CAF MiiRA’s cutting-edge solutions on lightweight gearboxes

Posted: 6 June 2022 | CAF MiiRA | No comments yet

CAF MiiRA presents its new generation of light and efficient gearboxes that contribute to zero emissions, keeping the current reliability and quality standards.

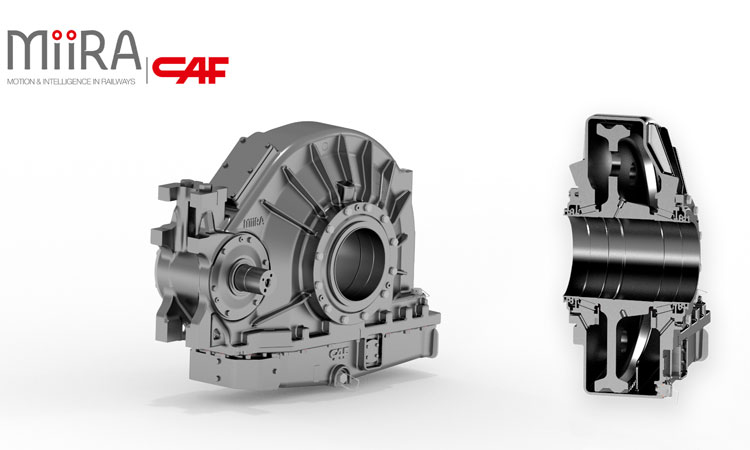

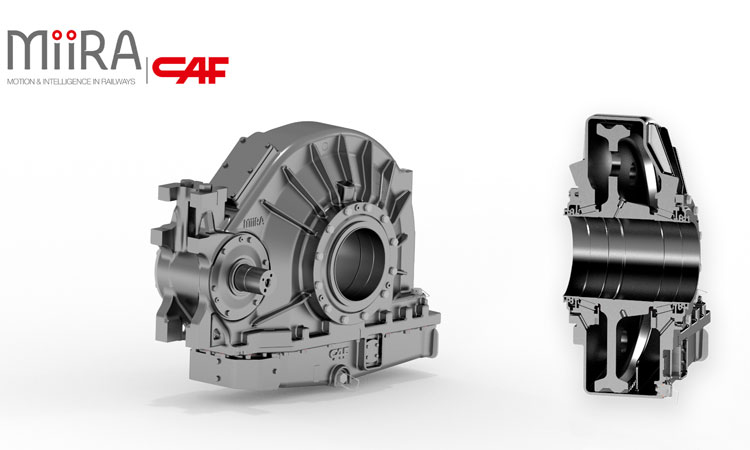

CAF MiiRA lightweight single stage gearbox solution for metro

CAF MiiRA IS dedicated to the design and supply of complete wheelsets for different vehicle types and platforms. The company’s experience in the design and assembly of gearboxes has been continuously growing in this market, offering high quality, reliable and cost-competitive solutions. This has been possible thanks to significant investment in research and product development, together with a highly qualified expert team. To maintain its current market presence and continue a sustainable growth path that fosters its consolidation as a referent in railway transmission systems, the company aims to provide solutions to the most relevant sectorial challenges. Zero emissions is a key trend in the sector, and CAF MiiRA is reinforcing its investment in research and innovation. This has brought a deeper knowledge in state-of-the-art key technologies and design methodologies, that play a significant role in reaching this objective, contributing to an improvement in the weight and efficiency of its solutions.

The gears have been weight-optimised with new web designs, together with holes that allow for significant weight reduction, while keeping the stiffness of the part, to prevent gear teeth misalignment problems.

As a result, CAF MiiRA presents its new generation of light and efficient gearboxes that will contribute to zero emissions, keeping the current reliability and quality standards. This is achieved by lowering energy consumption rates thanks to weight optimisation and more efficient design solutions. The new products allow for better integration in different bogie configurations, thanks to more compact designs.

Special focus has been given to the heavier gearbox elements, namely housing and gears, where special lightweight housings, provided with weight-optimised fixation supports to the bogie connection elements, have been designed. Housing has been redesigned, fostering weight reduction while keeping the stiffness and thus, the frequencies of the most critical modal shapes that induce noise. The thickness of specific housing areas, not critical in terms of structural integrity, have also been redefined. Restrictions and limitations of the manufacturing process have been considered, to prevent future production problems.

The gears have been weight-optimised with new web designs, together with holes that allow for significant weight reduction, while keeping the stiffness of the part, to prevent gear teeth misalignment problems. The gear micro geometry has also been optimised to minimise noise, as well as gain in reliability and maintaining the efficiency values.

The width of the gearbox assemblies has been reduced, achieving more compact designs that minimise weight and improve the oil volume distribution, enabling its use for the most restrictive bogie configurations.

These two elements have not been the only object of study, but also bogie connection elements and secondary ones, with lighter versions, keeping their robustness and safety standard levels.

The use of FEM and additional advanced modelling techniques has been relevant in this study, however, its combination with a significant effort in the dimensioning and component selection field has been determinant. For this, collaboration with key partners has contributed to more accurate improved calculation models that enable weight reduction and more efficient designs.

Efficiency in the lubrication circuits has been addressed, assuring the correct distribution of the oil to the critical surfaces, while the volume of lubricant may be minimised, if required, resulting in more compact solutions.

CAF MiiRA has harnessed service data for a better understanding of operational conditions and demands, allowing continuous product improvement, resulting in more reliable, lighter, and efficient solutions.

CAF MiiRA has harnessed service data for a better understanding of operational conditions and demands, allowing continuous product improvement, resulting in more reliable, lighter, and efficient solutions.

Overall, the experience acquired thanks to these research activities, allowing the company to not only offer improved solutions in the short-term, but also gain a deeper understanding of its components and associated technologies, establishing a continuous improvement path for the coming years, thanks to the progressive digitalisation of rolling stock assets.

CAF MiiRA’s future research activities will be intensified, offering integral solutions to customers that contribute to increased system reliability and resilience, increasing the competitiveness of the railway system over alternate transport modes, and keeping zero emissions as a key driver.

For more information, visit: cafmiira.com.

Issue

Related topics

Bogies & Wheelsets, Rolling Stock Components (Interior/Exterior)