Designing out the noise: Optimising track design for a quieter railway

By Lucie Anderton, Pınar Yılmazer

5 April 2022

Shares

The LOWNOISEPAD project brings together 12 European railway infrastructure companies to find an optimal rail pad for both noise and track quality issues. The results are hoped to play a part in improving the quality of life for those living close to railway networks. Colleagues Pınar Yılmazer and Lucie Anderton from the UIC’s Sustainability Unit, explain more.

To support a green recovery, railways must contribute to healthy, sustainable lifestyles and economies; an important part of that is to strive to be good neighbours to those living around the tracks. Railways must rise to the challenge of the ambitious targets set in the European Zero Pollution Action Plan and contribute to reduce the share of people chronically disturbed by transport noise by 30 per cent.

European railways have successfully focused on the effective management, monitoring and maintaining of infrastructure and rolling stock to reduce railway noise and vibration by being involved in several collaborative research and development projects. The dominant source of noise from the railways is the radiated noise from the rail and the wheel interface. While the extensive construction of noise barriers has effectively reduced noise pollution, particularly in urban areas, seeking solutions to reduce noise at its source is the most efficient approach and the main area of focus for the International Union of Railways (UIC) and its members.

The UIC, together with its members, seek collaborative approaches to share a global vision of being a good neighbour. The UIC Noise and Vibration (NV) sector is a working body which is helping to make tangible progress towards a better understanding of noise-generating mechanisms in railways and quieter operations.

The UIC’s latest noise report, Railway Noise in Europe, State-of-the-art report, highlights how noise levels on European railways have been significantly reduced through innovative solutions, including the retrofitting of cast- iron block brakes on freight wagons with composite brake blocks. The UIC report provides the most promising measures, as well as the most cost-effective strategies, capable of delivering significant reduction in complaints due to environmental noise. The making of the report has spurred the UIC working group on to further improve the performance of methods for noise prediction, control, and assessment with more innovative, cost-effective solutions and methodologies, with a focus on the optimisation of the whole system of vehicle, wheel and rail and their interactions.

LOWNOISEPAD: European joint research on optimising rail pads

One of the most interesting opportunities to reduce noise pollution at source is with rail pads. The rail pads contribute to the reduction of sound radiation from the track as it vibrates while a train runs over it. However, the difficulty with rail pad design is the trade-off that exists between noise reduction and better track quality. It is this challenge that has sparked the latest UIC research project.

Testing in Austria to find an optimal rail pad for both noise and track quality issues. Credit: ÖBB Infrastruktur AG

As stated in the Railway Noise and Vibration book, ‘the stiffness of a rail pad is generally defined in terms of its static or low-frequency dynamic behaviour over large strains’ [Thompson, Railway noise and vibration: mechanisms, modelling and means of control, Elsevier Ltd, 2009.] and is selected in the technical specifications considering the objectives of the track engineers to ensure operational safety and reduce maintenance costs. The design of a rail pad is always a compromise between the requirements from track engineering and acoustic engineering. Softer rail pads help to better distribute the load; therefore, it helps to have the long-term stability on the ballasted track. [Auer, “Zur Verschleißreduktion von Gleisen in engen Bögen,” 2010.]

On the other side, stiff rail pads with low track decay rates (TDR) help to reduce the noise emissions [Squicciarini, D. Thompson, M. Toward and R. Cottrell, “The effect of temperature on railway rolling noise,” Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit Institution of Mechanical Engineers, vol. 230, no. 8, pp. 1777-1789, 2015.][Oregui, A. Nunez, R. Dollevoet and Z. Li, ‘Sensitivity analysis of railpad parameters on vertical railway track dynamics’, ASCE Journal of Engineering Mechanics, vol. 143.]

When aiming to minimise the radiated noise from a track, there is a significant conflict of targets that must be considered by track engineers and acousticians. Therefore, the target of this project is that an acoustically optimised rail pad can cope with these two scientifically proven demands simultaneously at the same time and lower the noise significantly without demanding high-cost mitigation measures.

Acoustic stiffness and the damping characteristics of rail pads are considered together, along with the increased awareness of environmental responsibility and interest in the effects of transport noise on human health and possible noise reduction in railways.

For the last year, the UIC has been working with its members to better understand the noise-generating mechanisms to make tangible progress towards a being a better neighbour. The Low-Cost Noise Control by Optimised Rail Pad (LOWNOISEPAD) project brings together the European railway community to find an optimal rail pad for both noise and track quality issues and for the different situations encountered in 12 European railway networks.

Cutting edge collaborative research

This project, planned to be completed by the end of 2022, has real-life operational 100m test sections in the networks of the project partners. The test lines are being monitored with state-of-the-art technology to obtain noise data for analysis, all made possible through this collaborative effort.

