Big data analytics for asset management in Indian Railways

Posted: 18 May 2020 | Priya Agrawal | 3 comments

Priya Agrawal, Deputy Chief Signal and Telecom Engineer at Indian Railways, looks at the variety of opportunities which she believes India’s national railway should explore further in its mission to utilise big data analytics.

Credit: Jayasankar Madhavadas

Indian Railways is an organisation of such epic proportions that words such as ‘gigantic’ and ‘enormous’ seems inadequate. With route length of 95,981km, Indian Railway (IR) carried 1.2 billion tonnes of freight and 8.4 billion passengers during 2018-2019, making it the world’s largest passenger carrier and fourth largest freight carrier. What this also means, from an operational analytics standpoint, is a lot of data. However, Indian Railways currently lack abilities to use this data to derive accurate, contextual, and actionable insights for its business.

Applications of data analytics in railways

Data analytics technologies and techniques provide a means to analyse data sets and draw conclusions about them which help organisations make informed business decisions. Big data analytics is a form of advanced analytics, which involves complex applications with elements such as predictive models, statistical algorithms and what-if analysis powered by high-performance analytics systems.

Using connected IoT sensors, historic data and analytics, the data can be turned into useful information to improve asset utilisation and availability.

There is a whole range of opportunities which IR can explore in the area of big data analytics. Some of these applications include customer experience, train scheduling, timetabling, improving security at railway stations, automatic charting, network optimisation, crew management, inventory management, and IRCTC ticket management. The existing data from the passenger reservation system, operating control, CCTV cameras at stations, maintenance depots and stores, can be used intelligently to yield business benefits in the above areas. Current IT systems such as the real-time train information system (RTIS), the nation train enquiry system (NTES), and the control office application (COA) are some examples where data is being used to derive useful information.

One significant area where the use of data analytics is crucial is asset management. Asset management includes conducting an inventory of system assets, providing adequate staffing and training, performing preventative maintenance, and demonstrating adequate funding. In order to meet these requirements, an organisation must identify its needs and costs, and develop long-range financial plans. This is called asset management planning. It consists of developing a plan to reduce costs while increasing the efficiency and the reliability of the assets.

Asset management in Indian Railways

Asset maintenance is part of part of asset management and involves condition monitoring of different assets through IoT devices. Indian Railways is a custodian of significant asset base. Indian Railways asset base includes approximately:

- 121,407 track kms

- 34,319 route kms of electrified track

- 2,700 route kms of automatic signalling

- 12,000 locomotives

- 289,185 wagons

- 74,000 coaching stock

- 7,500 stations.

