Next generation network management

Posted: 11 November 2024 | Patrick Mehringer | No comments yet

As the mobility sector plays a major role in countries reaching their sustainability targets, one key approach to reducing CO2 emissions is shifting passenger and freight transport from road to rail. The integration of various systems in the railway industry through digitalisation is seen as crucial in this process, while also helping to improve efficiency and profitability. Patrick Mehringer, Fleet Manager at Siemens, explains more.

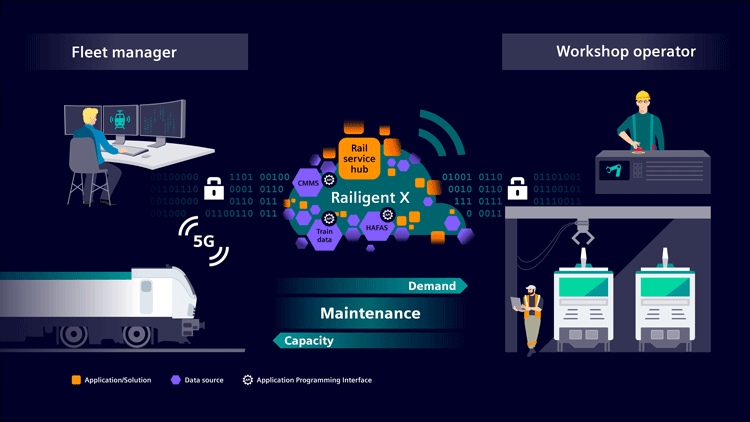

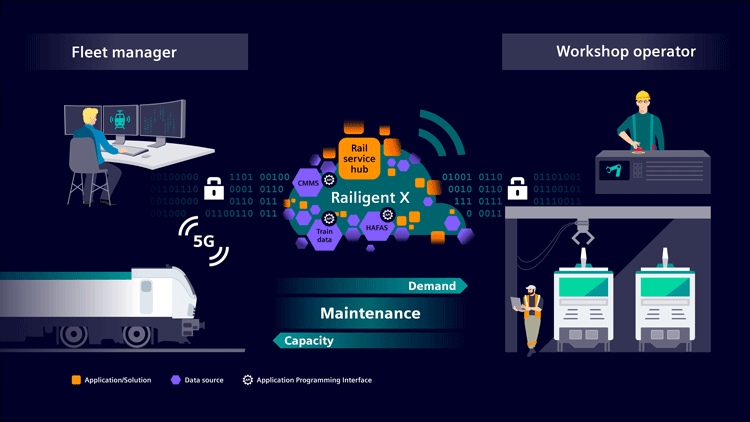

The Rail service hub is a digital solution aimed at enhancing rail network management efficiency. It simplifies maintenance planning and execution by providing real-time fleet information, while coordinating with workshops to improve overall railway maintenance processes. The Rail service hub is part of Railigent X, Siemens Mobility’s cloud-based application suite, which utilises IoT and AI to connect and optimise railway data, enhance system availability and reduce downtime.

Harnessing digitalisation for rail

The rail industry is characterised by a large number of suppliers of rolling stock, infrastructure and services at national and local level, often with different systems operating in parallel. Connecting all these systems and stakeholders on a digital platform is a critical step to efficiently digitalising rail operations. When implemented intelligently, it can lead to significantly higher profitability and efficiency.

Based on Railigent X, Rail service hub connects vehicles and workshops smartly. Benefits include increased efficiency in maintenance management. c: Siemens

Digital services delivered via the cloud can even further enhance these benefits, e.g. by intelligently linking all available data from rail systems and preparing them in a way that makes them easy to interpret and act on. So, railways, system operators and maintenance personnel can analyse and make the best use of their data to increase rail system availability and reduce downtimes.

One example would be the remote control of train IT systems from the operations control centre. Another is fully digital workflows for fleet and maintenance management, such as Siemens Mobility’s Rail service hub.