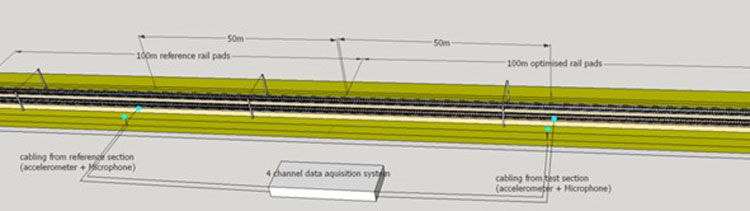

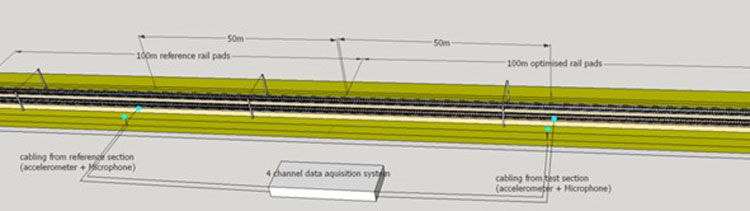

The approach is the result of 12 UIC members working together in collaborative knowledge sharing. Participants shared information about their existing rail pads and assets such as fastening systems; together the participants selected a reference and a test pad to measure and compare during the project process. Obtaining a detailed understanding of existing standard rail pads, their typical low TDR values, the static/dynamic stiffness data and their distribution over the entire network is critical for the project. Each member has defined two adjacent 100m test sections in their network and has planned to prepare these test sections to be equipped with reference and test pads in 2022.

Important factors that influence rail noise have been considered, and test sections with the same track components (e.g., rail fastening system) and the same acoustic rail roughness will be used for the measurement campaign.

In most cases at speeds between 80-160km/h, the rail is identified as the dominant source in the 800Hz to 2kHz frequency band [Verhelst and E. Heylen, “Development, validation and roll out of noise reducing rail pads on the Belgian INFRABEL railway network,” in IWRN13, Ghent, Belgium, 2019.]

The longitudinal resistance of the rails is related to the interaction between the components affected by the dynamic forces transmitted from rails to the sleepers in the longitudinal direction. The interaction with fastening systems and rail pads placed between the track and sleepers is important to reduce the noise radiation from the rail. An ideal rail pad should not be too stiff, to enable flexibility in the track as required by track specifications (to prevent damage to the track), but this increases rail vibration and thus noise radiation. For this reason, the same train types will run on these test sections, one serving as a reference and the other being used to test the selected pad (with a significant TDR difference). In the meantime, vertical rail acceleration and noise emission will be acquired simultaneously at a distance of 7.5m from the track centre line and a height of 1.2m above the rail (point ‘A’ of ISO3095) as indicated in Figure 1.

Figure 1: Measurement set-up at the 12 European railways.

Field tests start in 12 European countries

Until the first half of 2022, each participant will carry out the measurement campaign individually in their own networks by applying the same test method determined, including TDR (compliant with EN 15461) and pass-by (compliant with ISO 3095) on the test line they have prepared. The fleet type (i.e., passenger, freight, model) and operating speeds will also be determined by the project participant.

The project uses the data collected from the field measurement rather than any computer‑based modelling. All data will be transferred to the software tool developed within the scope of the project and evaluated. The software tool will also be used to estimate and analyse differences in possible noise emission values that would occur by changing the TDR for the standard track specification, type of fleet operated and the operating speeds in the members’ network. A correction factor will be derived from the measurements with different rail pads, rail fastening systems, wagon type and speeds and will be applied during the analysis so that the collected data can be examined most efficiently.

Expected results

The results of the project will reflect the real operating conditions and the position of the sector. The UIC and its members plan to make the first announcement of results by participating in the UIC Noise Days event on 28 February to 1 March 2023.

OUT NOW: The Definitive Guide to Rail’s Digital Future

The rail industry is undergoing a digital revolution, and you need to be ready. We have released our latest market report, “Track Insight: Digitalisation.”

This is not just another report; it’s your comprehensive guide to understanding and leveraging the profound technological shifts reshaping our industry. We move beyond the buzzwords to show you the tangible realities of AI, IoT, and advanced data analytics in rail.

Discover how to:

- Optimise operations and maintenance with real-time insights.

- Enhance passenger services through seamless, high-speed connectivity.

- Leverage technologies like LEO satellites to improve safety and efficiency.

Featuring expert analysis from leaders at Nomad Digital, Lucchini RS, Bentley Systems and more, this is a must-read for any rail professional.