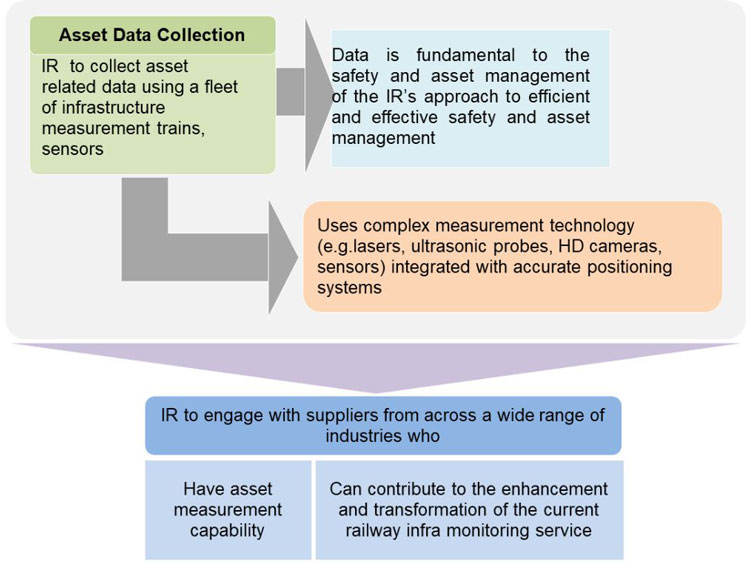

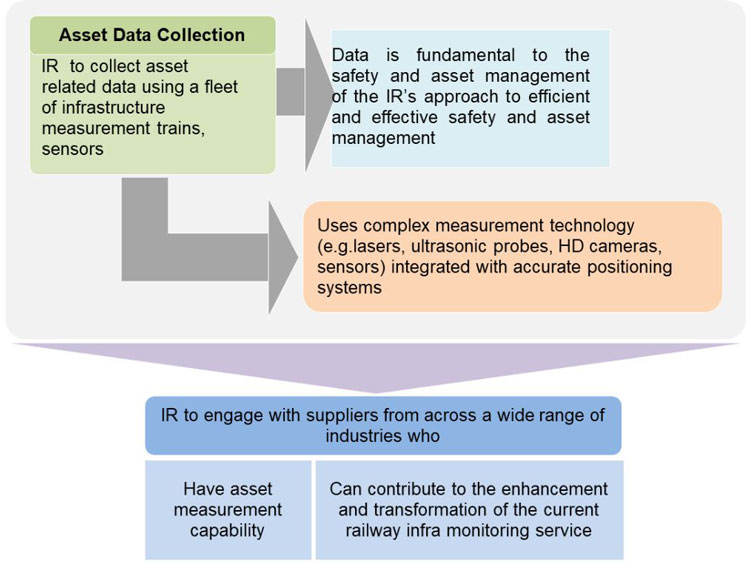

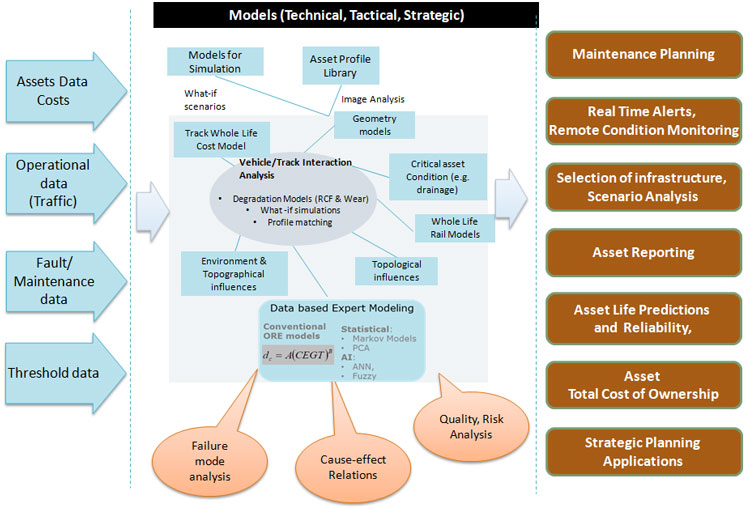

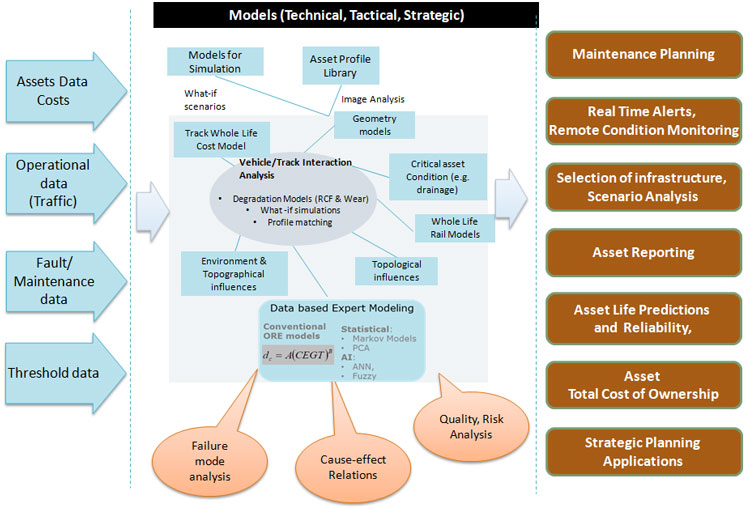

Indian Railways maintains huge terabytes of asset data. Using connected IoT sensors, historic data and analytics, the data can be turned into useful information to improve asset utilisation and availability. As of now, some efforts have been made to improve asset availability by adopting better maintenance strategies. These efforts have been made in departmental silos and lack a comprehensive approach. There is an opportunity to take a collective initiative to improve overall asset utilisation on Pan-India basis. Figure 1 illustrates the desired approach.

