automate and speed up several operational processes, improve security and operate differently via remote-control (such as braking test)

- For shipping customers and asset managers, wagons equipped with devices bring additional new high-value traceability services, such as: the precise location of their wagons in real-time, at anytime and anywhere in Europe; alerts on arrival at strategic locations pre-defined throughout Europe, known as ‘geofencing’; and the recording of motion, stationary moments and parking times.

By allowing for the reinvention of rail freight and providing new services to its users, the digital freight train gives the sector the means to take its full place on the transport stage of the 21st century.

Built as a Solution-as-a-Service (SaaS), the Traxens solution is now an open solution accessible to every interested partner.

The Digital Freight Train project

Why was Traxens chosen by SNCF?

With its maritime experience with main shipping lines – such as CMA CGM, Maersk and MSC – Traxens’ shipping origin brings many advantages in terms of multimodality, economies of scale, similar technical challenges and multi-channel.

Why is this solution unique?

The Digital Freight Train is based on a revolutionary and technically unique IoT solution, making the train truly intelligent and with the capability to communicate.

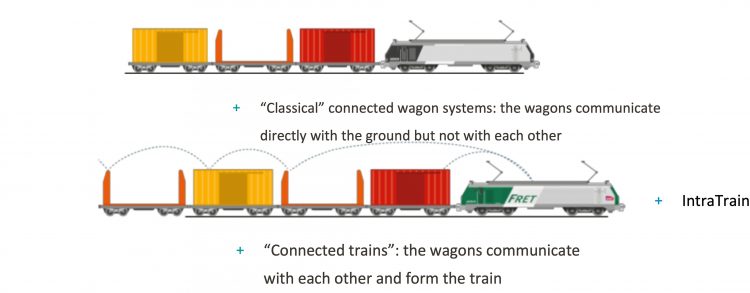

Thanks to the ‘IntraTrain’ communication system, the Digital Freight Train is known as a ‘connected train’ because wagons can communicate and interact with each other. The mesh network is a huge breaker in terms of innovation.

But, of course, challenges include the autonomy of energy and access to telecom networks.

It takes less than 30 minutes to convert a single wagon into an intelligent wagon, in a simple railway field (and not in workshop).

Figure 1 – The difference between the single ‘connected wagon’ and ‘connected train’ concepts.

Figure 2 – Breakdown of the ‘connected train’ solution.

A deployment approach: The example of the digital braking test

The braking test is a mandatory operation for railway safety. It is needed to check the train braking functioning before running and requires two people – a driver and a ground operator.

With the use of IoT, the principle is to perform the braking test digitally:

- Quicker: 25 minutes maximum, compared to 45 minutes normally

- Safer: Avoid the (up to) 800m walk along the trains for employees

- Easier: Using ‘plug and play’ sensors on the braking systems of the wagon.

In 2018, the French National State of Authority for Railway Safety (Etablissement Public de Fret Ferroviaire) gave its green light to operate trains with this digital operation. This is a total revolution in rail freight operations, and a first step towards automation.

To ensure interoperability: A necessity for rail freight

Because freight is international, it is important to ensure both technical and procedural interoperability.

Dealing with technical interoperability, this covers the transmission, availability and security of data, wherever it is in Europe. This results in having embedded systems capable of relying on complementary telecom or satellite networks, with the worry of data cyber-security (also valid for the cloud platforms).

It is necessary to ensure that the compatibility between wagons to connect the radio-based ‘IntraTrain’. Thus, in the future, it will be possible to perform automated operations – such as digital braking tests – on a freight train, regardless of the supplier of the devices that will manage the sensors of each wagon within the train (e.g. wagons equipped with the Traxens solution and others equipped of a solution from a different supplier).

Given that Fret SNCF’s rail freight operations are European, a single system approach at the EU level is mandatory.

Such an approach needs to be collaborative with all relevant stakeholders. The harmonisation should be considered following transparent and commonly agreed business cases (taking into account price competition with road transport and the situation of the single wagonload market segment), transparent selection processes and open standards.

Due to his experience in supply chains – rail and digital – Bertrand Minary oversees reinventing the rail freight business with added value, using Lean Startup, UX and Agile approaches. Bertrand has held multiple rail freight positions over 10 years: customer centre manager, sales and operations planning programme, and operations manager. He previously worked at Michelin as the Supply Chain Manager. Bertrand graduated in Transport and Logistics and he also teaches logistics and international transport in engineering schools. He was certified in July 2018 as a ‘Digital Transformation Facilitator’ by ESC Paris.

Issue

Related topics

Automatic Train Operation/Autonomous Train Control (ATO/ATC), Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, European Train Control System (ETCS), Internet of Things (IoT), Interoperability & Liberalisation, Multimodality, Operational Performance, Sustainability/Decarbonisation, Technology & Software, The Supply Chain

Related organisations

European Commission (EC), European Union (EU), French National State of Authority for Railway Safety (Etablissement Public de Fret Ferroviaire), Fret SNCF, SNCF, SNCF Logistics, Traxens