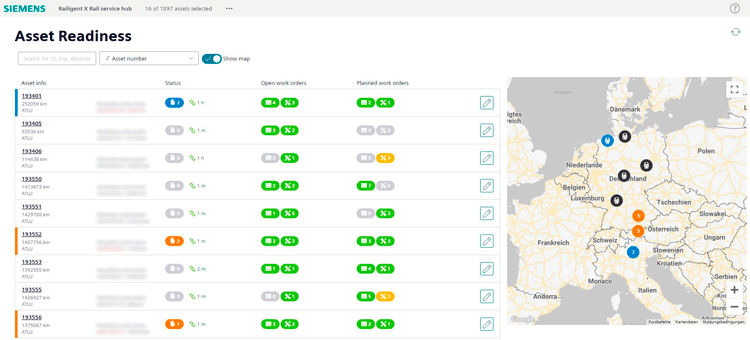

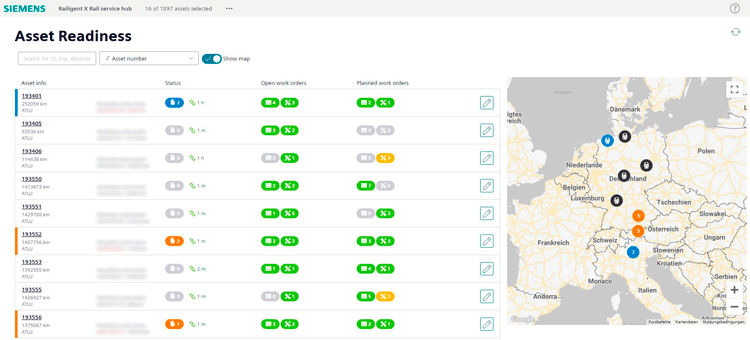

Fleet Asset Readiness helps fleet managers visualise the condition of the fleet and identify maintenance needs. c: Siemens

Optimising maintenance

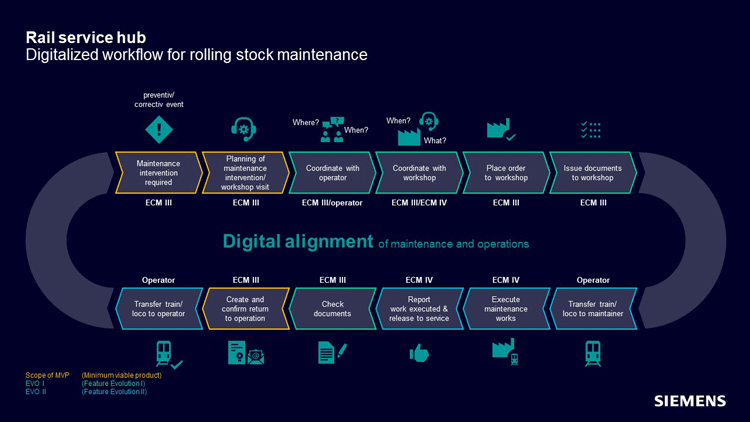

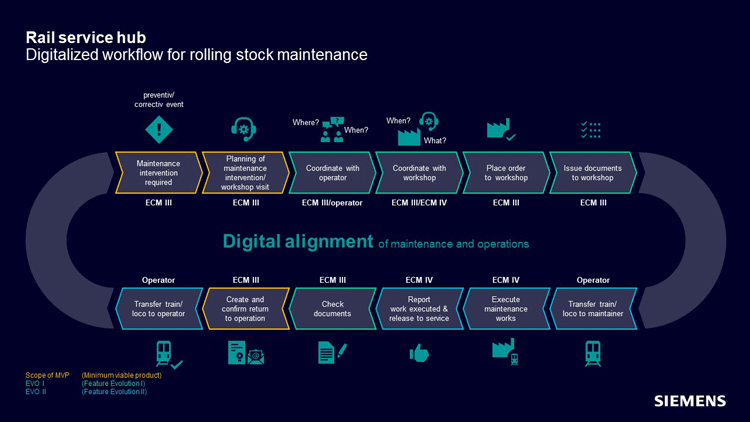

Entity in Charge of Maintenance (ECM) is a role in European rail transport responsible for the mandatory maintenance of rail vehicles, categorised into different levels. In accordance with these roles, the Rail service hub aims to simplify the planning and execution of maintenance measures for fleet managers (ECM III) and workshop operators (ECM IV).

It does this by managing all relevant fleet information in real time, including current operating status, GPS position of individual vehicles or even components, any restrictions and open work orders. At the same time, it displays the available maintenance capacity of the digitally-connected workshops. Information about the work to be done is automatically compared with the available capacity of the shops.

For users, the current focus is on two applications: Fleet Asset Readiness and Workshop Finder. Fleet Asset Readiness helps fleet managers visualise the condition of their vehicles and identify current and future maintenance needs. The application coordinates the necessary maintenance activities with the services offered by the respective workshop.