Figure 1

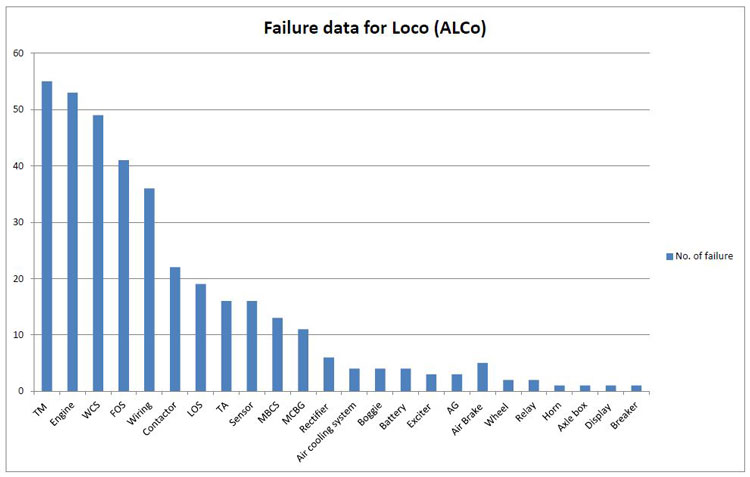

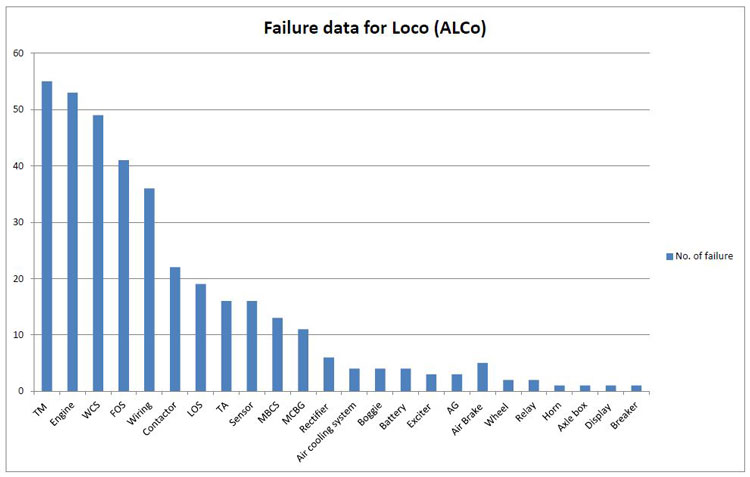

In the past, Indian Railways has collected asset data over 15-20 years and used them to re-define the periodic maintenance regimes. Because of the large volume of data and absence of data analytics tools, such decisions took a long time. To keep pace with increasing capacity requirements, it is important that technologies such as real-time sensors, data analytics should be used to facilitate decision-making processes and identify under-performing assets so that attention to those assets is given on a condition basis. For instance, the failure data of a locomotive (see Figure 2) illustrates that 70-80 per cent of failures are due to specific sub-systems. Often too much time is spent in maintaining those sub-systems which may not be the real cause of locomotive failures and inadequate time is spent in maintaining those sub-systems which are more prone to failure. It is important to reduce the down-time of frequently failing sub-systems through condition monitoring and predictive analysis techniques to reduce the overall downtime of locomotives. As per data, on date unscheduled attention of locomotives is as high as 62 per cent with respect to scheduled attentions. Such unscheduled maintenance visits can be avoided using adequate predictive maintenance systems.

Figure 2: Source – case study IR diesel loco sheds.

