How EU-RAIL prepares for DAC: specification, design, testing and pioneering

Posted: 25 April 2025 | | No comments yet

Today, rail freight largely operates the same way as in the early days, it heavily relies on manual interventions at each step, including (un-)coupling, and does not allow only very limited data connectivity. Karel van Gils from EU-RAIL explains further…

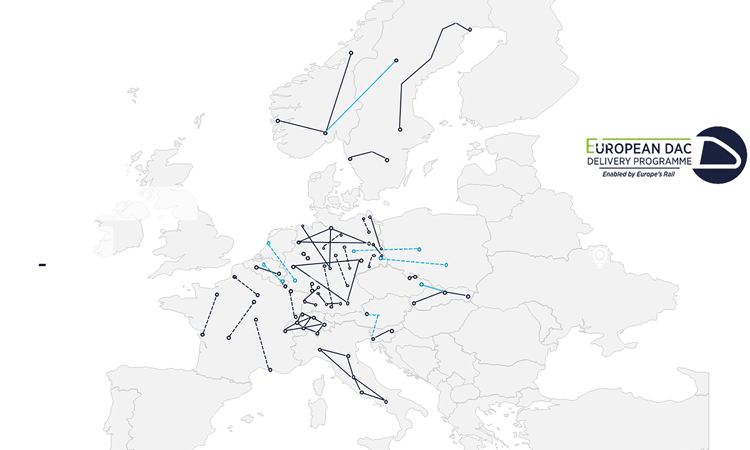

Broad Expression of Interest in Pioneer DAC Trains, June 2024. c: EU-RAIL

This outdated system severely hinders rail freight’s potential to enter the digital age, dramatically increase its efficiency and affects its potential to offer more sustainable freight logistic services in Europe.

The European rail sector, through Europe’s Rail Joint Undertaking (EU-RAIL), is focused on driving automation and digitalisation in rail freight, primarily through the implementation of Digital Automatic Coupling (DAC) as enabler. This modernisation effort is expected to boost capacity and contribute to modal shifts to rail and thereby help to meet emission reduction targets, contribute to Europe’s re-industrialisation, and improve working conditions for the rail freight workforce.

To achieve these goals, the EU-RAIL enabled the creation of the European DAC Delivery Programme (EDDP) in 2020, a group open to all the rail sector beyond the EU-Rail membership. Under its umbrella, multiple projects aim to design, test and deploy this technology across Europe.

Given the international scope of rail transport, a standardised European approach is essential.

Given the international scope of rail transport, a standardised European approach is essential. This ambitious effort must address both new and current fleet, consisting of about more than 30,000 locomotives and over 500,000 freight wagons, many of which are decades old.

Establishing specifications and testing

As part of its innovation efforts, EU-RAIL set up Flagship Project 5 (FP5) TRANS4M-R, which focuses on developing requirements, functional and system designs for wagons, locomotives and trains. In close cooperation with the supply industry, standard assets and processes are also being developed. The project conducts laboratory tests and uses demonstrator trains to validate all assumptions made at early engineering phases.

In addition to the Flagship Project, EU-RAIL has issued other open calls for proposals resulting in projects for analysing and specifying system components, such as the DACFIT and EU-RAIL call 2024. By the end of 2024, EU-RAIL plans to release an open call for tender for engineering activities on (shunting) locomotives to be equipped with DAC systems, including couplers, energy supplies and data systems.

Technical progress and approach

The rail freight sector is facing a multitude of challenges such as issues related to network capacity, reliability and productivity. Manual processes still entail risks for workers. Rail has the opportunity to adopt the emerging digital technologies to better meet the customer needs. FP5-TRANS4M-R brings together 76 partners from end users, large industry, railway undertakings – operators and wagon keepers, SMEs, academia, and research, committed to deliver an increase of the modal share of rail freight by 30% in 2030.

FP5-TRANS4M-R’s overall goal is to establish rail freight as the backbone of the lowest emission and most resilient logistics chain in Europe fulfilling the end customer requirements. Two technology clusters, one on Full Digital Freight Train Operation (FDFTO) and the other on Seamless Freight Operation, will develop, validate and demonstrate the FP5-TRANS4M-R technologies following an integrated systemic approach.