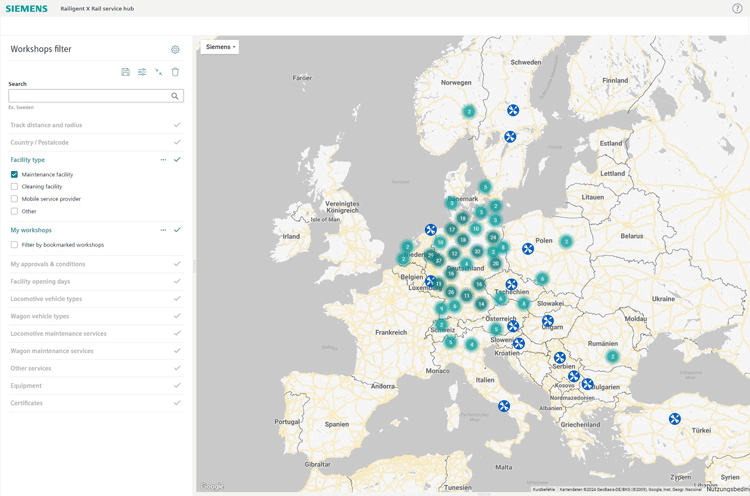

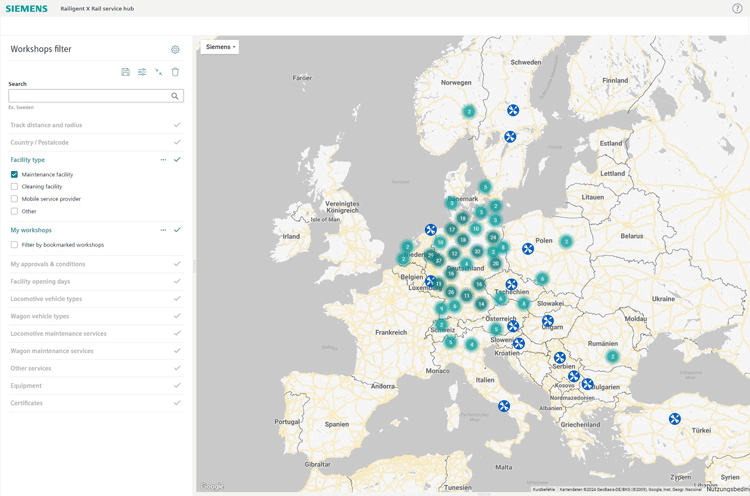

The Workshop Finder application is a useful tool for both fleet managers and workshop operators. It coordinates, manages and documents maintenance work and suggests suitable workshops based on criteria such as location, performance or equipment.

Using these Rail service hub applications, vehicles can be routed directly to the nearest workshop for optimal maintenance. Necessary documents, such as digital work orders, are automatically sent to the workshop. Once maintenance is completed, fleet managers receive documentation of all work performed. Plus, the next time the vehicle needs to be serviced or repaired, partner and third-party workshops have access to a complete, data-based overview of the vehicle.

Workshop Finder supports fleet managers and workshop operators in coordinating, managing and carrying out maintenance work. c: Siemens

Connecting the dots: a network of workshops

The European network of locomotive workshops consists of approximately 650 locations in more than 30 countries, including partner and third-party locations. These shops are often located at major transportation hubs such as international rail corridors, ports and freight terminals. Locomotive workshops within the European network benefit from being connected to the Rail service hub. They can specify which services they offer and whether they currently have capacity to take on orders.

The Rail service hub was developed and validated with maintenance experts as an internal Siemens application, but is now offered to external users as Software-as-a-Service. It benefits vehicle owners, rail operators and the ECM function, but it is equally beneficial to workshops. Since the Rail service hub is a modular solution, it allows users to access specific service levels according to their needs.

Needless to say, the Rail service hub meets stringent data privacy and cyber-security requirements, comprehensively protecting sensitive vehicle and operational data. Holistic solutions are used to address risks during operations and throughout the entire lifecycle of rail systems. This comprehensive security enables the full potential of digital transformation.

The Rail service hub is based on a fully digitalised work process that combines and dynamically manages data from multiple systems in real time. c: Siemens

Looking ahead

The current functionality of the Rail service hub marks the starting point for further developments. In the future, it will also integrate additional interfaces and systems from other workshops and rail operators. This will allow potential customers to connect their own digital environment (CMMS system) to the Rail service hub and seamlessly perform the planning process. Supplemental data will enrich the process, e.g. with information on fleet, workshop or maintenance order status.

Fleet Management (ECM III), Siemens Mobility Rail Services. [email protected]