Existing condition monitoring and data collection systems in IR

1. Signalling systems

Through data loggers, the health of gears such as track circuits, point machines, axle counters and other internal circuits, is monitored and SMS are generated for various fault alerts. Furthermore, out of 7,500 stations, more than 5,500 stations have been equipped with Wi-Fi facilities. Though the capabilities exist, they are not utilised to the full extent. It is required that a more rigorous approach should be adopted to collect all kinds of asset data through sophisticated sensors and modern data analytics techniques be used to reduce maintenance requirements.

2. Rolling Stock

Indian Railways is envisaging converting its ‘freight examination yards’ into technology-driven ‘Smart Yards’ for automatic detection of faults/defects/deficiencies in freight wagons.

Indian Railways is envisaging converting its ‘freight examination yards’ into technology-driven ‘Smart Yards’ for automatic detection of faults/defects/deficiencies in freight wagons. The automatic defect detection equipment of a Smart Yard shall provide advance data about hot axles and wheels, wheel flats, wheel profiles and diameter, load imbalance, loose and hanging parts, etc. even before the rake arrives at the maintenance yard. It will then use this information for objective fault assessment and proactive staffing, thereby, reducing turn-around time while boosting safety and improving productivity. Initially, 40 yards have been identified for conversion to Smart Yards in phase 1. However, different sub systems are provided by different suppliers and data integration is challenge.

3. Locomotives

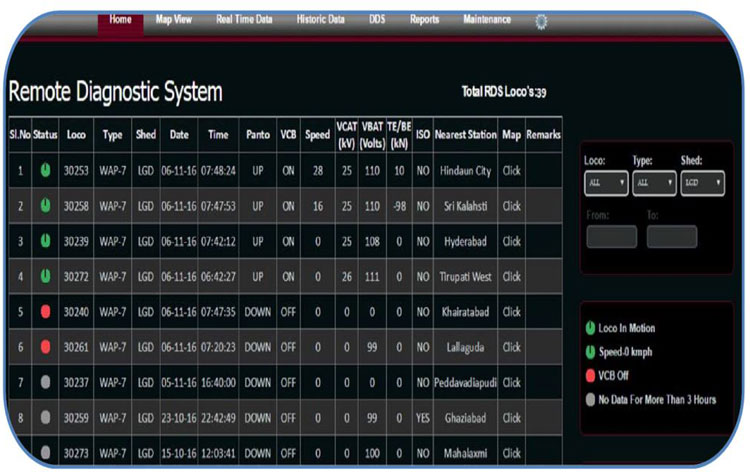

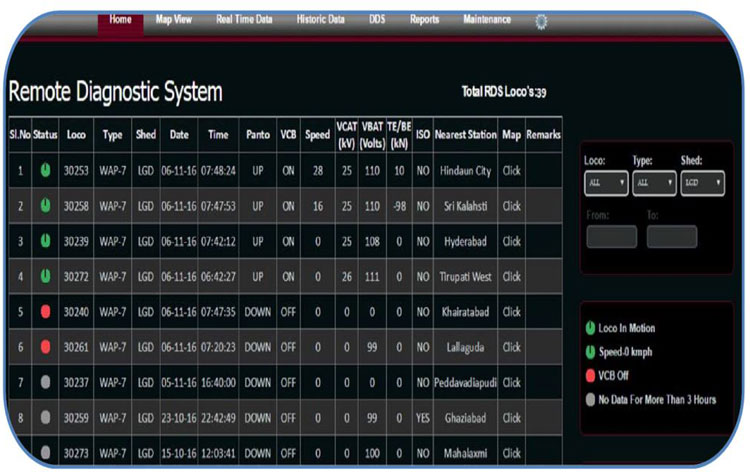

REMMLOT enables health monitoring as well as fleet management of locomotives. The system monitors various operating parameters to achieve fuel saving and helps in analysis in case of untoward incidences. Presently, 18 types of health alerts in the form of SMS are generated. Electric locomotives have developed a remote diagnostic system (RDS). This GPS-based system monitors the current location of a locomotive and generates SMS-based alerts to maintenance staff with respect to isolation of key sub-systems, see Figure 3. The system also has the capability to monitor traction motor voltage, status of auxiliary machines like compressor, traction motor blower, etc. However, the existing system generates alarms only on isolation.