Next to the Digital Automated Coupler (DAC), which acts as a key technical enabler, a strong emphasis is placed on rail freight and intermodal transport services to deliver green freight.

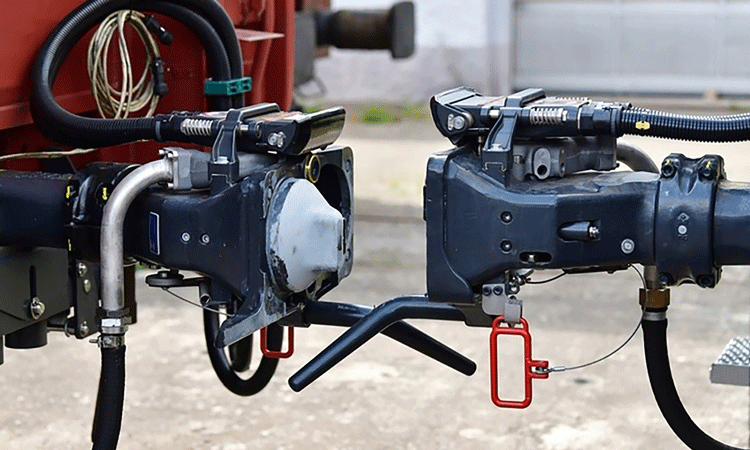

The project uses digitalisation and automation applied to the operational functions and processes, including those linked with other transport modes, facilitating the establishment of a framework for data exchange. FP5-TRANS4M-R research actions aim to deliver innovative interoperable and scalable solutions. Next to the Digital Automated Coupler (DAC), which acts as a key technical enabler, a strong emphasis is placed on rail freight and intermodal transport services to deliver green freight. The full potential of automation and digitalisation of DAC is integrated in the logistics value chain within the project activities. An initial fully digital freight train with DAC, including energy and data supply, hybrid couplers and automated brake tests has been developed.

Initial solutions have been tested and results made available in Sounding Boards to raise awareness and gather feedback from diverse stakeholders, including operators, infrastructure managers and policymakers. Trials have initially focused on mechanical requirements and TSI compliance, and they are now made to showcase the new digital possibilities, so called train functions such as displaying wagon and train statuses and enabling automatic coupling and remote (un-)coupling. These innovations were demonstrated at InnoTrans 2024.

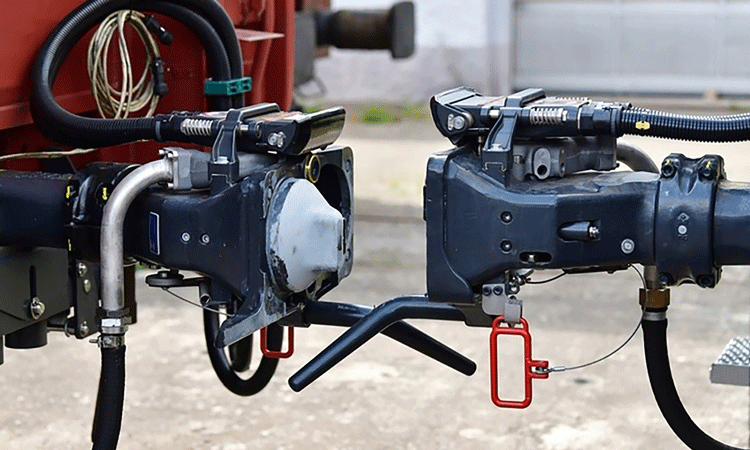

Digital automatic coupler and e-coupler.

c: EU-RAIL

Connecting with other railway transformation programmes

In EU-RAIL’s Unit System Pillar Task 4, the interaction with other railway transformations – such as ERTMS, ATO, and soon FRMCS – is managed. Technical coordination on issues like train length and integrity is done alongside CCS System Pillar Task 2, to ensure future capabilities, including moving block functionality, for greater capacity and access to new functionalities.