Figure 3

4. Over-head equipment (OHE)

Oliver ‘G’ is an over-head line inspection system with video recording and GPS tracking for improving the reliability of OHE. However, mostly manual inspections of OHE are done and various parameters are measured at regular interval unless there is any change in track parameters or there has been any OHE modification work.

5. Track

The existing system for monitoring the health of the track includes OMS Car, TRC Run, Oscillograph Car and other field inspections. Indian Railways is working towards introduction of an Integrated Track Monitoring System that shall consist of:

- Track parameters recording system

- Full rail profile and wear measurement system

- Rear Window Video Recording of track

- Video recording of track components and analysis by image processing for status of track components

- Other Transducers/Sensors.

Though several systems have been installed for data collection and condition monitoring for different assets, the analytics capacity of these systems is very limited. Furthermore, all these data collection systems work in technical silos, each with its own acronym, making it difficult to integrate data to acquire useful information.

Figure 4

Creating a data-driven railway

Figure 4 gives an overview of the required capabilities for a comprehensive asset information system. A lot of work is required to be carried out in the area of data collection, data management and data service provision, so that the benefits of data analytics can be reaped for improved asset reliability. Some pointers are:

- The creation of a supplier ecosystem with IoT-based capability

- Data collection across all asset types and provision of new data collection equipment and platforms

- The opportunity for managed services through a single service integrator

- Integration of asset data, operation data, asset data and maintenance using adequate interfaces

- Easy mechanism to exchange asset data throughout the lifecycle of assets

- Decision modelling and risk analysis tools to identify bottlenecks

- Raise maintenance alerts for different assets to enable safe, efficient and effective delivery of the operational railway

- Strategic maintenance planning and creation of reports for easy accessibility of asset information.

- Distribution of tablets to field maintainers and direct access to asset data and maintenance requests from central system through existing Wi-Fi facility, thus removing paperwork.

Indian Railways must absorb these huge banks of data and capture them in a national intelligence model; one that can serve this data-driven railway in a cohesive, safe and cost-effective manner.

OUT NOW: The Definitive Guide to Rail’s Digital Future

The rail industry is undergoing a digital revolution, and you need to be ready. We have released our latest market report, “Track Insight: Digitalisation.”

This is not just another report; it’s your comprehensive guide to understanding and leveraging the profound technological shifts reshaping our industry. We move beyond the buzzwords to show you the tangible realities of AI, IoT, and advanced data analytics in rail.

Discover how to:

- Optimise operations and maintenance with real-time insights.

- Enhance passenger services through seamless, high-speed connectivity.

- Leverage technologies like LEO satellites to improve safety and efficiency.

Featuring expert analysis from leaders at Nomad Digital, Lucchini RS, Bentley Systems and more, this is a must-read for any rail professional.

Related topics

Big Data, Digitalisation, Internet of Things (IoT), Operational Performance, Passenger Experience/Satisfaction, Technology & Software, Track/Infrastructure Maintenance & Engineering

Very interesting, Thanks for sharing.

Priya, interesting read, and thank you.

We’re speaking with several Rail/Fleet companies about using predictive analytics to maximise fleet up-time.

https://www.linkedin.com/pulse/5-reasons-why-rail-companies-using-predictive-fleet-blackstock-/

Mam, I have a very genuine query that India has successfully used double-stack freight trains in Phulera- Jaipur section. Why IR is not using double-decker trains? They must change the wiring and should increase the height of the boogie for sustainable development. In the USA, Australia, and many other countries are using double-decker trains. India has such a large population and many we have so many waiting list passengers who can not do their journey comfortably. IR should use well-manufactured trains not the trains which is not at all good. India is using the worst quality of double-decker trains. They must look into the issue of double-decker trains (a good one). First, they must change the wiring in the route to increase the height.