While FP5-TRANS4M-R focuses on developing wagon and locomotive functionalities, the EU-RAIL System Pillar handles train-landside connectivity. This includes upgrading vehicle software, integrating with shunting yard management systems, and ensuring compatibility between various software versions. The aim is to initiate these features in the upcoming years through a step-by-step approach.

EU-RAIL, working closely with operators, is translating the overarching process architecture into operational guidelines for ground staff, drivers and operators. With the European Union Agency for Railways (ERA) and the rulebook activities in System Pillar (Task 2, on CCS functionalities), a European-harmonised system is being developed. This iterative process, while specs and technical solutions are still being finalised, requires close cooperation and transparency among stakeholders, facilitating the system’s acceptance and adoption.

Preparing for deployment

The DAC development is a major transition for the railway sector. To ensure readiness for commercial use in Europe, EU-RAIL has established the open European DAC Delivery Programme (EDDP), which explores scenarios, transition scopes and financial analyses. This initiative will provide the necessary information for future implementation decisions.

Through a coordinated governance structure, the rail freight sector representatives participating to the fully open EDDP have already endorsed decisions regarding a new coupler, electric coupler for power and data connection, and associated processes. Further decisions on the architecture and design of energy and data systems are expected during the course of the programme. As the design and research phases are already largely advanced, an initiative launched under the umbrella of the EDDP plans to start operation on certain commercial routes in Pioneer Trains with a basic and approved package. This basic package is designed in a way to allow additional functionalities to be introduced gradually as technology advances.

Following a transparent call for interested companies, many operators, industry leaders, leasing companies, infrastructure managers and clients have expressed their commitment to this pioneering project. In September, the European Commission published a call under the Connecting Europe Facility inviting stakeholders to apply for EU funds for the DAC, including for the validation of the system in commercial operations in the context of the Pioneer Trains.

Reaching technical consensus

From a railway perspective, this new system is steadily progressing. With rail sector and the European Commission support, EU-RAIL enabled the start of planning for the take up of the DAC technology with the creation of the European DAC Delivery Programme in 2020, open to all interested parties. Now, the rail sector is reaching technical consensus on the coupler interfaces specifications, on harmonised processes, and started initial laboratory and field tests. Demonstrator trains are operating across Europe, and numerous conferences and events have helped to showcase the DAC potential and capability for a more performant rail freight, addressing at the same time the sectorial and European challenges to be met before entering a sustainable deployment.

Heading toward Pioneer DAC Trains in 2027, the sector will assess the viability and feasibility of DAC in the rail freight industry.

For now, we’re focused on a successful technical conclusion phase and upcoming Pioneer DAC Trains, moving from discussion to testing and implementation.

For now, we’re focused on a successful technical conclusion phase and upcoming Pioneer DAC Trains, moving from discussion to testing and implementation. It’s time to consider if the 180 year old screw coupler is not hindering rail freight to really support the green and digital transition, essential for rail freight to fulfil its role in Europe’s sustainability and industrial growth ambitions.

EU-RAIL is paving the way for new possibilities in the rail freight sector, built on a solid process, proven technology and close collaboration with the whole sector, including railway operators, infrastructure managers, supply industry, ERA & NSA’s, leasing companies and policymakers.

For further information, please join the EDDP and Sounding Boards, where programme updates and exchanges are made with the entire sector. For more details, please also visit the EU-RAIL website.

c: EU-RAIL

In 1991, Karel van Gils joined the railway sector and worked for Dutch Railways (NS) in operations, maintenance and commercial positions in Germany, the UK, and the Netherlands. Before moving to ProRail, Karel worked as a Director of Engineering for the public transport company (GVB) in Amsterdam. In 2019, after two years serving as Director of Asset Management at ProRail, Karel was appointed Director of Innovation. Since September 2023, Karel works for EU-RAIL in Brussels.

Issue

Related topics

Big Data, Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Freight, Interoperability & Liberalisation, Operational Performance, Regulation & Legislation, Rolling Stock Components (Interior/Exterior), Safety, Sustainability/Decarbonisation, Technology & Software, The Workforce